Ball screw performance test bench based on motor servo loading

A technology of ball screw and ball screw pair, which is applied in the field of ball screw pair performance test device, can solve the problems of low loading accuracy, complex structure of loading device, unstable loading process, etc., achieve wide speed regulation range, mechanical assembly Compact, easily measured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The application principle of the present invention will be further described below with reference to the drawings and specific embodiments.

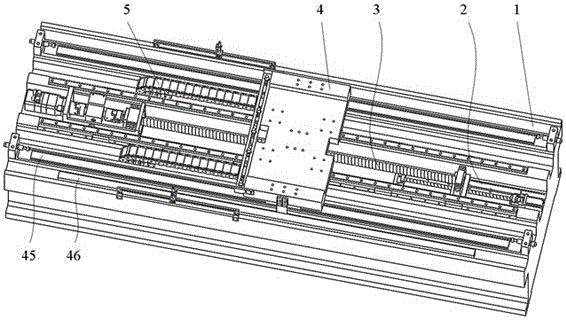

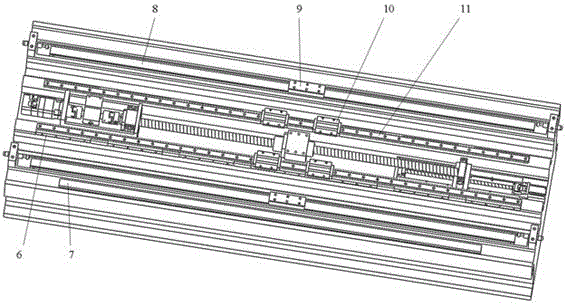

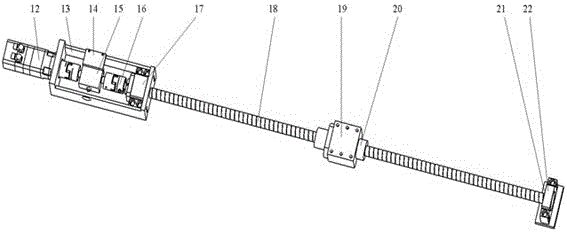

[0031] Such as figure 1 , As shown in 2, the ball screw performance test bench based on motor servo loading of the present invention includes bed 1, rolling guide 11 and guide rail slider 10, guide rail pressure plate 6, load front support 13, and load rear support 21 , Workbench 4, Drive ball screw pair 2, Load ball screw pair 3, Provide dynamic load linear motor 45, Load AC servo motor 12, Linear scale 46 for measuring linear displacement, Photoelectric sensor for zero return 38, A buffer 42 to ensure test safety, a torque sensor 15 to measure friction torque, and an infrared temperature sensor 39 to collect temperature.

[0032] The rolling guide 11 is fixedly installed on the upper end surfaces of the left and right sides of the middle groove of the bed 1, seven guide rail pressing plates 6 and the bed 1 are fixed and pressed again...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com