Water-removable microwave resonant cavity for steam humidity measurement

A microwave resonant cavity and steam humidity technology, which is applied in the field of testing, can solve the problems of reduced steam turbine stage efficiency, reduced measurement accuracy, and increased dielectric loss, and achieves the effects of simple structure, reduced measurement error, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

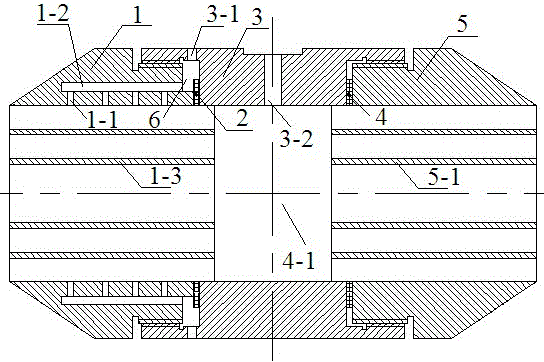

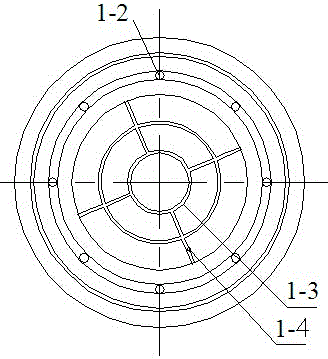

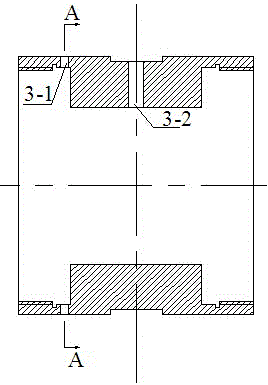

[0015] Depend on Figure 1-Figure 4 The shown microwave resonant cavity for steam humidity measurement, which can remove water film, includes steam flow inlet pipe 1, resonant cavity pipe 3 and frequency adjustment pipe 5, which are threaded from front to back, steam flow inlet pipe 1, resonance The cavity tube 3 and the frequency adjustment tube 5 are both front and rear transparent tubes, and the tube holes of the three are connected in sequence, and the steam flow inlet tube 1, the resonant cavity tube 3 and the frequency adjustment tube 5 are arranged coaxially. The wall surface of the front outer ring of the steam flow entering tube 1 and the rear outer ring wall surface of the frequency adjustment tube 5 are conical surfaces, and the front outer ring wall surface of the steam flow entering tube 1 is a conical surface with the front end shrinking inward. , the wall surface of the outer ring at the rear of the frequency adjustment tube 5 is a conical surface with the rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com