Pro/E based ground of cutter-suction dredger reamer parametric design method

A cutter suction dredger, parametric design technology, applied in the direction of calculation, electrical digital data processing, special data processing applications, etc., can solve the problems of long design cycle, unreasonable cutter structure, low efficiency, etc., to reduce Duplication of labor, the effect of improving design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

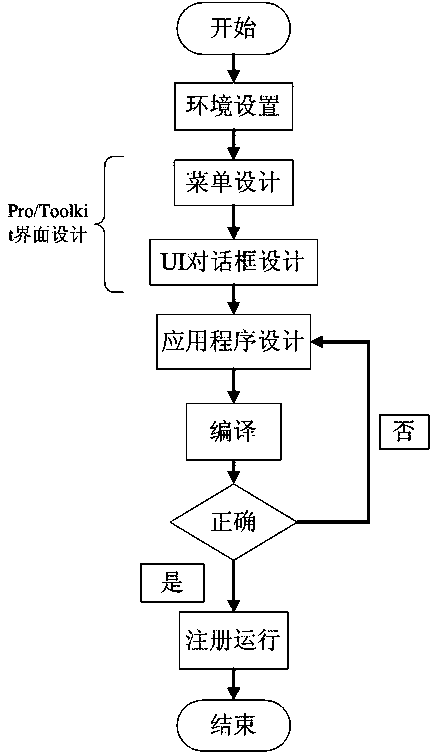

[0041] Such as figure 1 Shown, the parametric design method of a kind of cutter suction dredger reamer based on Pro / E of the present invention comprises the following steps:

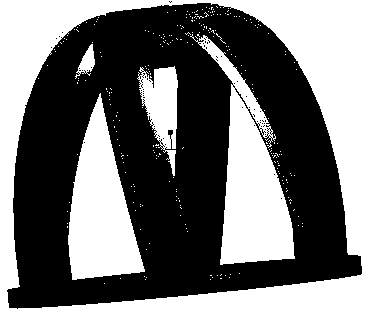

[0042] 1. Establish a 3D parametric model of cutter suction dredger cutter

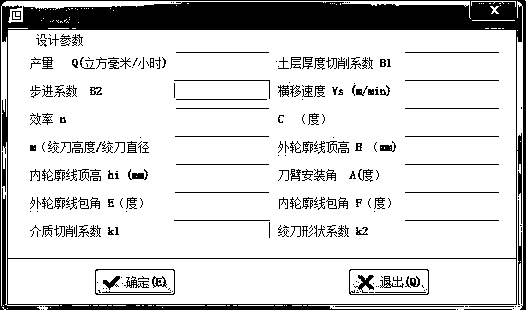

[0043] The main design parameters of the reamer are shown in Table 1:

[0044] Table 1 Main parameters of reamer design

[0045]

[0046] There are many parameters that affect the reamer and are complex and changeable, including the type and state of rock and soil, the output requirements of the dredger, the thickness of the cutting soil layer, the traverse speed and the rotational speed, etc. The relationship between the parameters is shown in the following formula:

[0047] Q = 60 B 1 B ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com