Resistance changing structure for electro-hydraulic starter rheostat

A starter and electro-hydraulic technology, applied in the direction of liquid resistors, electric/electric converters, starter parts, etc., can solve the problems of low efficiency of high current, rust of mechanical structure, and great waste of electric energy, etc., to achieve maintenance The effect of extending the cycle, preventing water loss, and easy and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

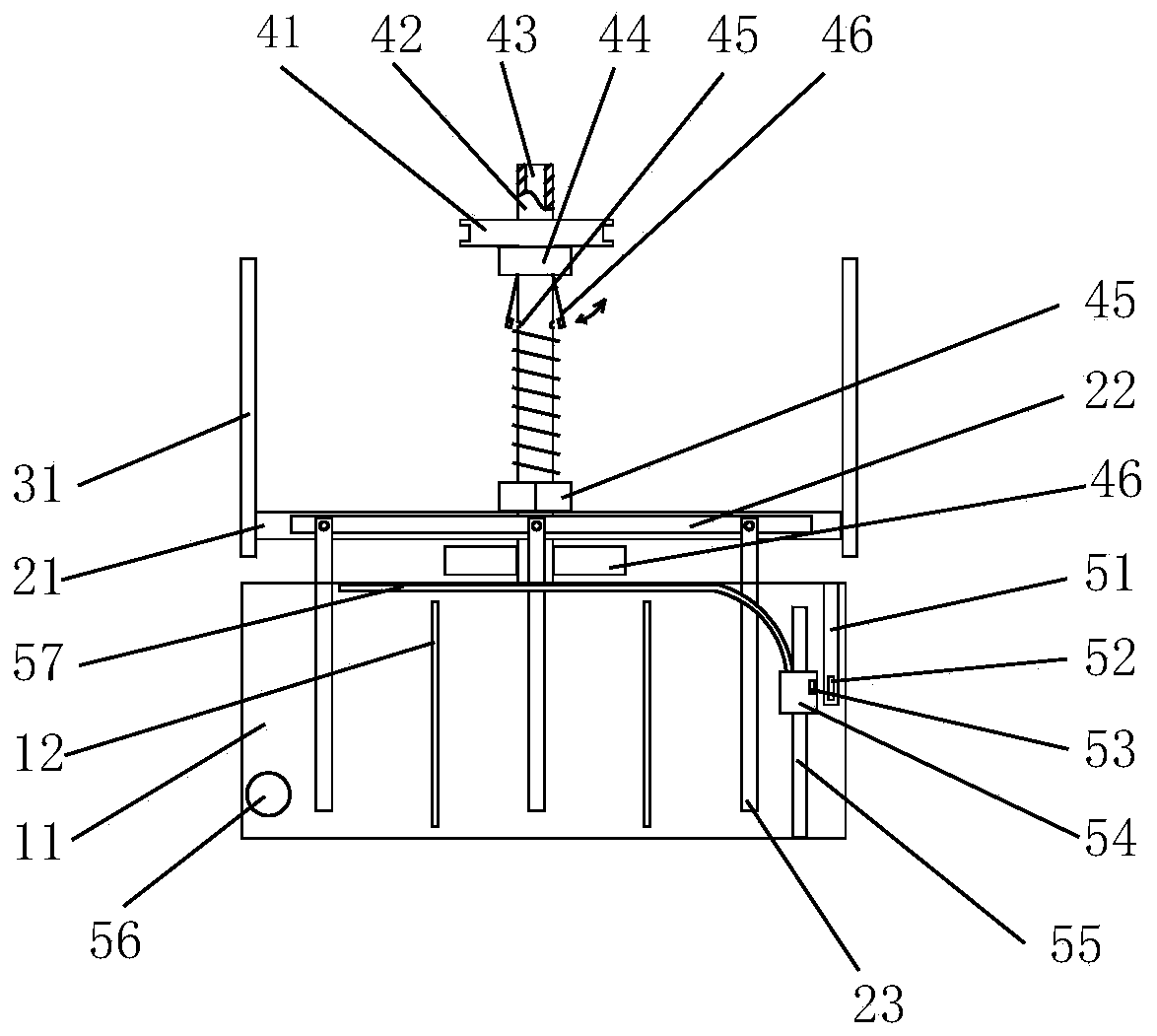

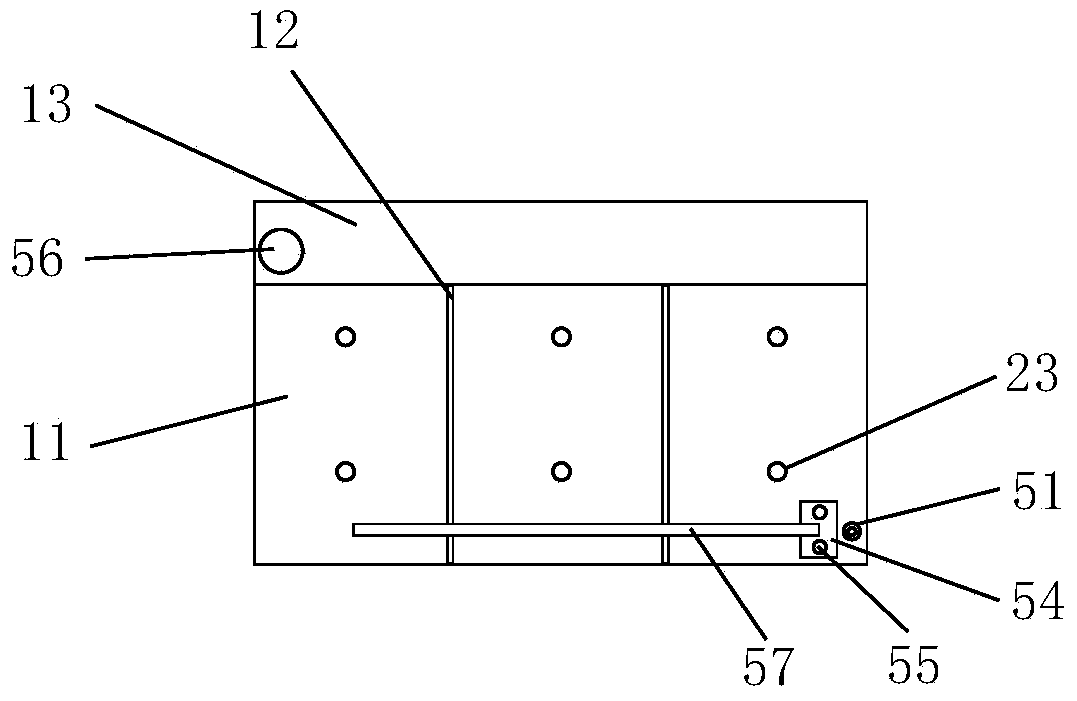

[0042] Now in conjunction with accompanying drawing, the present invention will be further described:

[0043] As shown in the figure, the water tank 11 is used as a water resistance;

[0044] Three pairs of electrode rods 23 are connected to water resistors and can output three resistance values;

[0045] The electrode rod lifting structure can simultaneously control the movement of one of each pair of electrode rods 23, thereby changing the water resistance;

[0046] The electrode rod lifting structure includes:

[0047] Screw rod 42, two ends are respectively fixed on the frame by upper bearing 44 and lower bearing 46;

[0048] Nut 45 cooperates with screw rod 42;

[0049] Insulation frame 21 is fixed with nut 45;

[0050] An electrode plate 22 is fixed to one of each pair of electrode rods 23;

[0051] Another one of every pair of electrode rods 23 is fixed on the frame by an insulating plate;

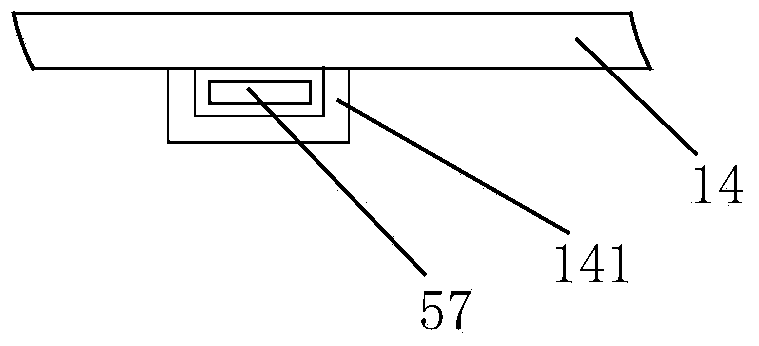

[0052] Guide rail 31, is provided with two, is fixed on the frame, can e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com