Liquid tobacco composition and method for its manufacture

A tobacco composition, a tobacco technology, applied in directions such as tobacco, tobacco processing, and cigar manufacturing, can solve problems such as efficiency or effectiveness, adverse effects of tobacco physical or chemical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

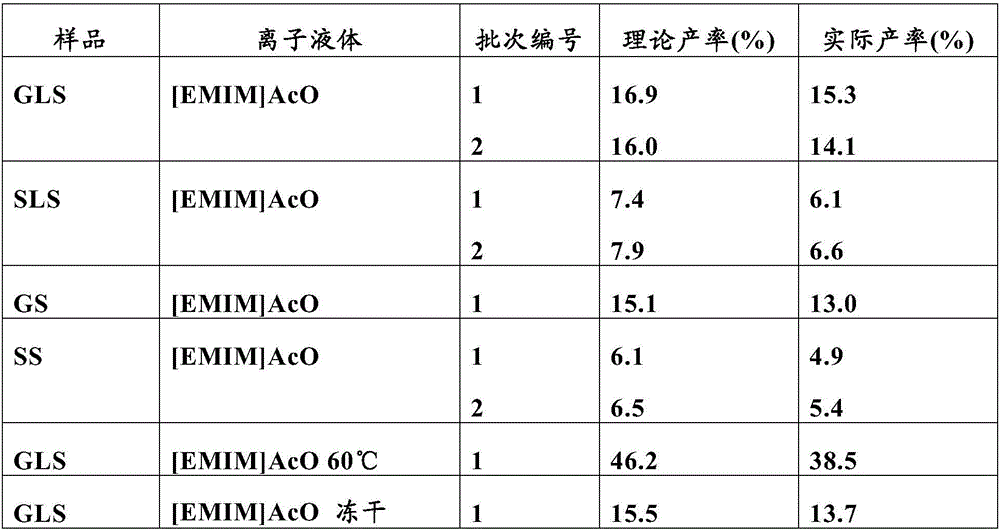

[0044]In one embodiment, dissolution of tobacco in an ionic liquid and regeneration of tobacco fibers from the ionic liquid is performed. It is understood that other ionic liquids and conditions can be used to dissolve tobacco and other methods for regeneration can also be used. In this example, tobacco shreds were suspended in 1-ethyl-3-methylimidazolium acetate (several shreds per milliliter) and heated slightly by a heat gun. Within 30 minutes, the tobacco shreds were completely dissolved in the liquid. A drop of tobacco dissolved in ionic liquid was dropped on a glass slide, and a drop of water was added to the slide, tobacco fiber regrowth was observed at the water / ionic liquid boundary.

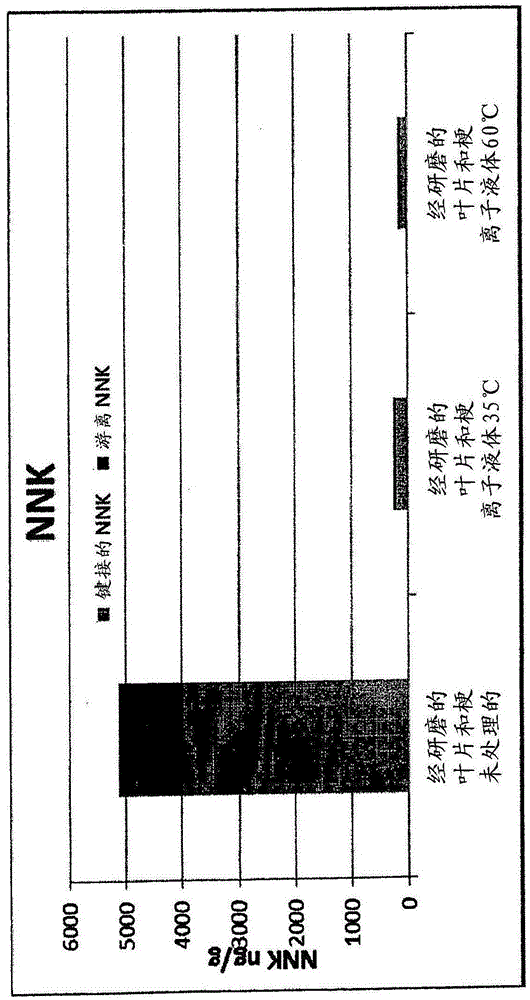

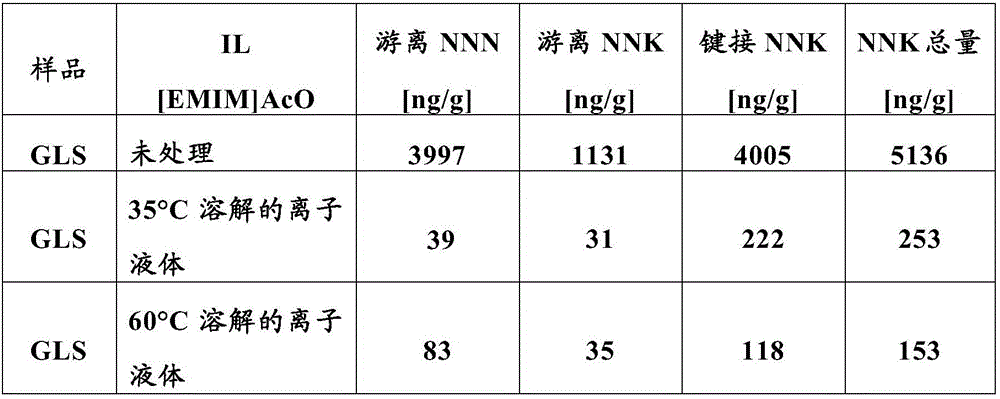

[0045] In another experiment, reducing sugars were extracted from a liquid tobacco composition (tobacco shreds dissolved in 1-ethyl-3-methylimidazolium acetate) or undissolved tobacco shreds using an acetic acid solution. The reducing sugar extracted from the acetic acid solution reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com