Welded structure

A welding structure and fillet welding technology, which is applied to welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of reduced production capacity, increased manufacturing cost, and increased calendering load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

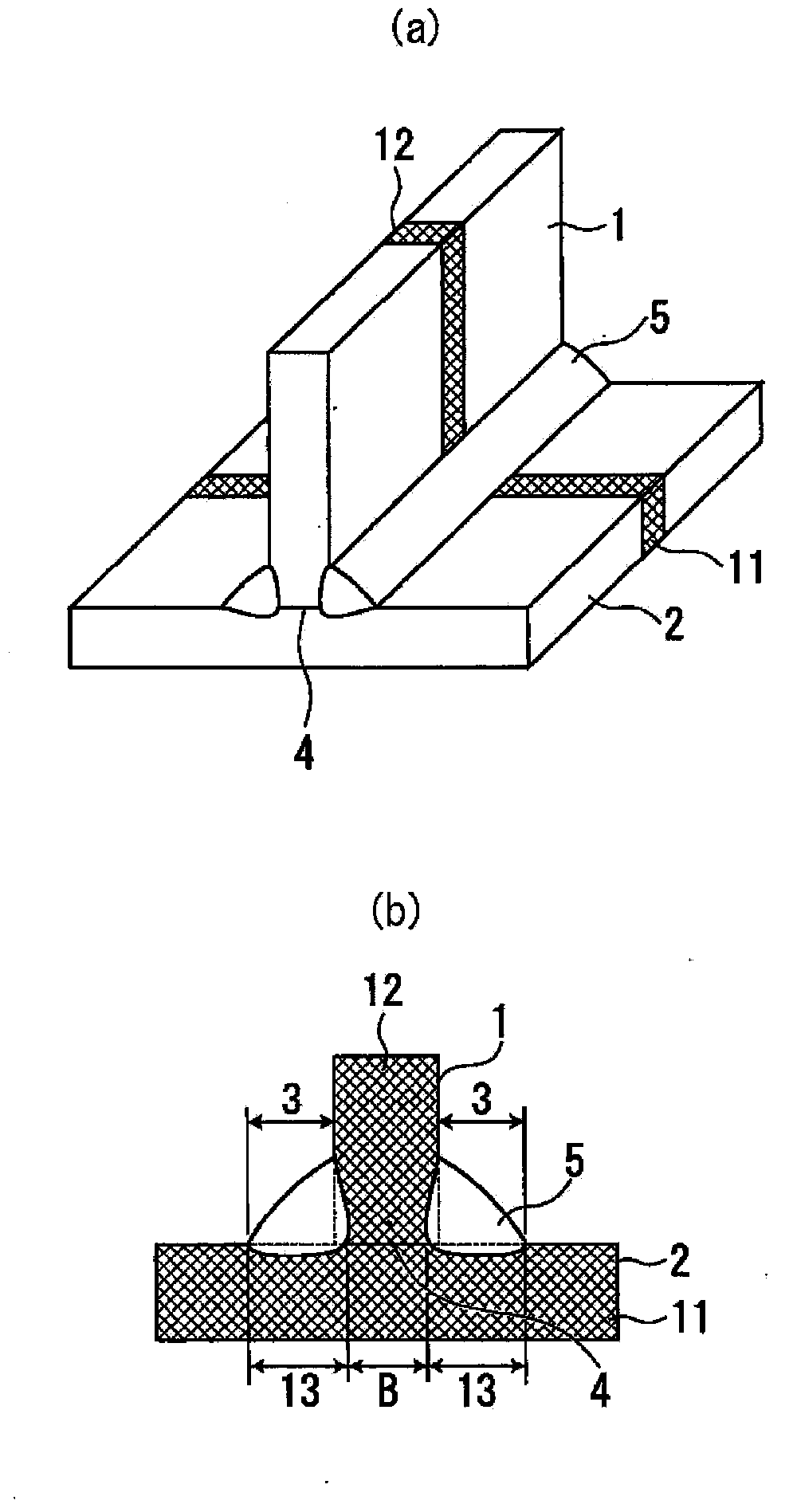

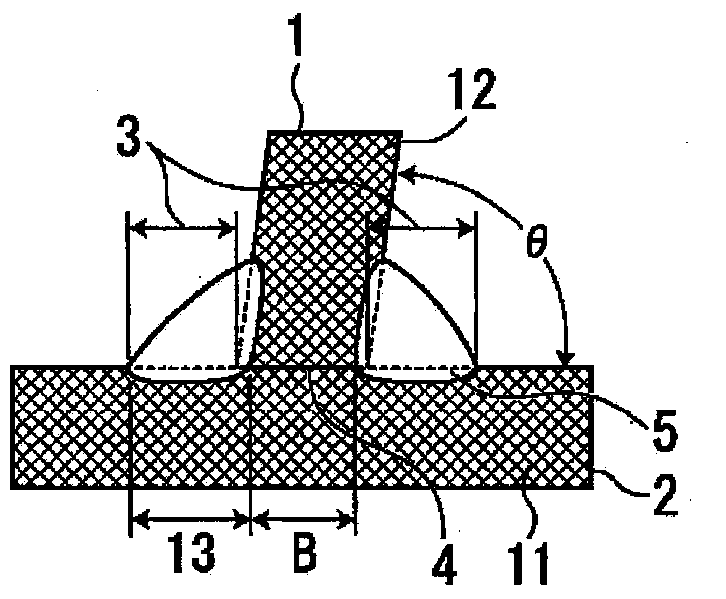

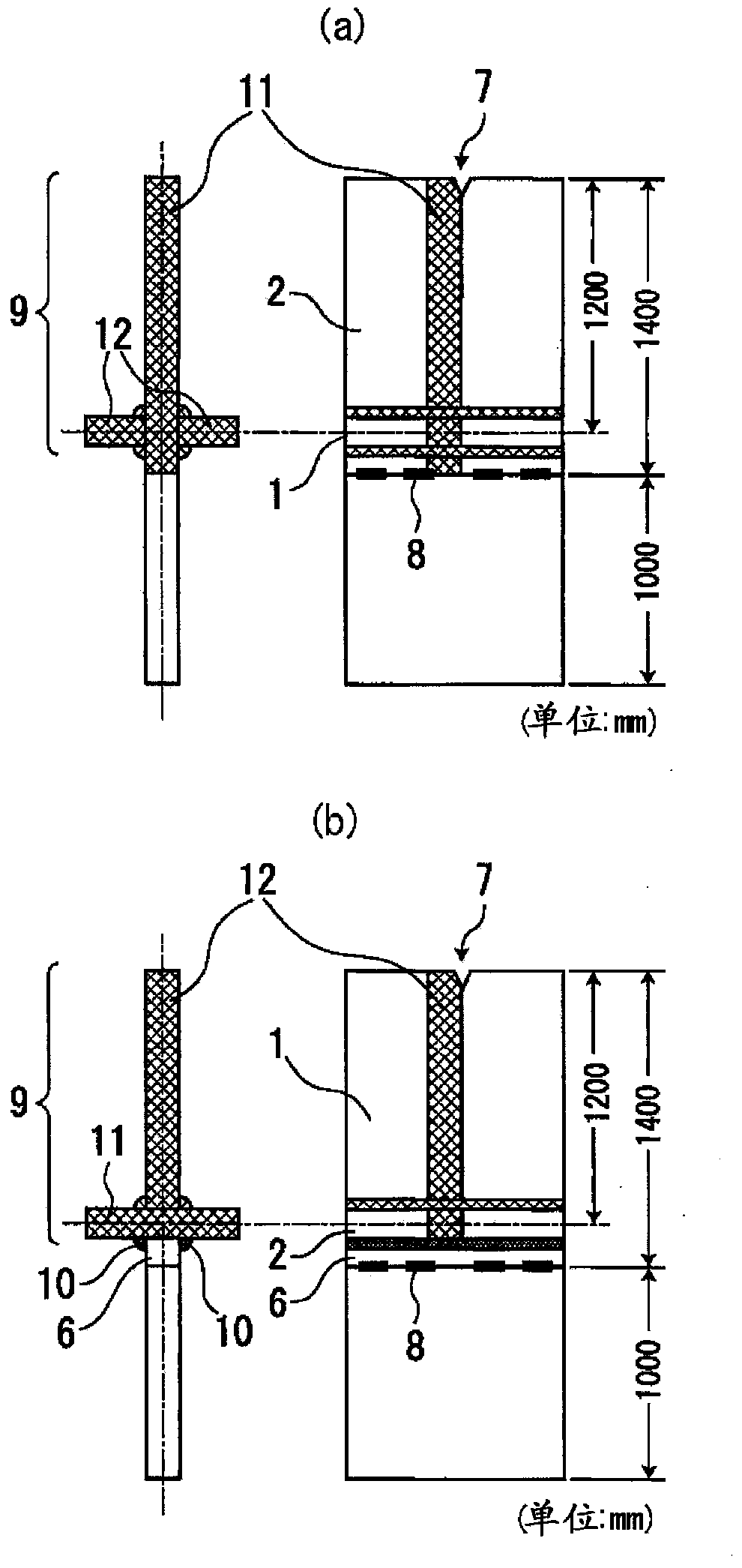

[0111] A thick steel plate having the plate thickness and low temperature toughness shown in Tables 1 and 2 was used to fabricate butt welded joints with the welding heat input shown in Tables 1 and 2 using the welding methods shown in Tables 1 and 2, and they were formed to be joined. Part 2. Joining part 1. In addition, the butt welding adopts the welding heat input shown in Tables 1 and 2, single-pass high-energy gas arc welding (SEGARC and 2-electrode SEGARC) or multilayer CO 2 Welding is performed by changing the welding material.

[0112] From the joint parts and the butt-welded heads of the parts to be joined, the surface of the test piece is 1mm or 2mm below the surface, the longitudinal direction of the test piece is perpendicular to the tangent line, and the notch faces the direction perpendicular to the tangent line. The central part of the weld metal and the heat-affected part (BOND part) have obtained V-notch Charpy impact test pieces (10mm thick).

[0113] The Charpy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com