Film forming method

A film forming method and film thickness technology, applied in ion implantation plating, coating, instruments, etc., can solve the problems of decreased adhesion of the antifouling layer, shortened processing time, and waste of processing time, achieving manufacturing cost reduction, Realize the effect of reducing manufacturing cost and removing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

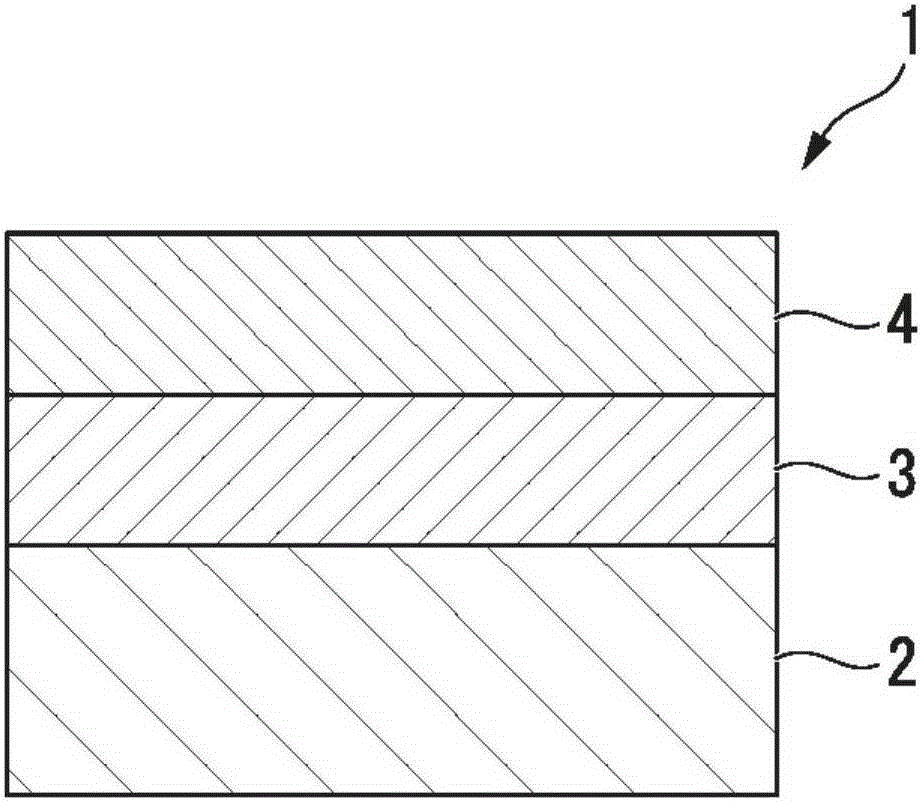

[0166] With the film forming apparatus according to Embodiment 1, after vapor deposition was performed so that the film thickness of the vapor deposition film serving as the antifouling layer 4 was 5 nm, the laminated structure 1 was formed without performing the finishing process. In addition, the conditions which are not described are the conditions corresponding to those described in Embodiment 1.

experiment example 2

[0168] As the finishing process, the temperature: 40° C., humidity: 80%, and time: 2 hours in a constant temperature and humidity furnace were used to form a laminated structure under the same conditions as in Experimental Example 1 except this point.

experiment example 3

[0170] As a finishing process, the temperature in a constant temperature and humidity furnace: 40°C, humidity: 80%, and time: 2 hours are performed, and then, as a removal process, the surface of the laminated structure 1 is wiped, except for this point. The laminated structure 1 was formed under the same conditions as in Experimental Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com