Rapid low-temperature microwave thawing method and thawing device

A microwave thawing machine, low temperature technology, applied in the direction of preservation of meat/fish by freezing/cooling, food preservation, food science, etc. quality and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

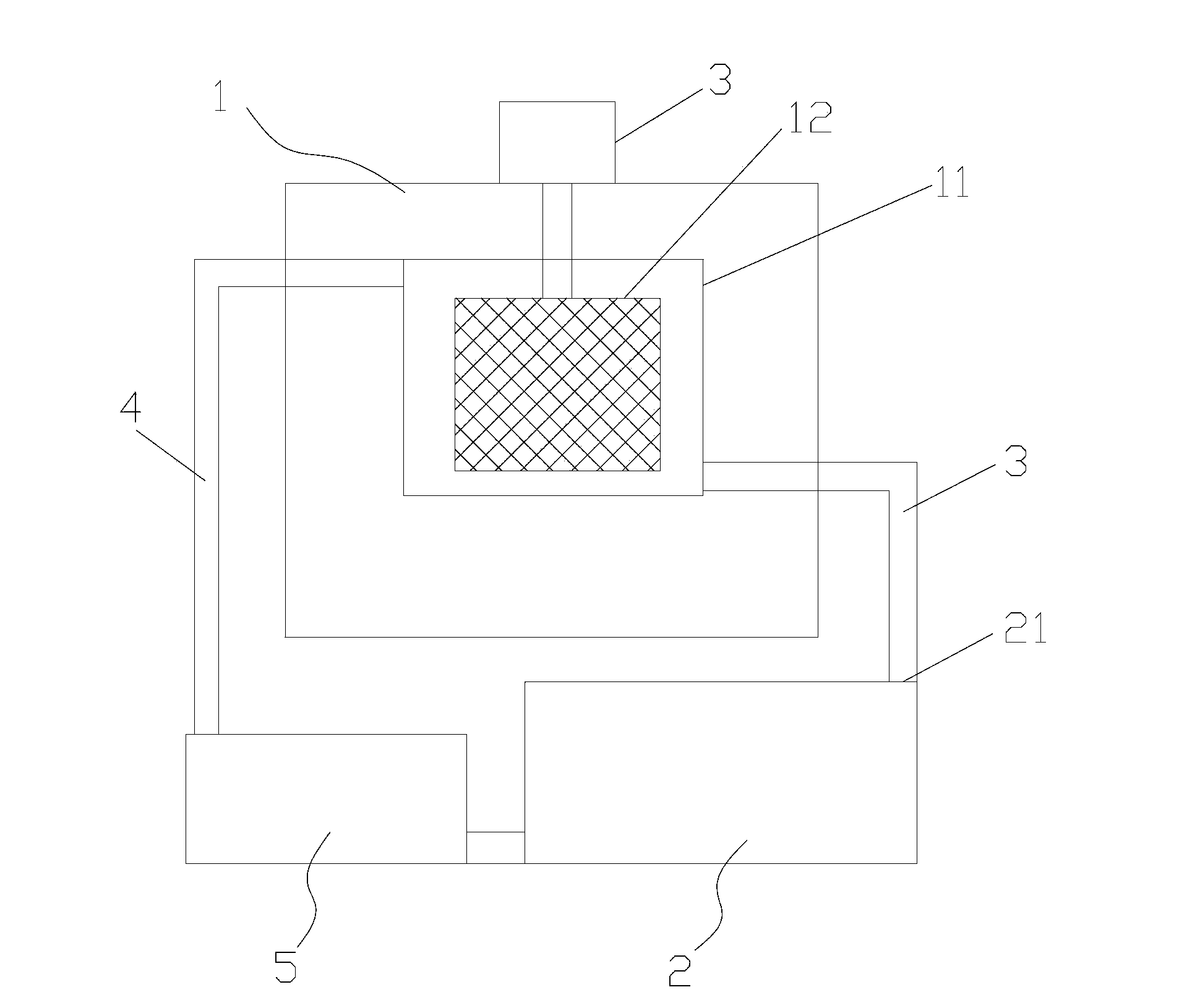

[0015] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0016] A rapid low-temperature microwave thawing method described in the present invention is carried out by using a microwave thawing machine. The thawing method is as follows: the quick-frozen food is placed in the thawing container of the microwave thawing machine, and flowing low-temperature water is passed through the thawing container, and then opened Microwave to defrost. A preferred solution is that the temperature of the flowing low-temperature water is -2°C-5°C low-temperature water, that is, frozen items are kept immersed in a low-temperature water environment of -2°C-5°C for thawing. Thawing in a low-temperature water environment of -2°C to 5°C is especially suitable for thawing quick-frozen food, which can keep fresh and thaw quickly. During the thawing process, the intensity and time of the microwave, the flow rate of the low-tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com