Large-flux cell sound sorting chip

A large-throughput, sorting technology, applied in biochemical instruments, biochemical equipment and methods, laboratory equipment, etc., can solve low-throughput bottlenecks and other problems, achieve reduced energy loss, increased strength, and avoid corner effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

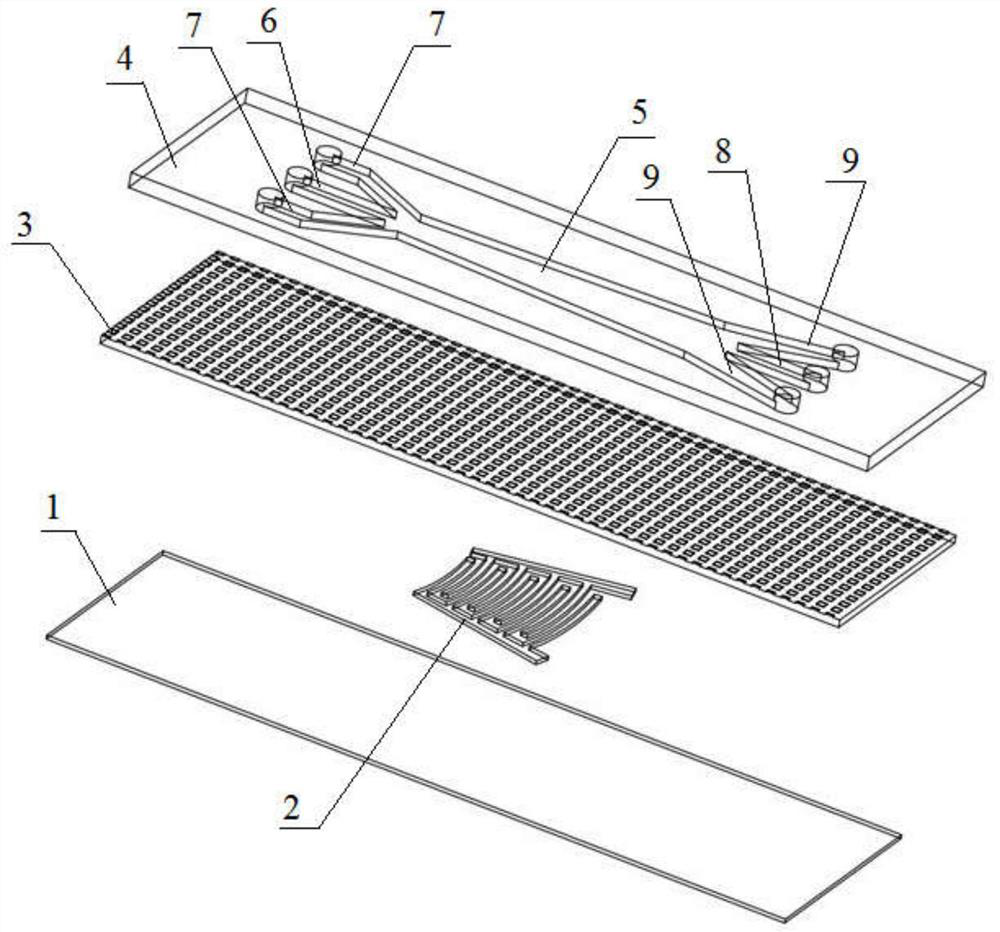

[0028] The large-throughput cell acoustic sorting chip provided by the present invention includes a piezoelectric substrate 1, an interdigital transducer 2, a sorting channel substrate 3 and a sorting channel 4, wherein the interdigital transducer 2 is sputtered on On the piezoelectric substrate 1, the sorting channel 4 is sputtered on the sorting channel substrate 3, from bottom to top, the piezoelectric substrate 1, the interdigital transducer 2, the sorting channel substrate 3 and the sorting flow channel Lane 4 is set in turn.

[0029] The piezoelectric substrate 1 is made of lithium niobate single crystal material.

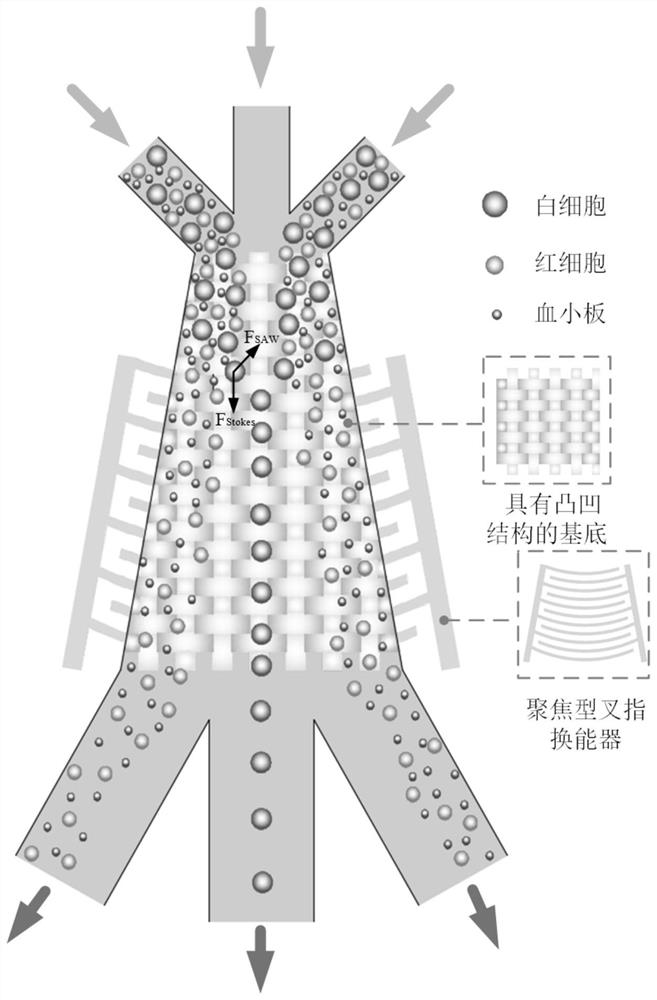

[0030] The shape of the interdigital transducer 2 is arc-shaped, and the arc-shaped interdigital transducer 2 is a focusing type interdigital transducer. The central axis of the interdigital transducer 2 and the central axis of the upper sorting channel 4 Correspondingly, the sorting channel base 3 is a sorting channel base 3 with an insulating layer of a co...

Embodiment 2

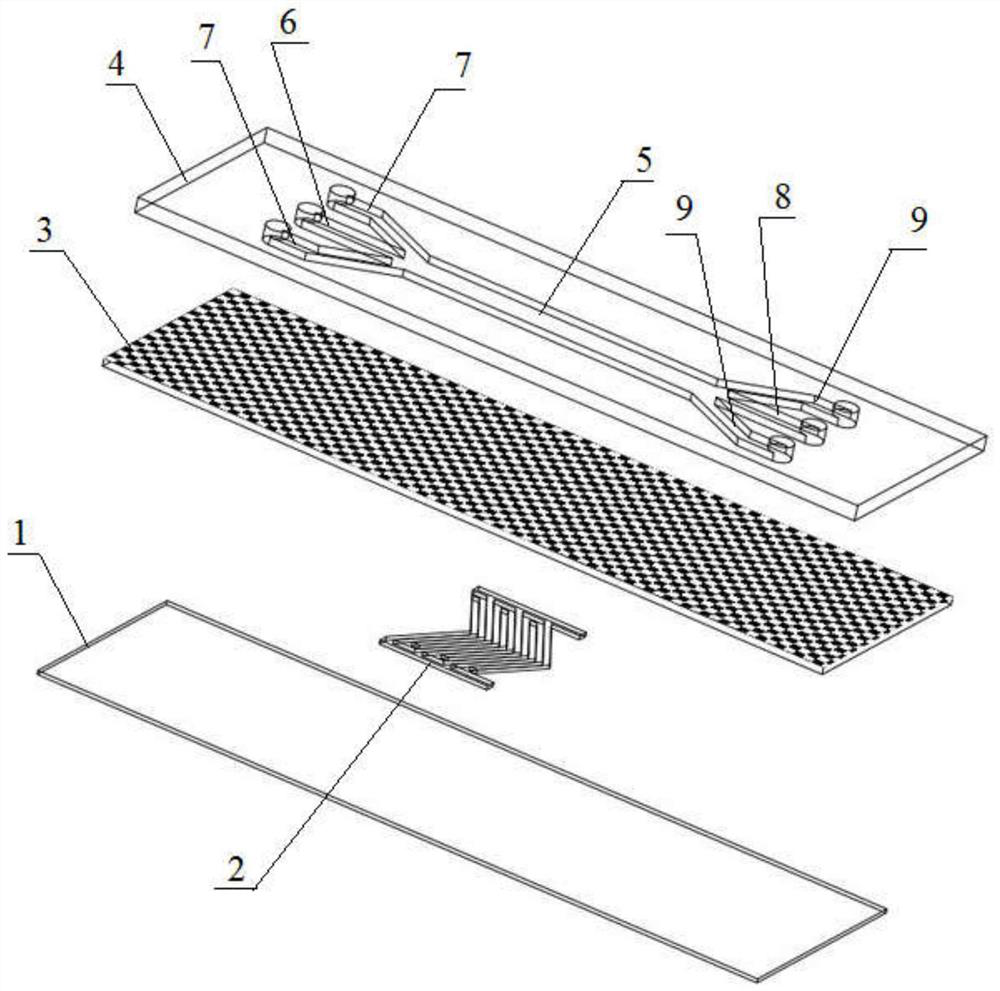

[0034] The large-throughput cell acoustic sorting chip provided by the present invention includes a piezoelectric substrate 1, an interdigital transducer 2, a sorting channel substrate 3 and a sorting channel 4, wherein the interdigital transducer 2 is sputtered on On the piezoelectric substrate 1, the sorting channel 4 is sputtered on the sorting channel substrate 3, from bottom to top, the piezoelectric substrate 1, the interdigital transducer 2, the sorting channel substrate 3 and the sorting flow channel Lane 4 is set in sequence.

[0035] The piezoelectric substrate 1 is made of lithium niobate single crystal material.

[0036] The shape of the interdigital transducer 2 is arrow-shaped, and the arrow-shaped interdigital transducer 2 is a focusing-type interdigital transducer. The axes are arranged correspondingly, the sorting channel base 3 is a sorting channel base with optimized wettability, and the regional wettability structures on the sorted channel base 3 with opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com