Blighted grain dust remover

A technology of dust collector and sloping valley, which is applied in chemical instruments and methods, solid separation, and separation of solids from solids by air flow, etc. The effect of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

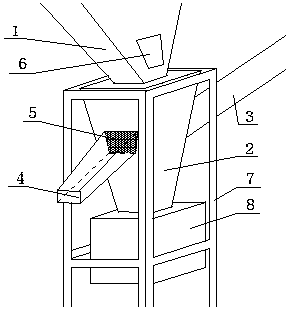

[0015] Such as figure 1 As shown, the present embodiment provides a grain dust collector, comprising a feed hopper 1, a dust removal bin 2, an air duct 3, a blower and a dust outlet duct 4, and the top of the dust removal bin 2 communicates with the feed hopper 1, so The side of the dust removal bin 2 is provided with a dust outlet and an air inlet, the bottom of the dust removal bin 2 is provided with a discharge port, the dust outlet pipe 4 is connected to the dust outlet of the dust removal bin 2, and the dust outlet The mouth is provided with filter screen 5, and described filter screen 5 is length 22cm-28cm, preferably 26cm, width 13-17cm, the metal filter screen 5 of preferred 15cm, the mesh aperture of described filter screen 5 is 0.8-1.1mm, preferably 1.0 mm, the air inlet is connected with the wind pipe 3, and the wind pipe 3 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com