Nodularizing ladle cover

A technology of spheroidizing cover and spheroidizing bag, applied in the field of spheroidizing bag, can solve the problems of affecting the sealing performance, damage to the pouring port, too large height difference, etc., so as to improve the high temperature resistance performance, improve the service life, and ensure the operation safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

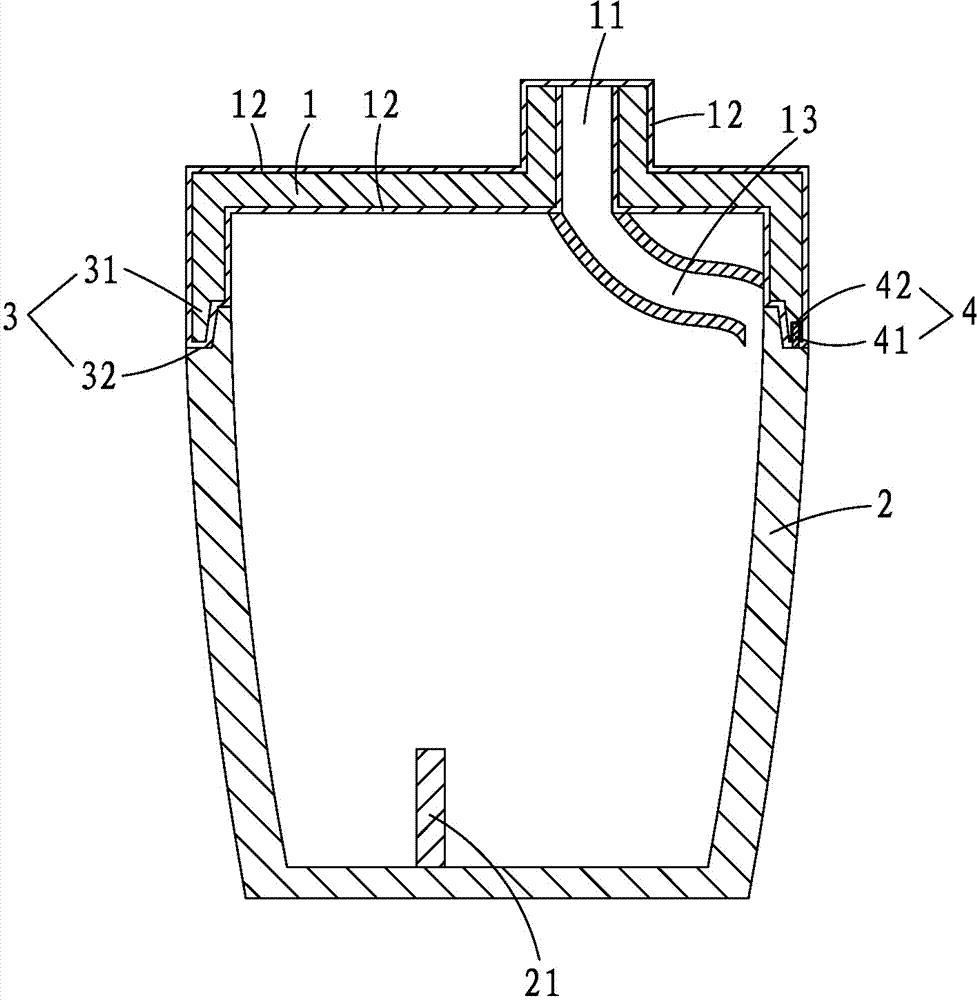

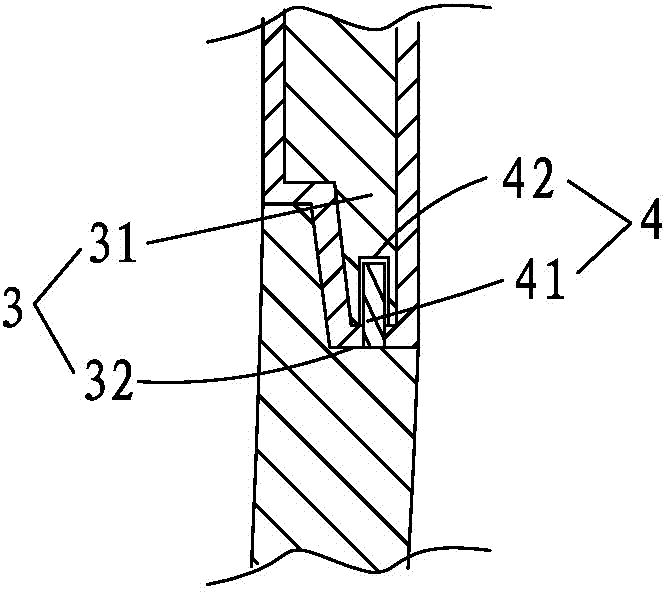

[0015] Such as figure 1 As shown, the spheroidizing bag cover 1 of the present invention is covered on the spheroidizing bag 2, and a sprue 11 is provided on the spheroidizing bag cover 1, and a layer of fire-resistant The material layer 12 is to isolate the high-temperature molten iron from direct contact with the spheroidizing ladle cover 1 and the sprue 11 itself, so that during the spheroidizing reaction, the high-temperature molten iron will not damage the sprue 11, and the splashed liquid will not adhere to the ladle. on the surface of the cover. And the spheroidizing ladle cover 1 is also provided with a diversion groove 13 to connect the sprue 11 and the inner wall of the spheroidizing ladle 2, and is used to guide the high-temperature molten iron to the inner wall of the spheroidizing ladle 2, so as to slowly Slowly flow down until the spheroidization reaction occurs when the dam 21 is overflowed, so as to prevent the molten iron from splashing due to the height diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com