Fully automatic production line for double rib cylindrical flexible container bags

A fully automated, containerized bag technology, applied in the packaging field, can solve the problems of slow speed and low efficiency, and achieve the effect of even bag mouth, improved yield and efficiency, and smooth products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

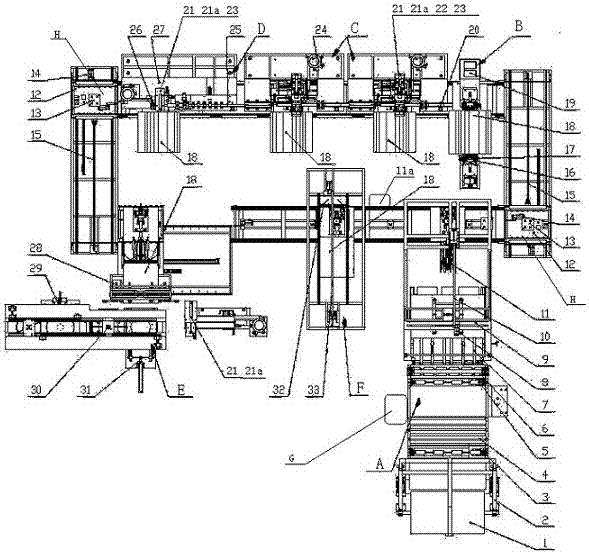

[0023] Such as figure 1 As shown, the present invention is a fully automated production line for double-striped cylindrical flexible container bags. The production line includes a feeding mechanism A, a crimping mechanism B, a sling mechanism C, a waist hoop mechanism D, a bottom bag mechanism E, and a blanking mechanism F, programmable logic controller G, reversing mechanism H, motor 11a, automatic sewing machine 21, XY working platform 23, stepping motor 21a, rotary drum mechanism 28, transport trolley 11, tensioning device 18, the curling Mechanism B, 2 sets of sling mechanisms C, and waist hoop mechanism D are sequentially connected in a straight line, the bottom bag mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com