Kitchen waste treatment method and device

A technology of kitchen waste and treatment device, which is applied in the fields of filtration treatment, chemical instruments and methods, and multi-stage treatment of water/sewage, etc. It can solve the problem of effectively controlling the quantity of oil that cannot be taken and its whereabouts, the low degree of automation of the separation system, and the problem of oil and water. Problems such as unsatisfactory sedimentation and stratification, to achieve the effect of favorable separation, good trial effect and moderate oil pumping speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

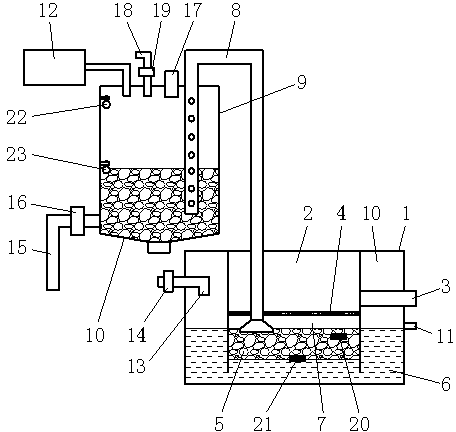

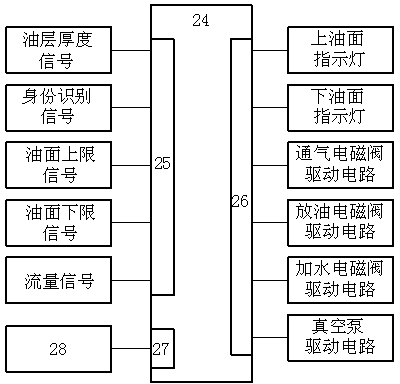

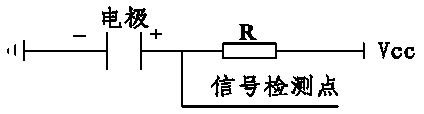

[0025] The present invention mainly includes three parts: classification collection device 1, oil storage tank 9 and control circuit. The optimal design for the classification collection device 1 is to set the slag collection grid 2, the oil collection grid 7 and the overflow grid 10 in the classification collection device box to effectively separate the impurities, oil and water in the kitchen waste. The specific structure is as figure 1 shown. Food waste is a mixture of oil, water and slag. The mixture of oil, water and slag is poured into the classification collection device 1 from the slag collection grid 2, and is relatively static and separated in the slag collection grid 2. The oil and part of the water enter the oil collection grid 7 . The slag in the slag collecting grid 2 can be directly discharged from the slag discharge port. The oil collecting grid 7 and the overflowing grid 10 adopt the principle of a connecting device, and the bottom is connected. The oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com