Method for extracting naringenin from grapefruits

A technology for naringenin and grapefruit, applied in the field of naringenin extraction, can solve the problems of high energy consumption, low extraction rate and long time consumption of naringenin, and achieve the effects of short time consumption, high extraction rate and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

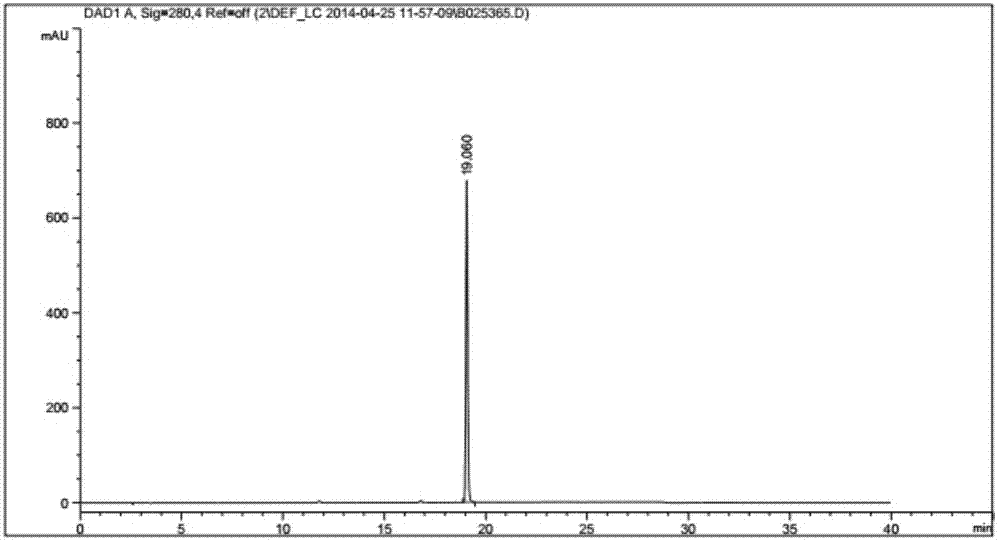

[0035] Take the dried pomelo fruit, crush it through a 10-mesh sieve, take 160kg of the undersieve, and put it into 1600L hot water heated to 85°C, continue heating to 100°C, and keep the temperature for extraction for 1.5 hours. The extract was separated, and the filter residue was heated to 100°C with 1600L of 85°C water for extraction for 1.5 hours. The extract was separated and combined with the first extract. Pass the combined extracts through a decanter centrifuge with a rotating speed of 12000 R / min to remove mechanical impurities. After the centrifuge liquid is cooled below 60°C, it is filtered with an ultrafiltration membrane to remove macromolecular impurities. The inlet pressure of the ultrafiltration membrane is 0.25MPA, the outlet pressure is 0.14MPA, and the flow rate is 80M 3 / H. The liquid passing through the membrane is then concentrated by the membrane, the pressure of the solution entering is 0.9Mpa, and the pressure of the solution exiting is 0.45Mpa. Fi...

Embodiment 2

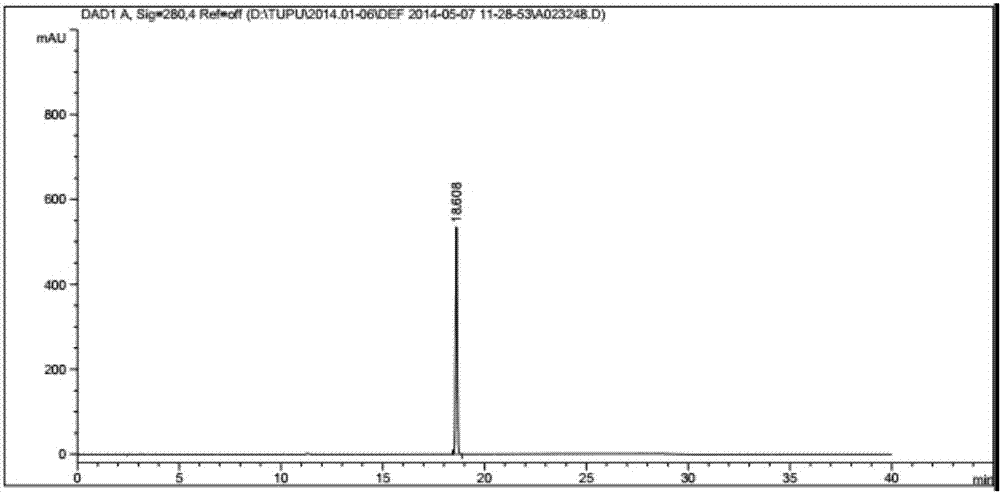

[0037] Take the dried pomelo fruit, crush it through a 10-mesh sieve, remove 200kg of the sieve, and put it into 2000L hot water heated to 85°C, continue to heat to 100°C, and keep this temperature for extraction for 1.5 hours. The extract was separated, and the filter residue was heated to 100°C with 2000L of 85°C water for extraction for 1.5 hours. The extract was separated and combined with the first extract. Pass the combined extracts through a decanter centrifuge with a rotating speed of 12000 R / min to remove mechanical impurities. After the centrifuge liquid is cooled below 60°C, use ultrafiltration membrane to filter out macromolecular impurities. The inlet pressure of the ultrafiltration membrane is 0.25MPA, the outlet pressure is 0.14MPA, and the flow rate is 80M 3 / H. The liquid passing through the membrane is then concentrated by the membrane, the pressure of the solution entering is 0.9Mpa, and the pressure of the solution exiting is 0.45Mpa. Finally, transfer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com