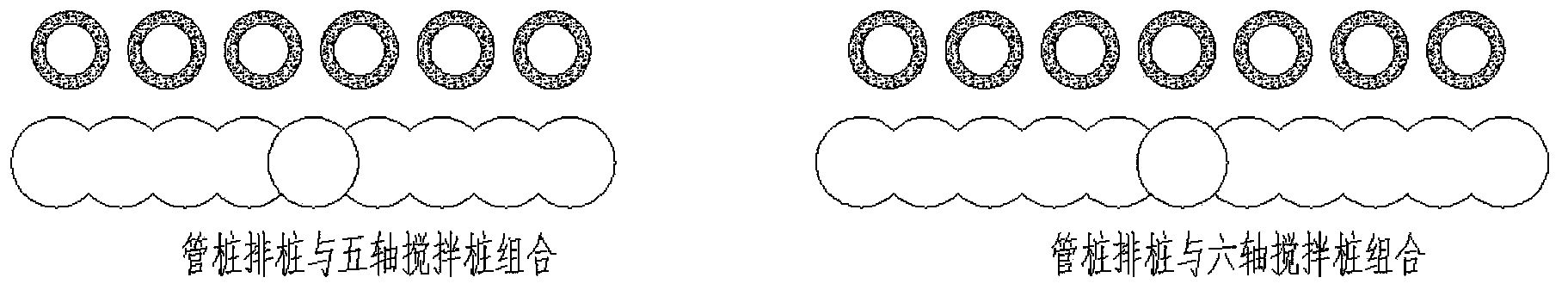

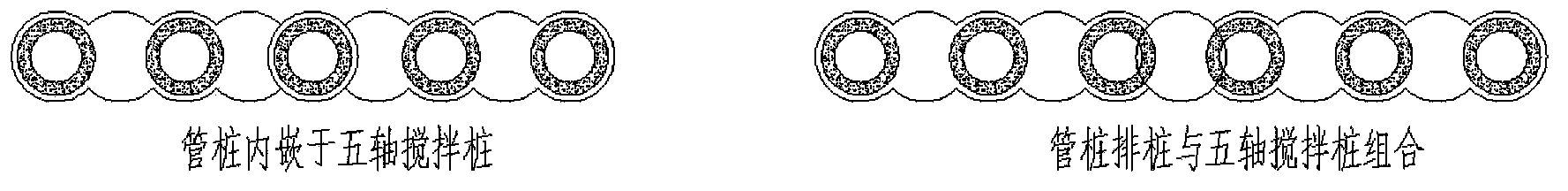

Envelope structure combining five (six) shaft mixing piles with precast tubular piles and construction method

A technology for prefabricated pipe piles and enclosure structures, which is used in infrastructure engineering, excavation, sheet pile walls, etc., can solve the problems of high rental cost of section steel, environmental pollution by mud, and high labor intensity, shortening the construction period and protecting surrounding areas. Environment, the effect of reducing construction difficulty and construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

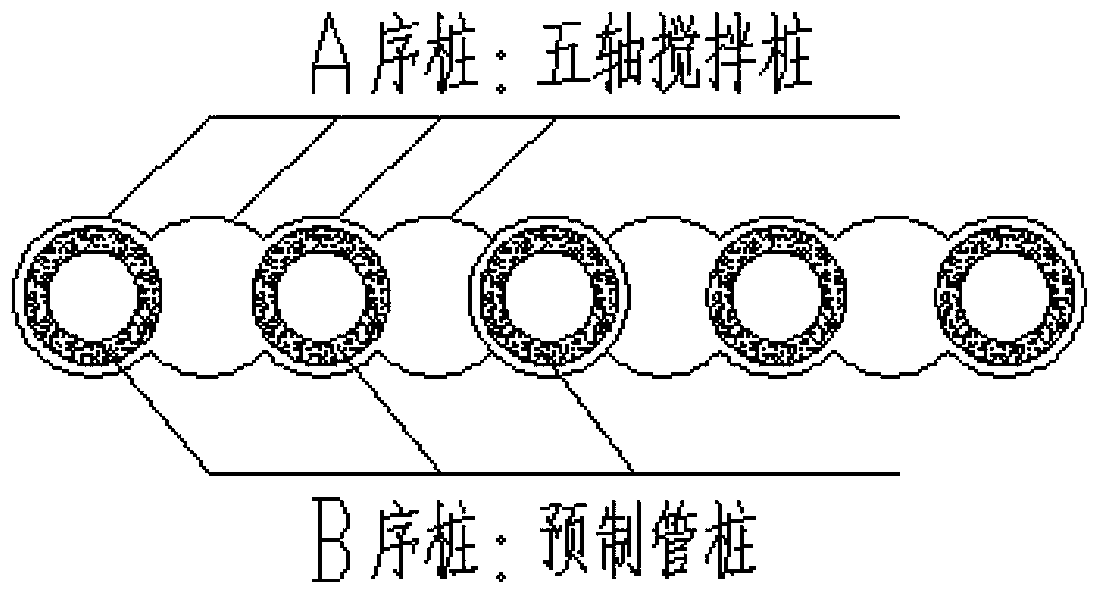

[0033] Such as image 3 As shown, a vertical enclosure structure in which pipe piles and stirring piles are engaged by the above-mentioned construction method includes a plurality of pipe piles and stirring piles. The specific construction process of A sequence pile is as follows:

[0034] (1) Stake out; open trenches; move the five-axis cement-soil mixing wall mechanical equipment to the position to be constructed.

[0035] (2) Start the background automatic cement slurry mixing system, and then send the cement slurry to the storage tank.

[0036] (3) Turn on the integrated computer, and the computer monitors the key data of the wall; the descending speed per meter, the lifting speed, the amount of slurry per meter, the design elevation of the wall end, the verticality, the total spraying amount and the total mixing time. Effectively control the quality of the wall.

[0037] (4) Turn on the power head to drive the multi-functional drill bit, spray the grout while stirring,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com