An anti-swelling and cracking safety protection device for the conveying pipe of a concrete wet spraying machine

A technology of safety protection device and wet spraying machine, applied in pipeline protection, safety valve, valve device and other directions, can solve problems affecting the development and promotion of pumping construction, reduce failure points, improve stability and reliability, The effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

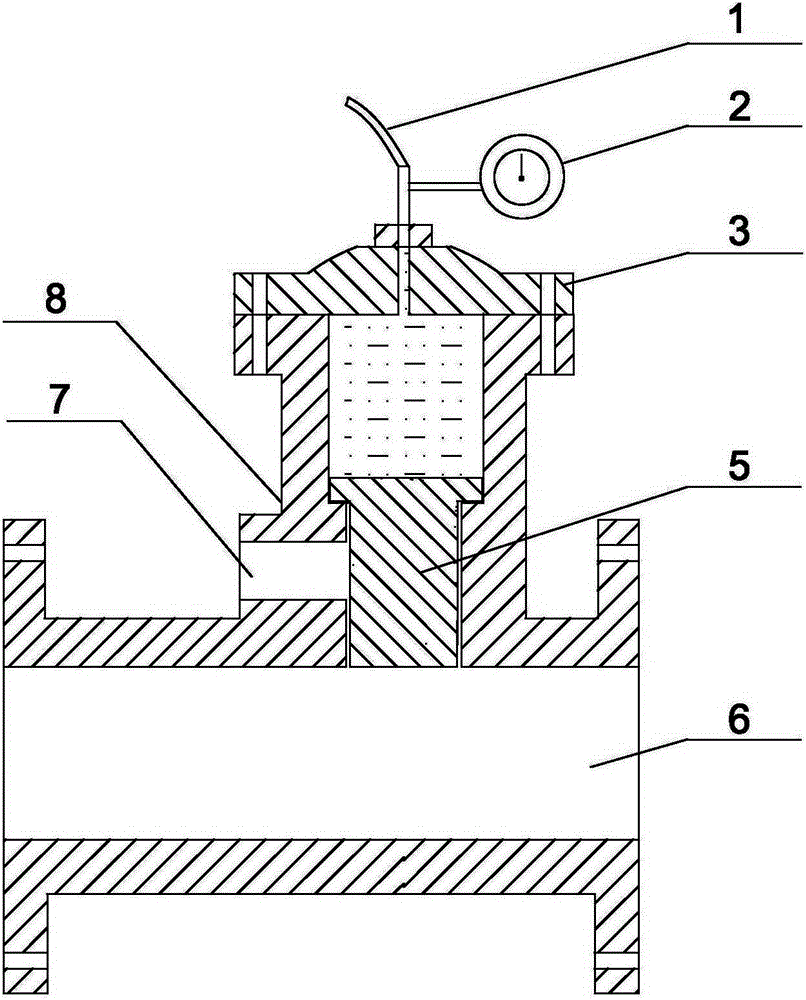

[0026] Such as figure 1 As shown, the concrete wet spraying machine conveying pipe anti-expansion cracking safety protection device of the present invention is installed between the wet spraying machine and the conveying pipe, and it includes a connecting pipe 6 with flanges at both ends and a hydraulic cylinder 8;

[0027] A through hole is opened in the upper position of the connecting pipe wall;

[0028] The pipe wall of the connecting pipe extends upward along the wall of the through hole to form a connecting nozzle with an open top. The hydraulic cylinder body is welded on the nozzle. The inner diameter of the nozzle is equal to the inner diameter of the hydraulic cylinder body. The inner wall is on the extension line of the inner wall of the nozzle;

[0029] A discharge hole 7 is provided on one side of the hydraulic cylinder body;

[0030] The top of the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com