A special hydraulic station for functional testing of hydraulic reversing valve and its testing method

A technology for hydraulic reversing valve and function testing, which is used in mechanical valve testing, liquid/vacuum measurement for liquid tightness, valve device, etc. It can solve the problem that the hydraulic station cannot match the function test of the hydraulic reversing valve, etc. To achieve the effect of ensuring safety, ensuring cleanliness and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

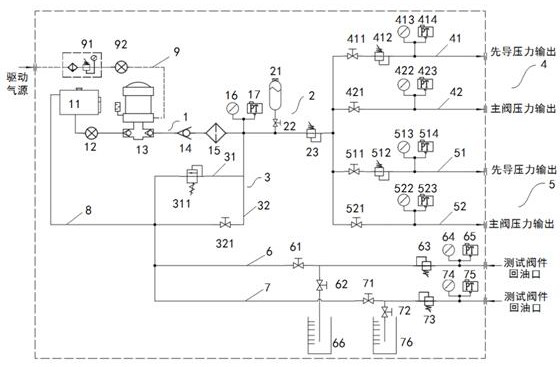

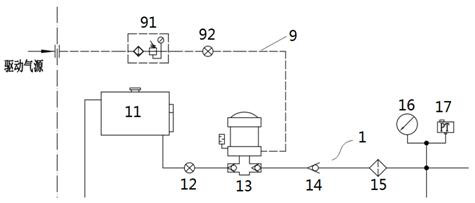

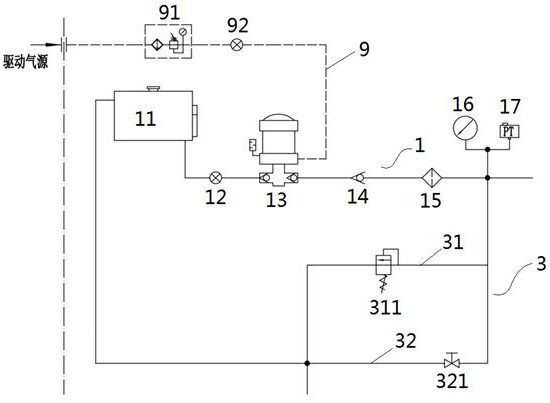

[0054] like figure 1 As shown, the present embodiment provides a special hydraulic station for the function test of the hydraulic reversing valve, which is especially suitable for an experimental device in which the back pressure of the oil return port simulates the underwater pressure environment and simultaneously tests the valve position switching function. Specifically, it includes: an oil source control branch 1 on which an oil tank 11 and a pneumatic pump 13 are arranged, and the output ends of the oil source control branch 1 are respectively connected to the inputs of the downstream pressure control branch 2 and the safety control branch 3 The output end of the downstream pressure control branch 2 is connected to the input end of the first hydraulic reversing valve test branch 4 and the second hydraulic reversing valve test branch 5, and the output end of the safety control branch 3 is connected to the total oil return branch The input end of the circuit 8, the output e...

Embodiment 2

[0068] Based on the special hydraulic station for the function test of the hydraulic reversing valve provided in Embodiment 1, the present embodiment provides a method for testing the function of the hydraulic reversing valve, which includes the following steps:

[0069] 1) Control and adjust the air source control branch, oil source control branch and downstream pressure control branch respectively to meet the internal pressure requirements of the underwater hydraulic reversing valve during operation or testing.

[0070] Specifically, open the air source stop valve on the air source control branch, so that the driving air source opens the pneumatic pump in the oil source control branch through the air source element; the pneumatic pump sends the hydraulic oil in the oil tank to the downstream pressure control branch; Observe the indication of the pressure gauge, and adjust the pressure reducing valve in the downstream pressure control branch to make the pressure in the pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com