Muck discharging gate system of spiral conveyor of earth pressure balance shield machine

A technology of screw conveyor and earth pressure balance, which is applied in the direction of earth drilling, mining equipment, mining equipment, etc., can solve the problems of increased resistance of the slag discharge ram, spewing over the square ground, and poor flow of slag to achieve Reduce the flow speed and avoid the effect of gushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing.

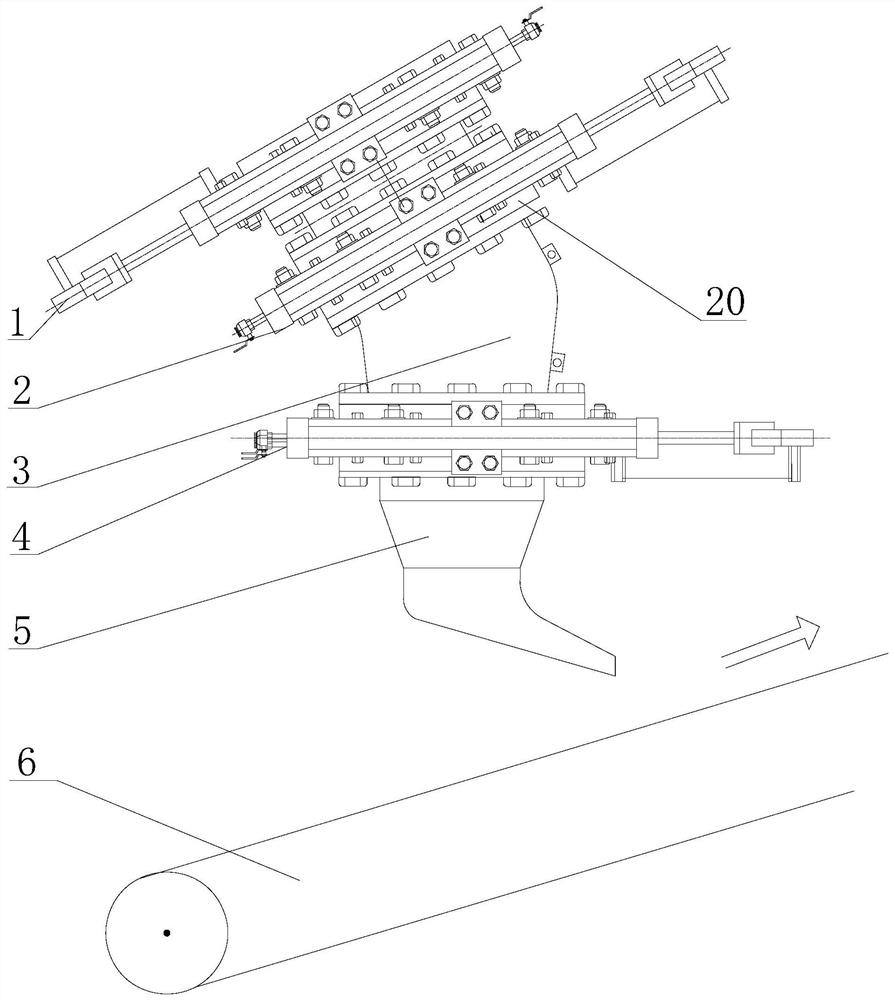

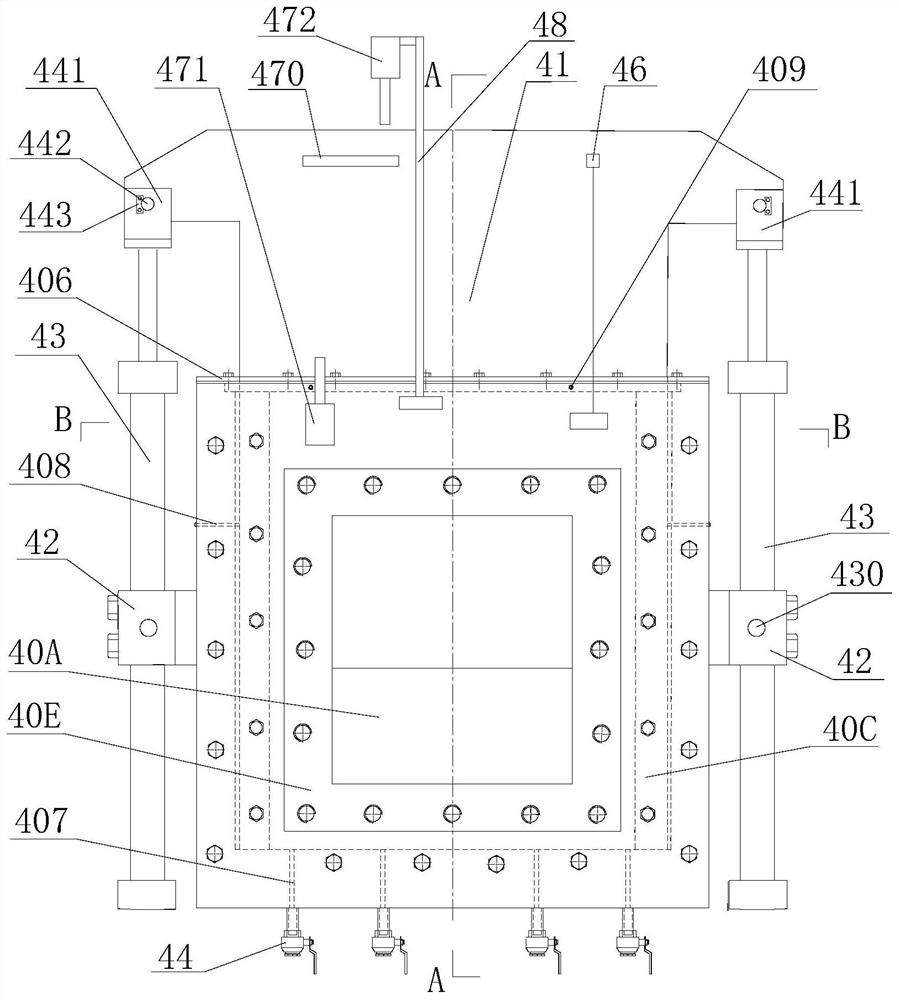

[0039] see Figure 1 to Figure 4 , the slag discharge gate system of the screw conveyor of the earth pressure balance shield machine of the present invention includes a first gate 1, a second gate 2, a slag discharge conduit 3, a Three gates 4 and slag hopper 5.

[0040] The structure and size of the first gate 1, the second gate 2 and the third gate 4 are the same; and the opening direction of the first gate 1 is opposite to the rotation direction of the belt conveyor 6, and the second gate 2 The opening direction of the gate is the same as the direction of rotation of the belt conveyor 6, and the opening direction of the third gate 4 is the same as that of the second gate 2.

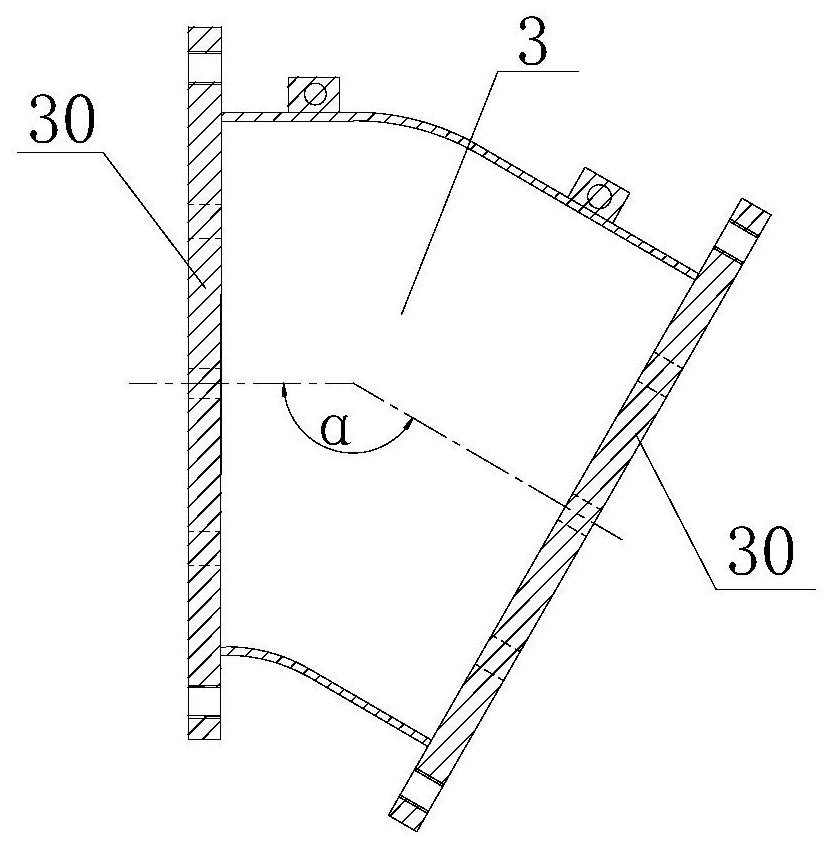

[0041] The slag discharge conduit 3 is arc-shaped and the angle α between the inlet end and the outlet end is 120°-160°; the inlet end and the outlet end of the slag discharge conduit 3 are also p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com