Piezoelectric sensor pre-tightening device

A piezoelectric sensor and force block technology, which is applied in the application field of piezoelectric quartz sensors in the field of three-dimensional force measurement, can solve the problems that limit the precision and accuracy of piezoelectric force measurement structures, the single direction of preloading force, and the force measurement structure. complex problems, to achieve the effect of simple structure, easy adjustment, and enlargement of the measurement area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

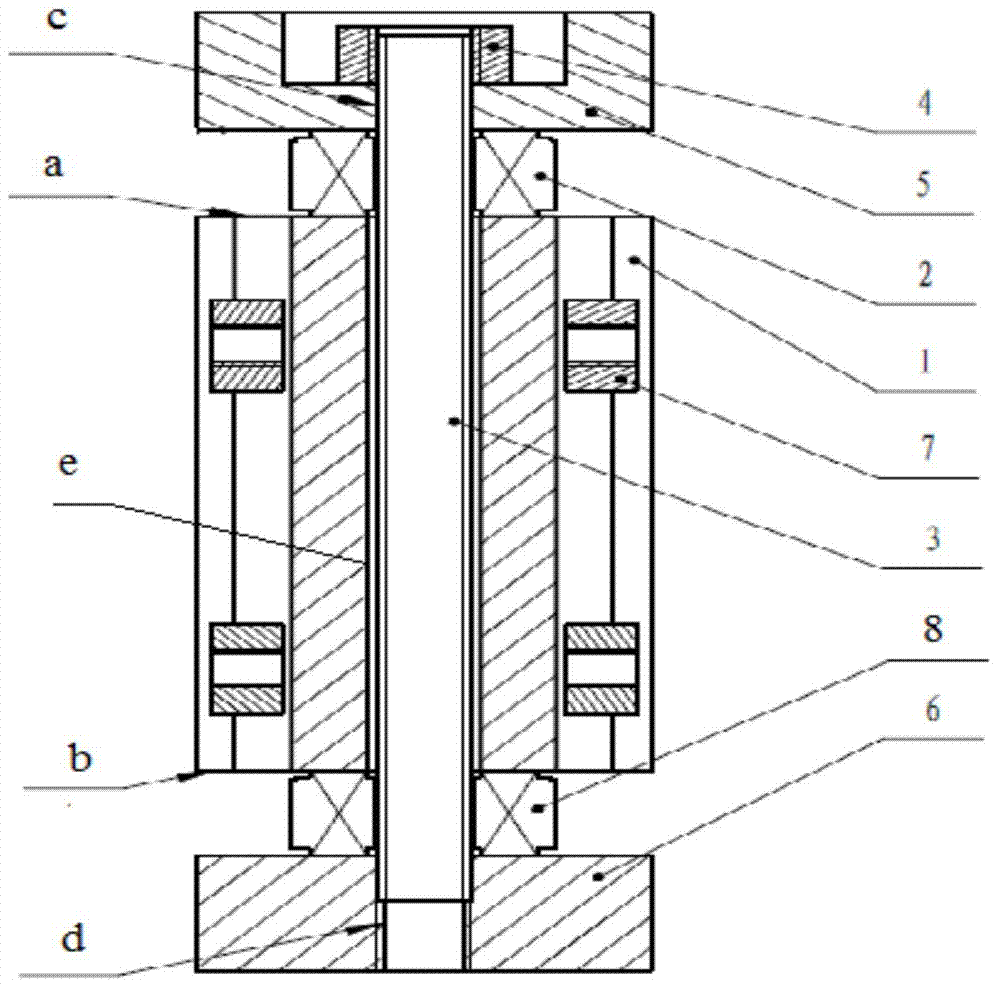

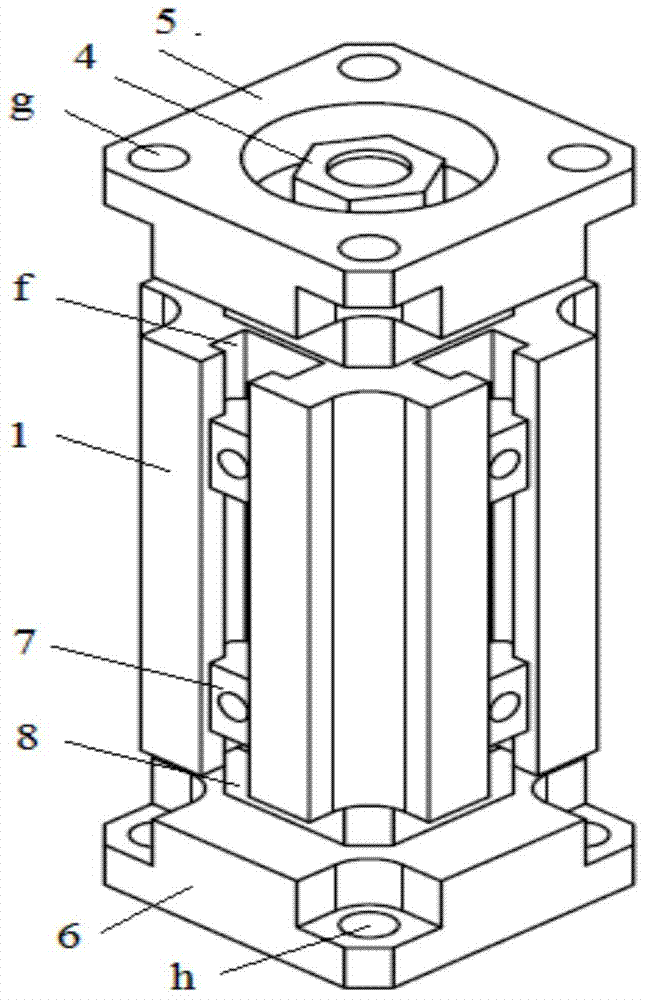

[0011] In the existing method of applying preload to the piezoelectric quartz sensor, since the preload always has a certain rigidity of the elastic body and is connected in parallel with the rigidity of the sensor, a load sharing effect will inevitably occur, that is, the measured external force cannot be 100% The ground is transmitted to the sensor, which affects the accuracy of the measurement. This embodiment adopts as figure 1 , 2 In the shown structure, the upper and lower three-directional piezoelectric sensors 2, 8 all have a central hole. During installation, first screw the lower part of the stud 3 into the threaded hole d of the lower press block 6, and then install the lower three-way force sensor 8 so that the stud 3 passes through the center hole of the lower three-way force sensor 8 , ensure tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com