Cutterhead reduced scale test table of full face rock tunnel boring machine and design method

A design method and test bench technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as large differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

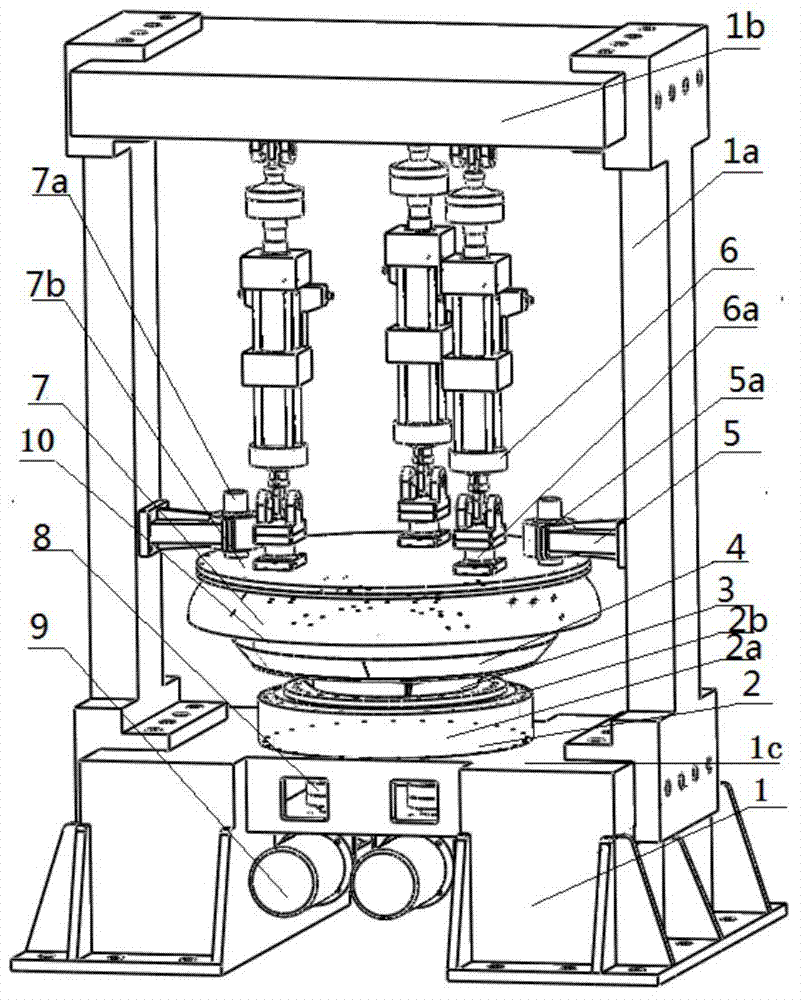

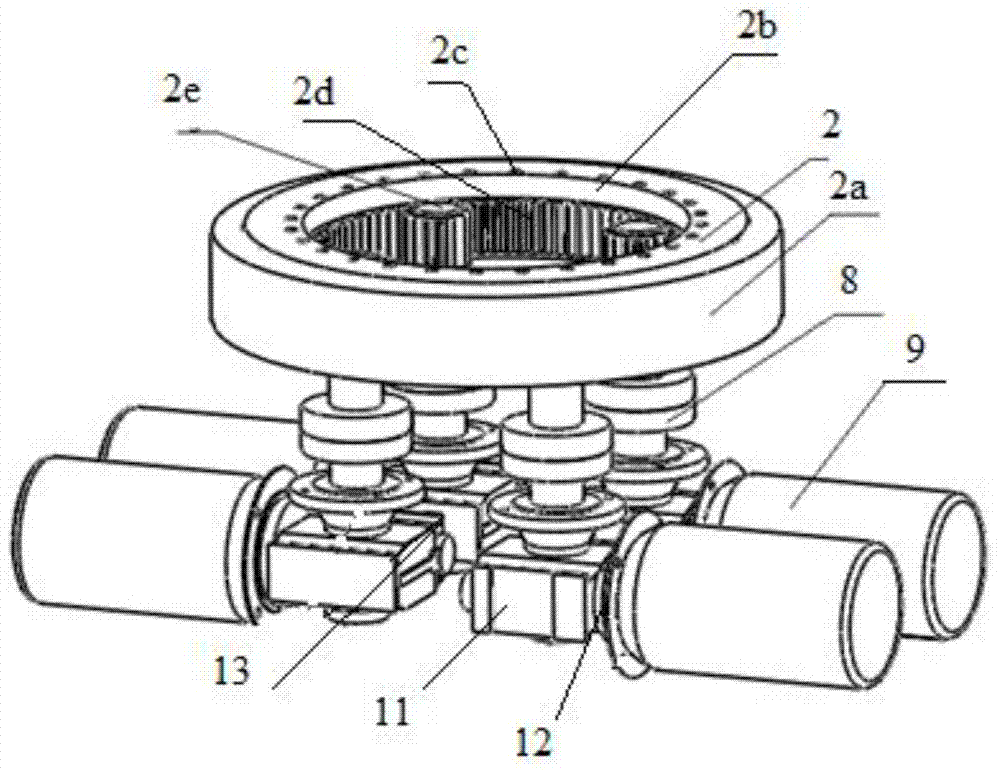

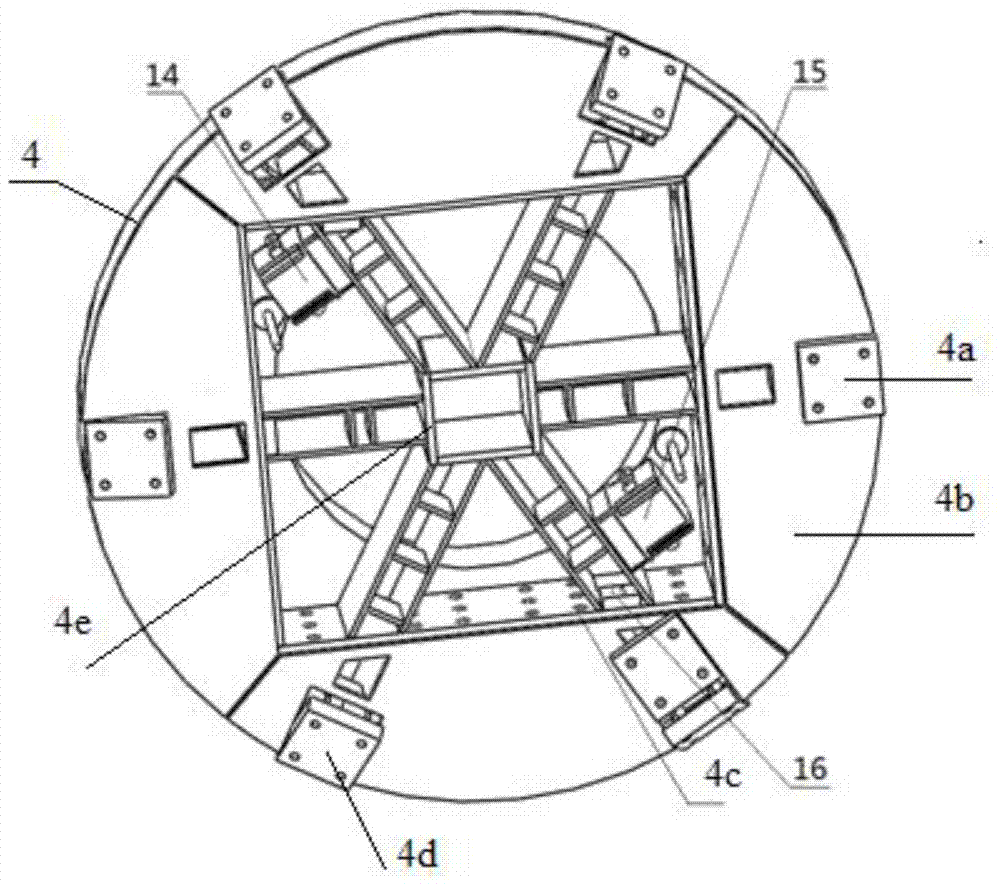

[0020] The actual full-face rock boring machine cutter head is often very large in diameter, and it is neither economical nor possible to conduct experiments with real objects. Therefore, a reduced-scale model can be designed according to the present invention, and experiments can be carried out using the model under the premise of ensuring that the dynamic characteristics and external load of the cutterhead are similar to the real thing. Then the experimental results are inverted according to the proportional relationship of the physical quantities to obtain the corresponding result values under the physical conditions. The design method of this full-section rock tunneling machine cutterhead scaled-scale test bench is to first obtain the proportional relationship between the actual tunneling machine cutterhead and the test bench cutterhead. The physi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com