Microcomputer intelligent liquid fuel controller

An intelligent controller, liquid fuel technology, applied in program control, computer control, general control system, etc., can solve the problems that the size of the fuel control flow is difficult to achieve the desired effect, the heat utilization rate is low, and the fuel consumption of the cooker is high, so as to achieve accurate control. , high sensitivity and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

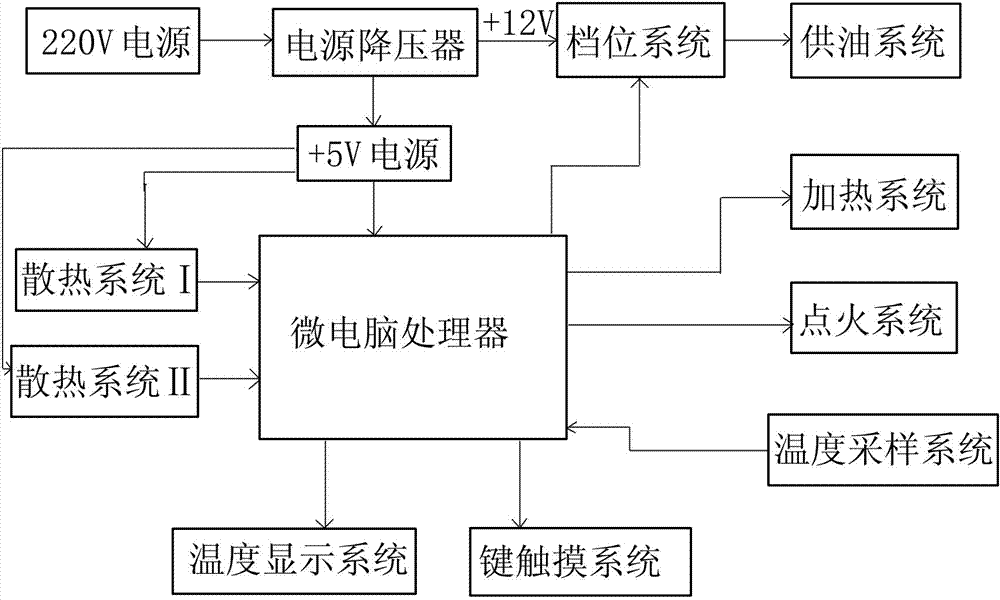

[0011] exist figure 1 Among them, the present invention provides a microcomputer liquid fuel intelligent controller, which includes a 220V power supply and a controller body, the controller body is provided with a housing, and a microcomputer processor, gear system, oil supply system, heating system, ignition system, temperature sampling system and temperature display system, the output end of the 220V power supply is connected with a power step-down device, and the output port I and output port II of the power step-down device are connected to the power end of the gear system and the microcomputer processor respectively. The power supply terminal is connected, the 220V power supply is reduced to 12V power supply and 5V power supply through the power step-down device, the 12V power supply is output to the power supply terminal of the gear system through the output terminal Ⅰ of the power supply step-down device, and the 5V power supply is passed through the output terminal II ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com