Crystalline silicon solar cell having doped silicon carbide layer and manufacturing method thereof

A solar cell, silicon carbide layer technology, applied in the field of solar cells, can solve problems such as excessive photon energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

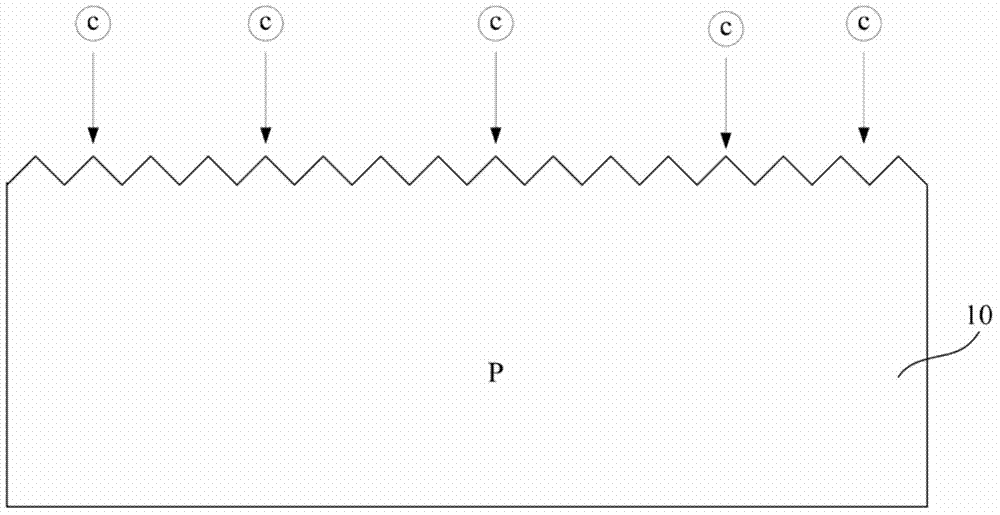

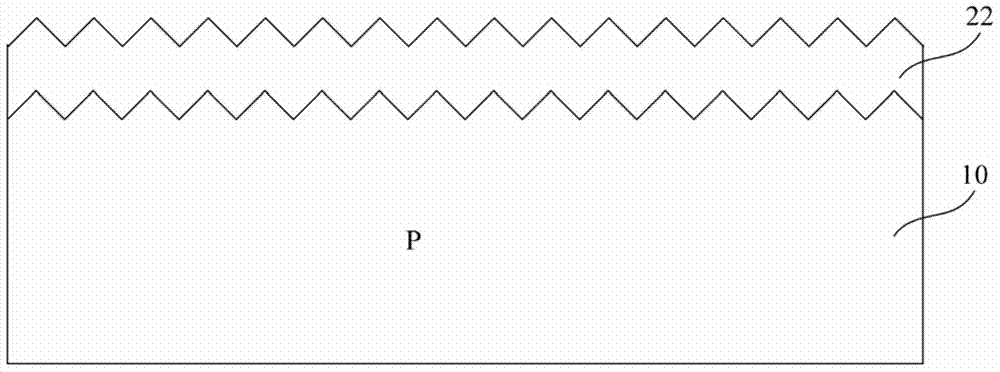

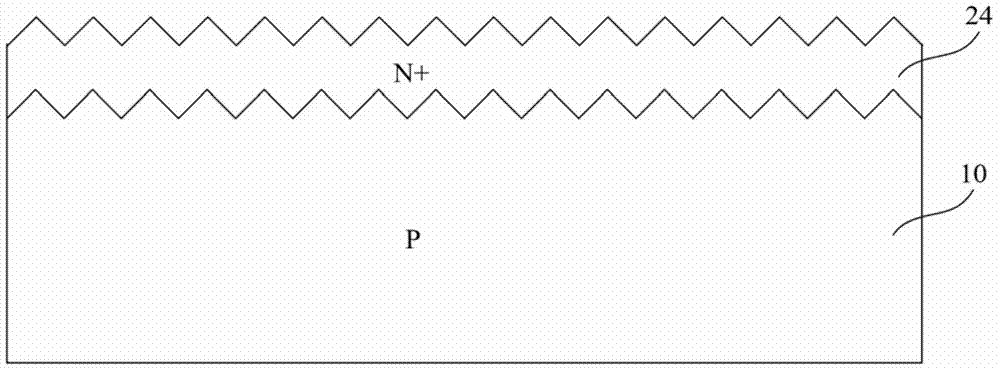

[0027] Please refer to Figure 1A to Figure 1C , which is a schematic diagram of the manufacturing steps of the doped silicon carbide layer of the crystalline silicon solar cell with the doped silicon carbide layer of the present invention. First, a semiconductor substrate 10 with a roughened surface is provided, and carbon elements (carbon elements are represented by C in the figure) are implanted into the first surface of the semiconductor substrate 10 by ion implantation, and then the silicon carbide layer 22 is formed by high temperature annealing. ,Such as Figure 1A , Figure 1B shown. By controlling the amount of energy provided by the carbon element, the depth of the carbon element implanted into the semiconductor substrate is controlled. For example, the implantation depth of the carbon element can be controlled to be less than 2 micrometers (μm), that is, the depth of the silicon carbide layer is 2 μm. Next, the silicon carbide layer 22 is reversely doped with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com