Method for manufacturing vertical type high-power gallium nitride PIN diode

A PIN diode and gallium nitride technology, which is applied in the field of manufacturing vertical high-power gallium nitride PIN diodes, can solve the problems of large chip area, affecting the DC and switching characteristics of components, and not being successfully introduced into the high-power market. The effect of low sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

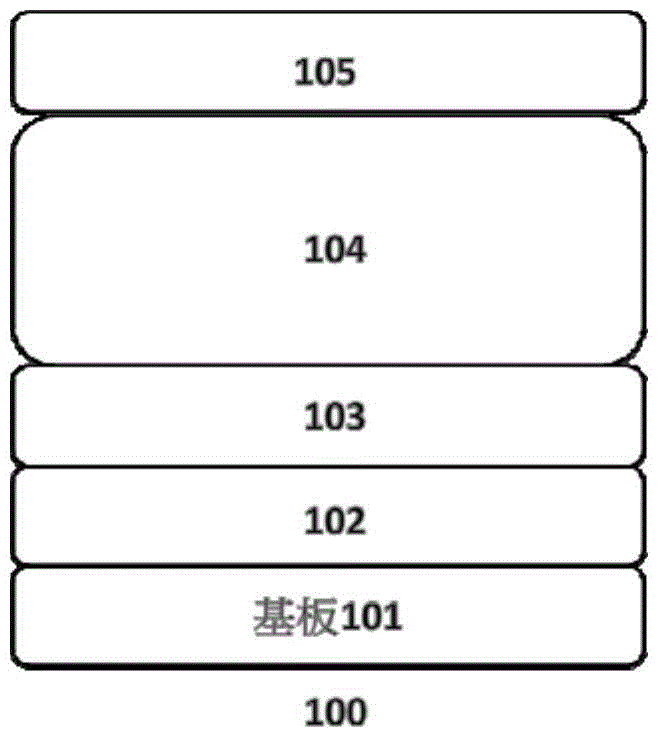

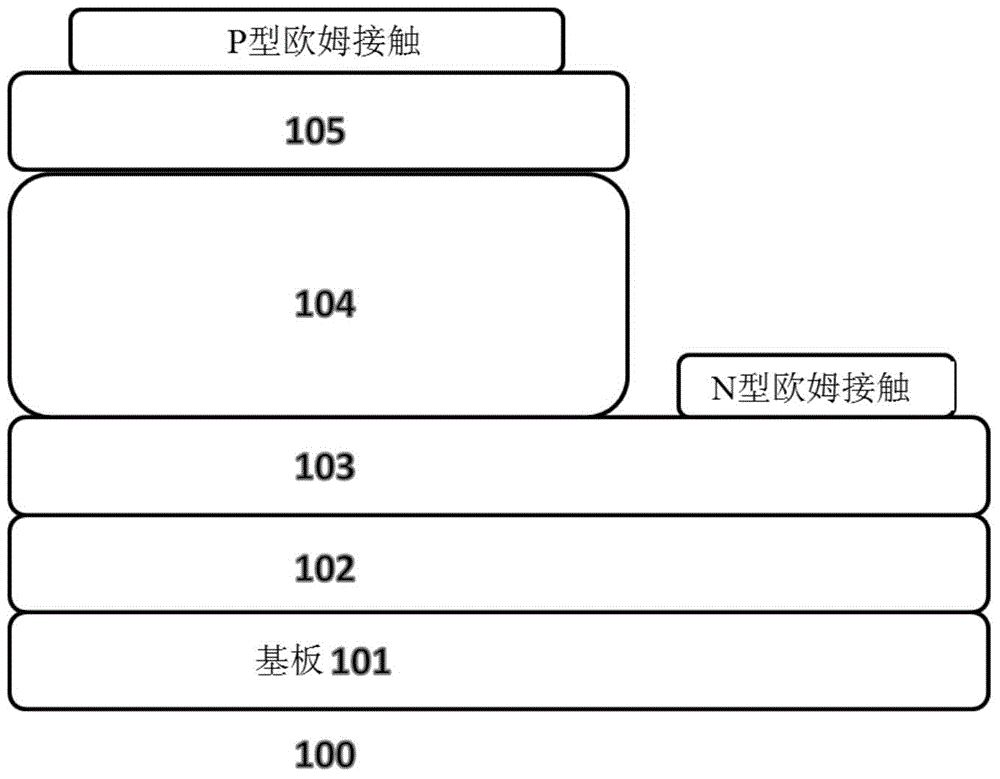

[0035] Such as figure 1 As shown, firstly, a substrate 101 is provided, and the substrate 101 is not particularly limited, and may be commonly used and well-known such as silicon (Si), gallium arsenide (GaAs), sapphire, SiC, and the like. In addition, multiple layers of material layers not shown and serving as various active / passive elements may have been formed on the substrate. Then as figure 1 As shown, a gallium nitride semiconductor stack 102 is formed on the substrate 101 as a buffer layer, and then, the gallium nitride semiconductor stack 102 is grown with a high concentration (1×10 19 cm -3 ) gallium nitride semiconductor layer 103; after that, grow a low concentration (1x10 16 cm -3 ) gallium nitride semiconductor layer 104 (8um), the final high concentration (1x10 18 cm -3 ) GaN semiconductor layer 105 to complete the device structure.

[0036] It can expose the multiple layers of material layers through well-known necessary processes such as photolithography ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com