Hydraulic mounted plough

A technology of hydraulic suspension and ploughshares, which is applied to ploughs, agricultural machinery, and lifting devices of agricultural machinery, etc., can solve the problems of poor adaptability to the degree of soil softness and hardness, time-consuming and laborious, broken ploughshares, etc., and achieves consistent ridge depth, strong flexibility, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

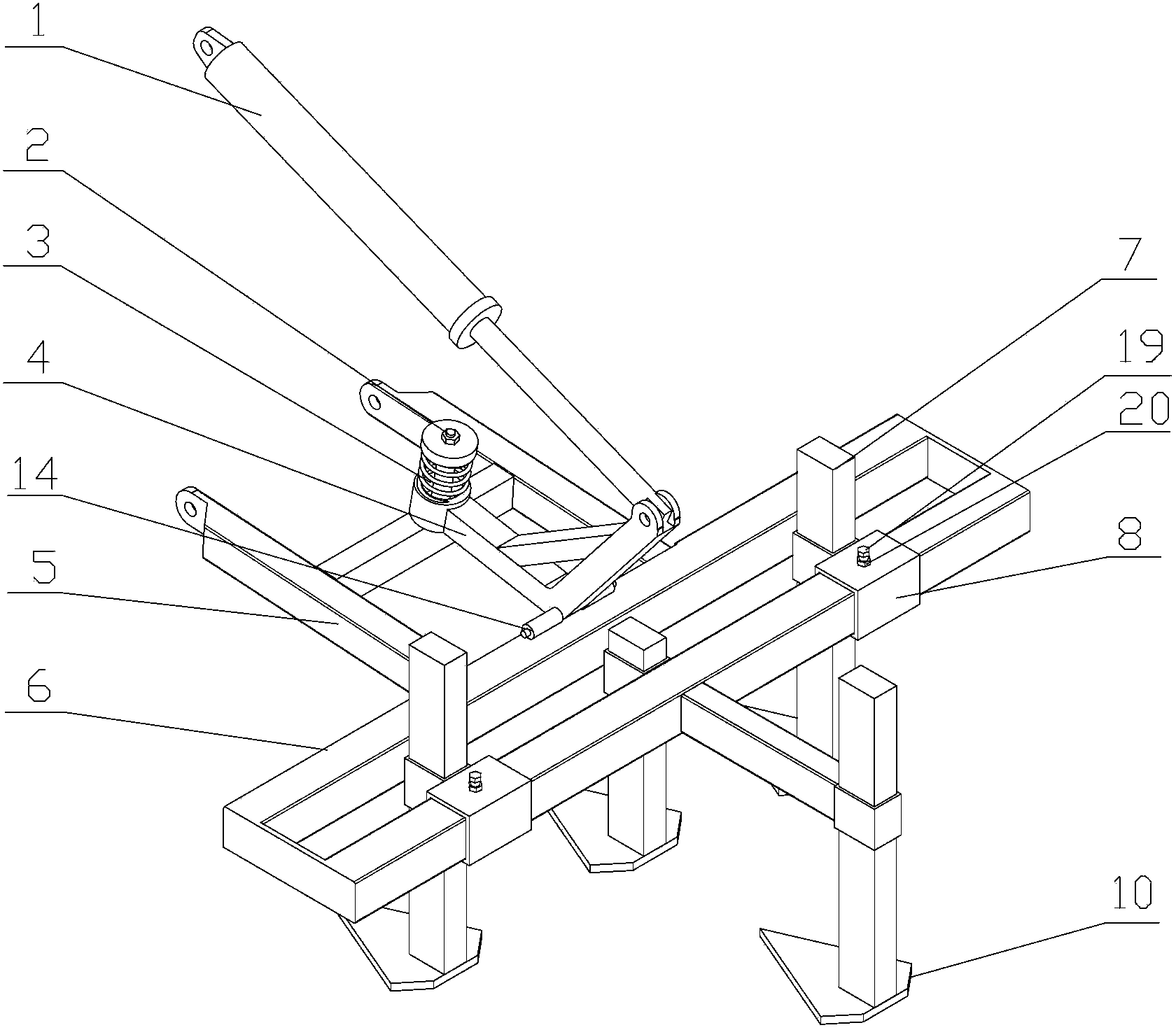

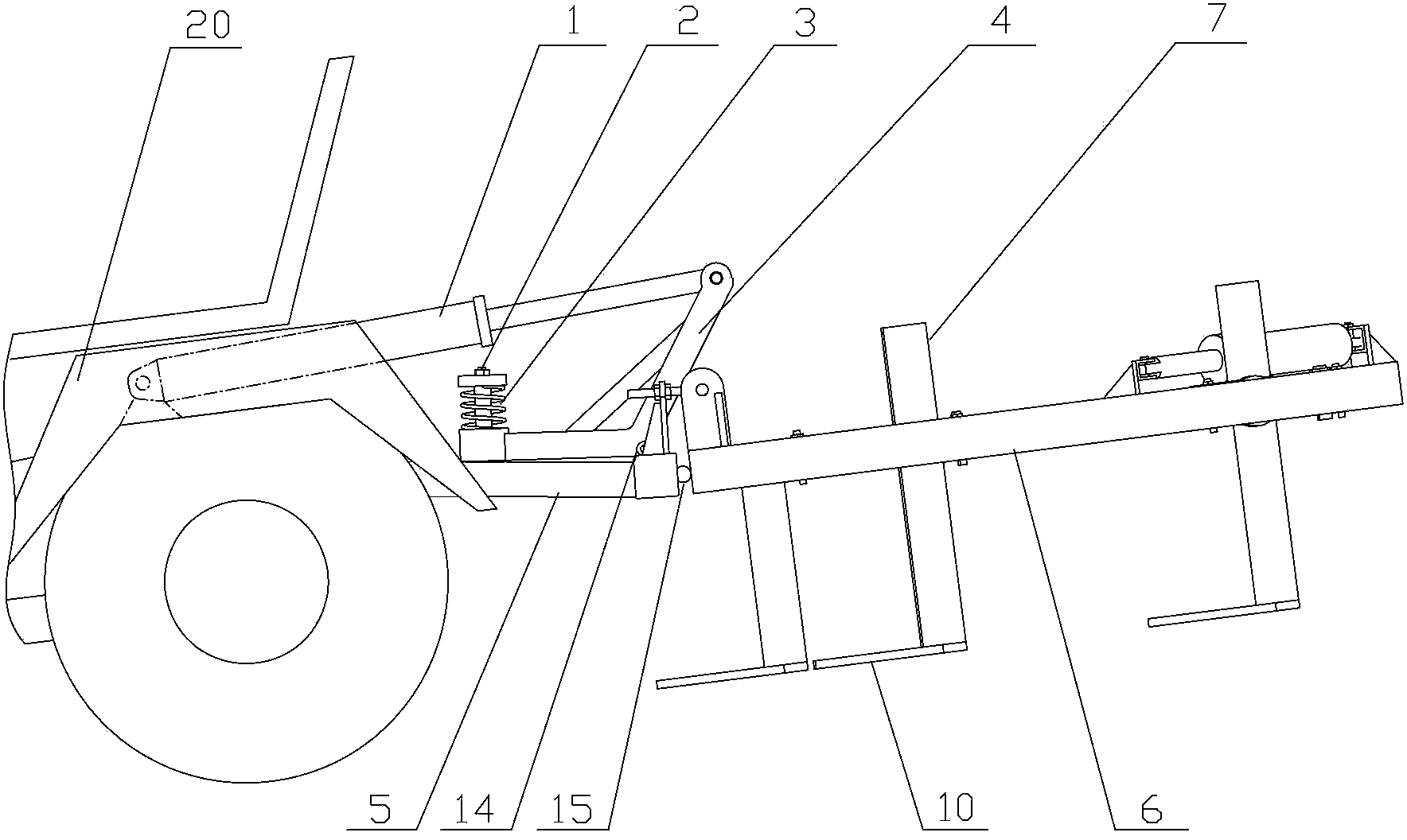

[0027] Such as figure 1 As shown, the present invention includes a lifting oil cylinder 1, an automatic lifting device 4, a traction support 5, a plowshare support 6 and a plowshare device, wherein the front end of the traction support 5 is hinged with the rear of the motor vehicle, and the rear end is connected with the plowshare support 6. The automatic lifting The device 4 is hinged on the traction bracket 5 , and one end is hinged to the output end of the lifting cylinder 1 . There are multiple plowshare devices installed on the plowshare bracket 6 . The lifting cylinder 1 is a two-way hydraulic cylinder, and is connected with a single-column hydraulic distributor through a hydraulic oil pipe. The traction support 5, the plowshare support 6 and the plowshare device are driven by the lifting cylinder 1 to rise or fall as a whole.

[0028] The automatic lifting device 4 comprises a V-shaped support, a screw rod 2, a spring 3, a limit block and a stop nut, wherein the screw ...

Embodiment 2

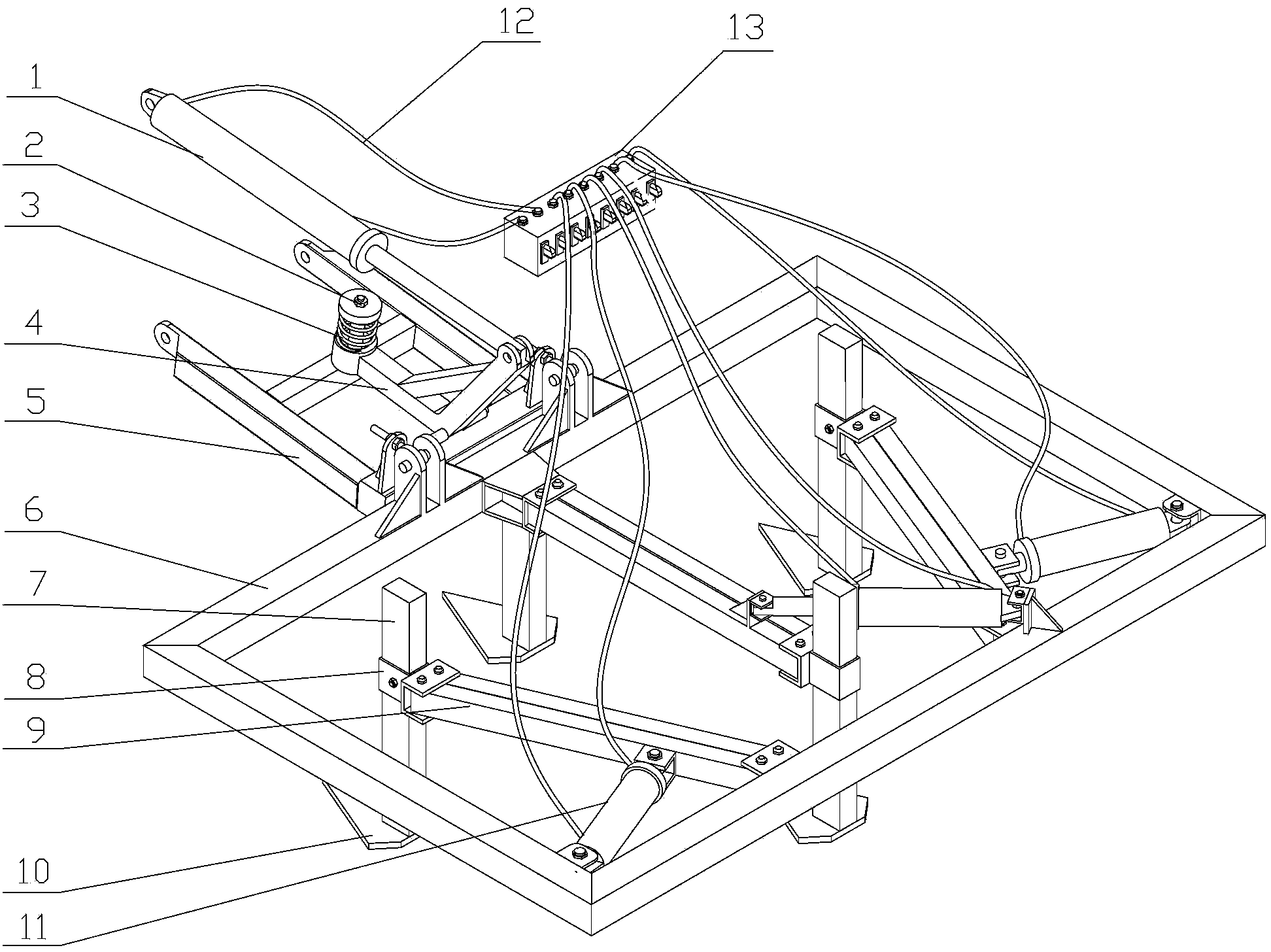

[0033] Such as Figure 2-5 As shown, the automatic lifting device 4 and the plowshare device of the present embodiment are the same as those of the first embodiment. The difference is that in this embodiment, the distance between the plowshares 10 is adjusted by the plowshare spacing adjustment mechanism, and a plowshare parallelism adjustment mechanism is provided between the traction bracket 5 and the plowshare support 6, which is used to adjust the parallelism between the plowshare support 6 and the ground , so that the heights of each plowshare 10 are equal, thereby ensuring that the plowing depth of each plowshare 10 is the same.

[0034] The plowshare spacing adjustment mechanism includes an adjustment arm 9 and an arm adjustment oil cylinder 11 . The plowshare device is hinged on the plowshare support 6 through the adjustment arm 9, the adjustment support arm 9 is hinged with the output end of the arm adjustment cylinder 11 installed on the plowshare support 6, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com