Water washing type automatic cleaning filter

An automatic cleaning and filter technology, which is applied to fixed filter element filters, gravity filters, filtration separation, etc., can solve problems such as ecological environmental hazards, incompatibility with energy saving and environmental protection and low-carbon development requirements, and affect the normal operation of the water cycle. , to achieve the effect of controlling production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

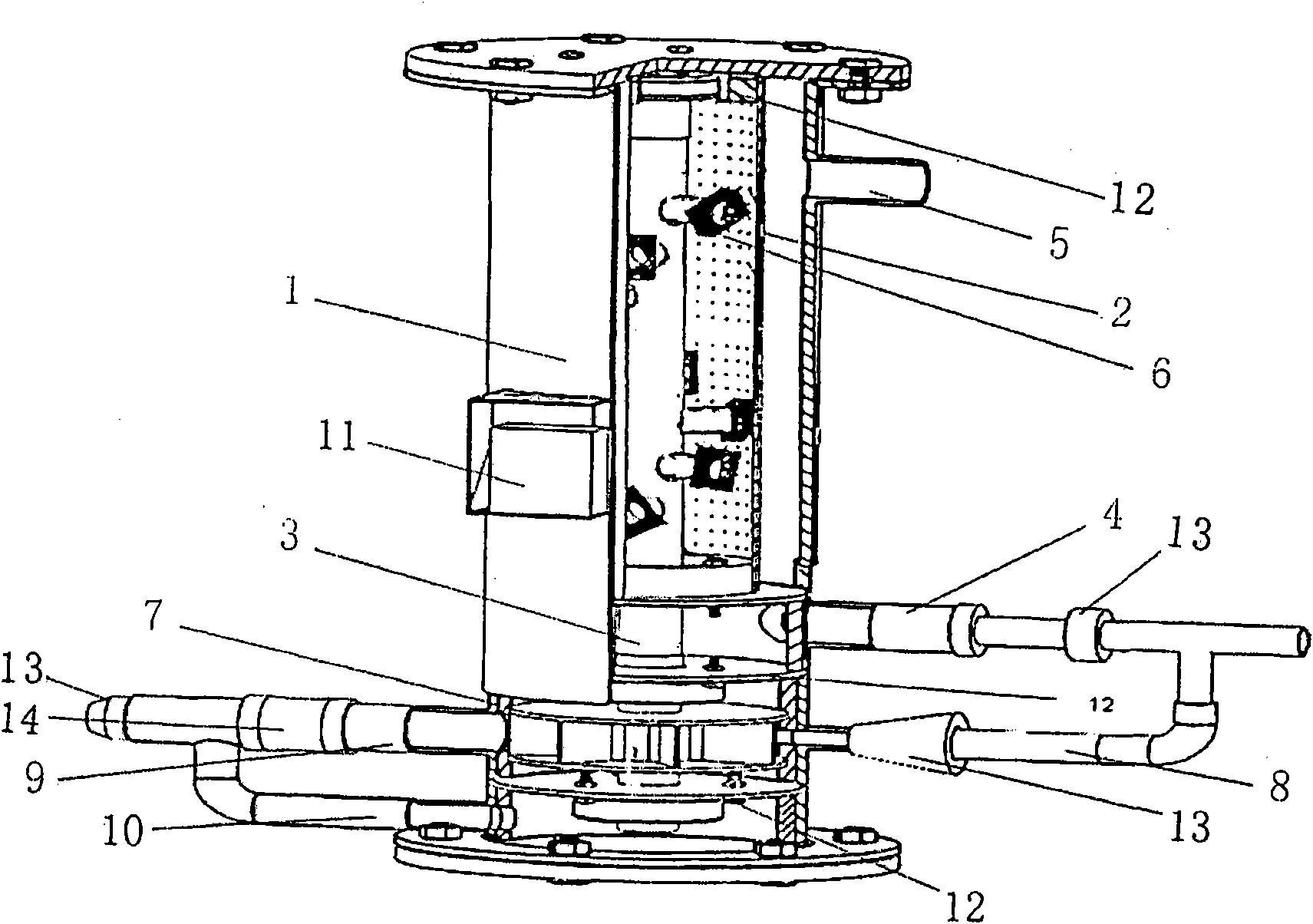

[0013] figure 1 As shown: a filter cylinder 2 is installed in an outer cylinder 1 whose two ends are closed by flanges. There is a sewage discharge shaft tube 3 in the middle of the filter screen cylinder 2. Several cleaning brushes are distributed around the sewage discharge shaft tube 3. The sewage suction pipe 6, the inner end of the sewage shaft pipe 3 in the outer cylinder 1 is connected with a driving impeller 7, the outer cylinder 1 is provided with a driving water inlet pipe 8 for flushing to the driving impeller 7, and the other side is provided with a driving impeller 7. The water outlet pipe 9, the circulating water inlet pipe 4 on the side of the outer cylinder 1 communicates with the inside of the filter cylinder 2, the end of the sewage shaft pipe 3 is provided with a sewage discharge pipe 10 connected to the driving outlet pipe 9, and the side of the outer cylinder 1 is provided with a circulation Outlet pipe 5. The two ends of the sewage shaft tube 3 are insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com