Electroplating sludge treatment method and device

A treatment method and technology for electroplating sludge, applied in chemical instruments and methods, phosphorus oxyacid, solid separation, etc., can solve the problems of low energy consumption, electroplating sludge pollution, short process flow, etc., and achieve low energy consumption, Solve the effect of descaling and effective separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

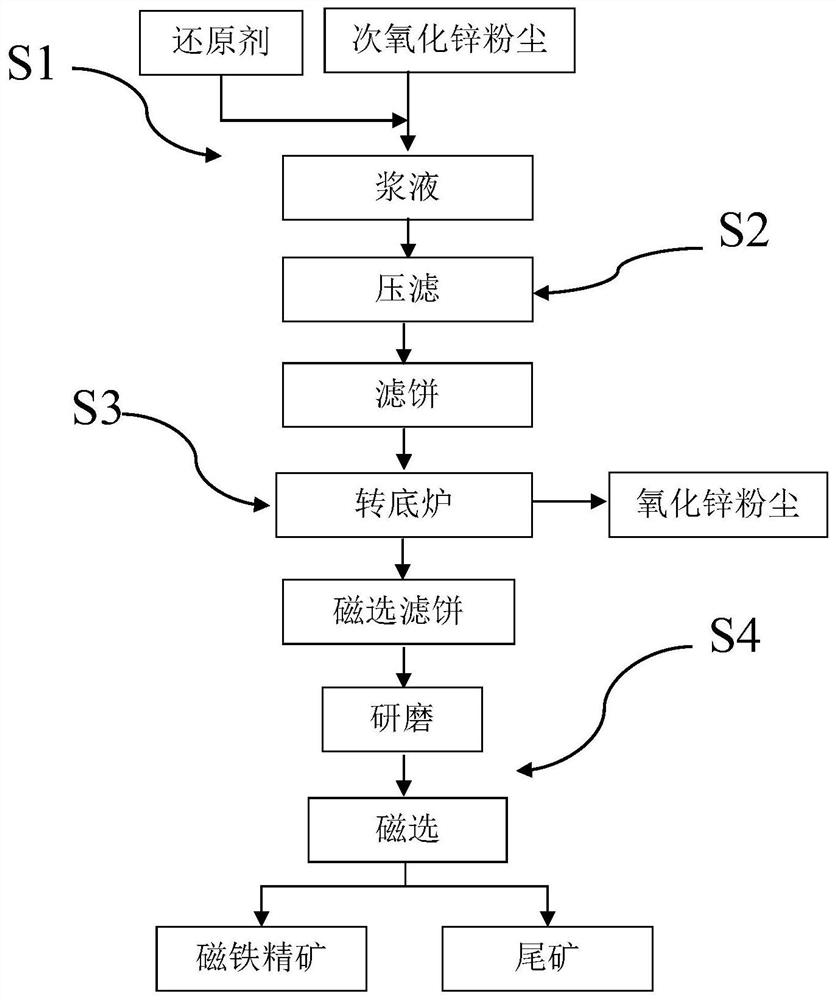

[0067] The electroplating sludge with a TFe content of 32.98%, a Zn content of 3%, a P content of 3.8%, and a water content of 53% and the reducing agent semi-coke were fully stirred in the slurry tank according to the ratio of 100:28 to obtain a slurry, semi-coke The particle size is 0.074mm-0.1mm, and the fixed carbon accounts for 80-85% of the total mass of semi-coke;

[0068] The slurry is filtered through a filter press to obtain a filter cake with a water content of 15.22%;

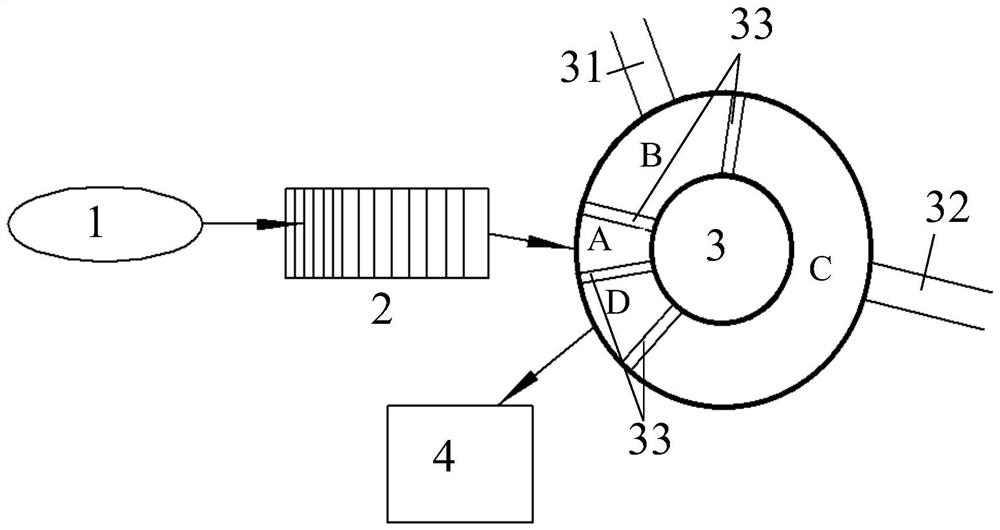

[0069] The filter cake enters the rotary hearth furnace through the feeding system, passes through the water volatilization area and the reduction magnetic selection area in turn, and after being discharged from the cooling discharge area, the magnetic separation filter cake and zinc oxide dust are obtained; the time for one revolution of the rotary hearth furnace is 55min, the filter cake stays in the feed zone for 1min; stays in the moisture volatilization zone for 10min, the O in the moisture vol...

Embodiment 2

[0073] The electroplating sludge with a TFe content of 31.56%, a Zn content of 3.6%, a P content of 4.2%, and a water content of 55.18% and the reducing agent semi-coke were fully stirred in the slurry tank according to the ratio of 100:30 to obtain a slurry, semi-coke The particle size is 0.074mm-0.1mm, and the fixed carbon accounts for 80-85% of the total mass of semi-coke;

[0074] The slurry is filtered through a filter press to obtain a filter cake with a water content of 13.12%;

[0075] The filter cake enters the rotary hearth furnace through the feeding system, passes through the water volatilization area and the reduction magnetic selection area in turn, and after being discharged from the cooling discharge area, the magnetic separation filter cake and zinc oxide dust are obtained; the time for one revolution of the rotary hearth furnace is 60min, the filter cake stays in the feed zone for 1min; stays in the moisture volatilization zone for 10min, the O 2 The concent...

Embodiment 3

[0079] The electroplating sludge with a TFe content of 33.55%, a Zn content of 3.7%, a P content of 5.23%, and a water content of 57.34% and the reducing agent semi-coke were fully stirred in the slurry tank according to the ratio of 100:30 to obtain a slurry, semi-coke The particle size is 0.074mm-0.1mm, and the fixed carbon accounts for 80-85% of the total mass of semi-coke;

[0080] The slurry is filtered through a filter press to obtain a filter cake with a water content of 15.22%;

[0081] The filter cake enters the rotary hearth furnace through the feeding system, passes through the water volatilization area and the reduction magnetic selection area in turn, and after being discharged from the cooling discharge area, the magnetic separation filter cake and zinc oxide dust are obtained; the time for one revolution of the rotary hearth furnace is 65min, the filter cake stays in the feed area for 2min; stays in the moisture volatilization zone for 12min, the O in the moistu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| magnetic susceptibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com