Three-phase circulating fluidizing bed evaporator

A circulating fluidized bed and evaporator technology, which is applied in forced circulation evaporators, evaporator accessories, evaporation, etc., can solve the problems of poor heat conduction performance, short service life, high viscosity, etc., to reduce flow rate, solve scale removal, The effect of improving equipment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

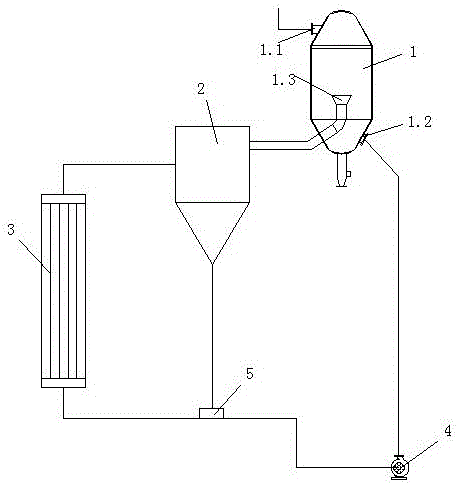

[0008] Example 1: A three-phase circulating fluidized bed evaporator, including a gas-liquid separation chamber 1, a solid-liquid separation device 2, and a heater 3. The top of the gas-liquid separation chamber 1 is provided with a steam outlet 1.1, and a feed liquid outlet 1.2 is provided near the bottom. , the middle part is provided with a feed liquid inlet 1.3, a feed liquid outlet 1.2 is connected to a heater 3 through a conveying pipeline, a circulating pump 4 is arranged on the conveying pipeline, the heater 3 is connected to the inlet of the solid-liquid separation device 2 through a conveying pipeline, and the solid-liquid separation device 2 The liquid outlet is connected to the feed liquid inlet 1.3 of the gas-liquid separation chamber 1 through a pipeline, and the solid recovery device 5 is installed on the delivery pipeline between the circulation pump 4 and the heater 3, and the solid outlet at the bottom of the solid-liquid separation device 2 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com