Emulsified liquid concentration optimization setting method during automotive sheet cold rolling of double-rack four-roller mill

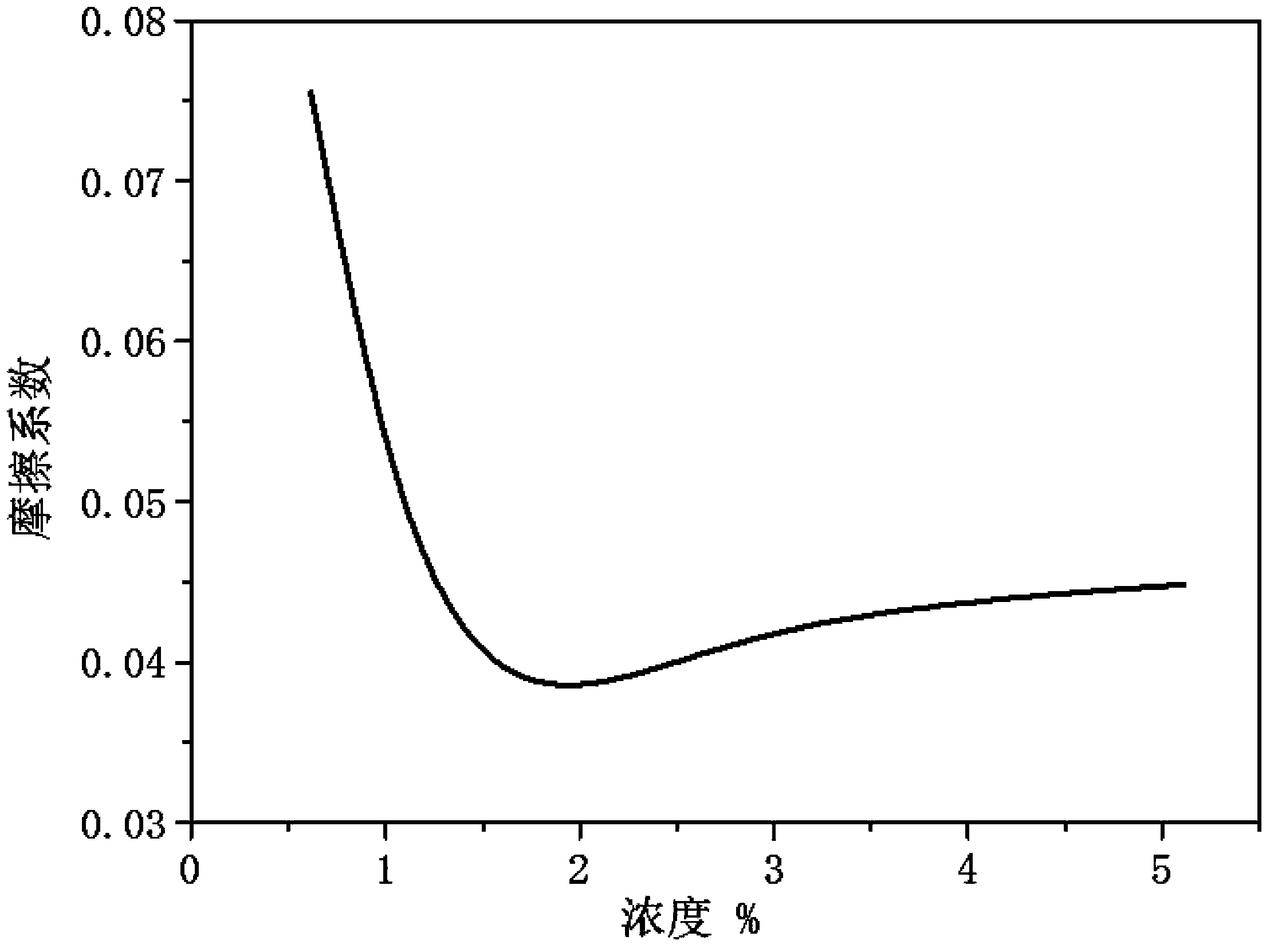

A technology for optimizing settings and automotive plates, applied in the direction of roll speed control, metal rolling, contour control, etc., can solve problems such as friction, high rolling heat, vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

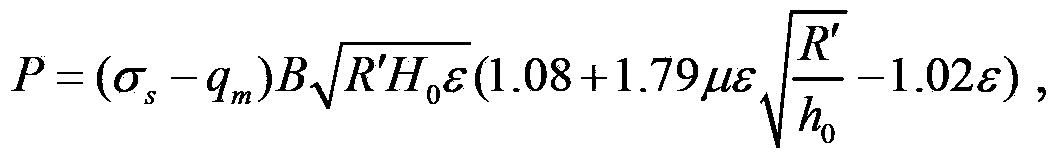

Method used

Image

Examples

no. 1 example

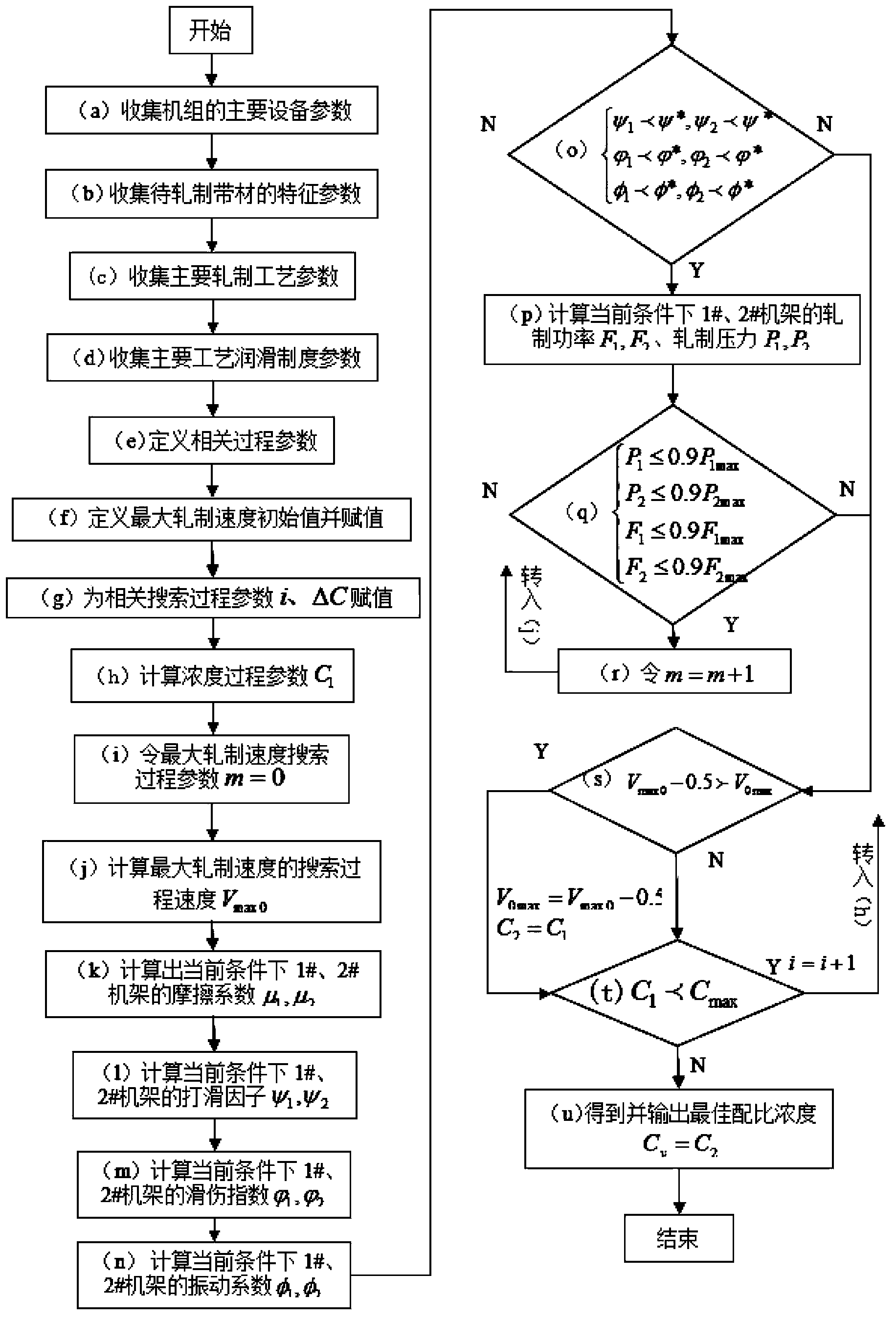

[0051] figure 2 It is a general calculation block diagram for optimal setting of emulsion concentration in the cold rolling process of a high-grade automobile plate in a double-stand four-high rolling mill according to the present invention. Taking a certain double-stand 1420 rolling mill as an example, with the help of figure 2 To describe the optimization setting process of high-grade automotive sheet emulsion concentration with specific specifications.

[0052] First, in step 1, the main equipment parameters of the two-stand four-high rolling mill to be optimized are collected, mainly including the working roll diameters of 1# and 2# stands Maximum rolling pressure P of 1# and 2# rack mills 1max =1800t,P 2max =1800t, 1# and 2# stand rolling mill maximum rolling power F 1max =4000Kw, F 2max =4000Kw;

[0053] Subsequently, in step 2, the characteristic parameters of the strip to be rolled are collected, mainly including: the width B=1200mm of the strip; the thickne...

no. 2 example

[0077] In order to further illustrate the implementation process of this patent, taking a certain double-stand 1550 rolling mill as an example, with the help of figure 2 To describe the optimization setting process of high-grade automotive sheet emulsion concentration with specific specifications.

[0078] First, in step 1, the main equipment parameters of the two-stand four-high rolling mill to be optimized are collected, mainly including the working roll diameters of 1# and 2# stands Maximum rolling pressure P of 1# and 2# rack mills 1max =2000t,P 2max =2000t, 1# and 2# stand rolling mill maximum rolling power F 1max =4500Kw, F 2max =4500Kw;

[0079] Subsequently, in step 2, the characteristic parameters of the strip to be rolled are collected, mainly including: the width B=1320mm of the strip; the thickness h of the incoming strip 0 =1.2mm; strip exit thickness h 2 =0.65mm; the modulus of elasticity of the strip E=2.1×10 5 MPa; Poisson's ratio v=0.3 of the strip;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com