Double-spraying-nozzle and multi-colored model printing system

A printing system and double-nozzle technology, applied in the field of double-nozzle multi-color model printing system, can solve the problems of single, cumbersome and complex workpiece body, single color, etc., and achieve the effect of improving pass rate, reducing manufacturing cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

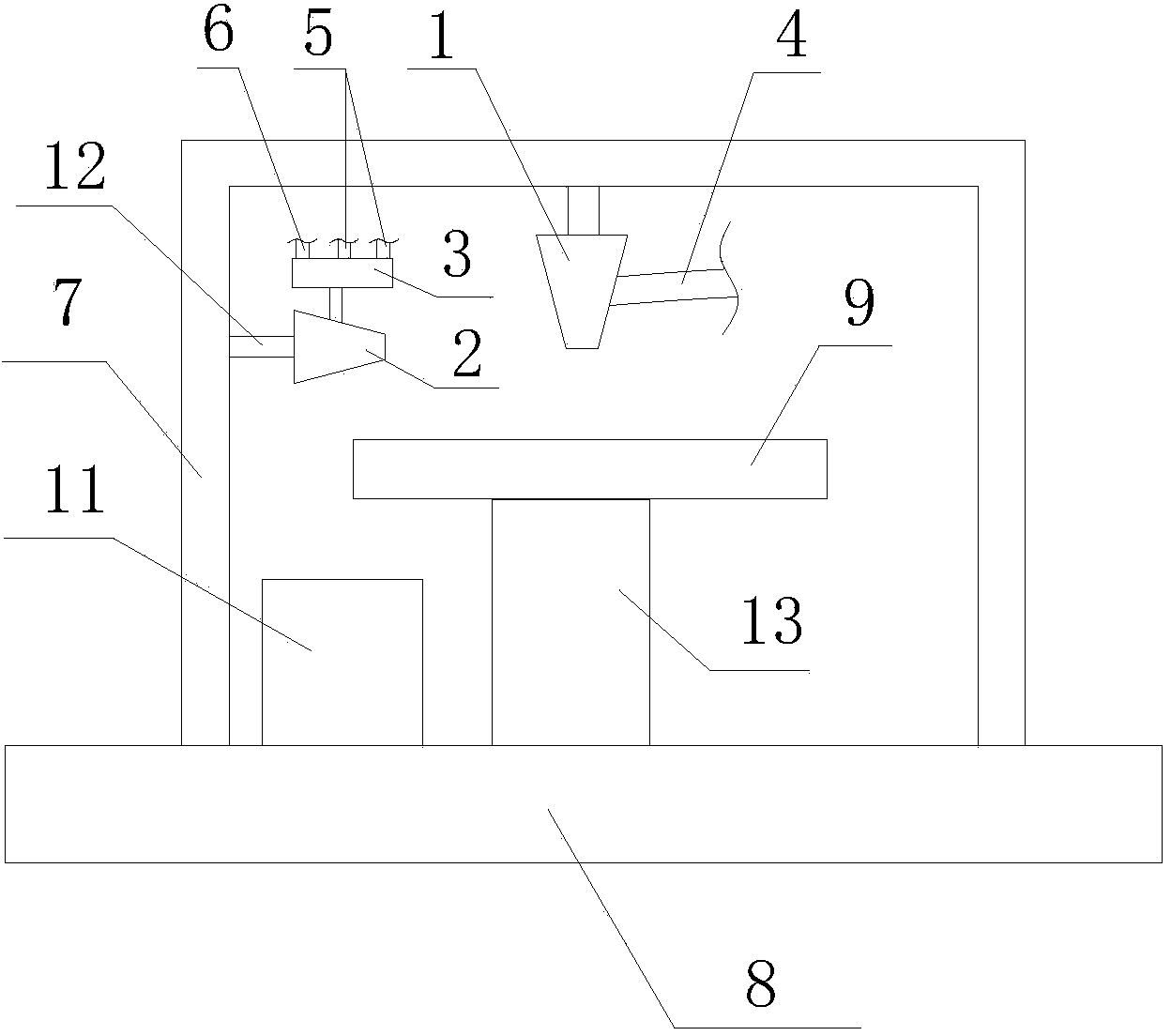

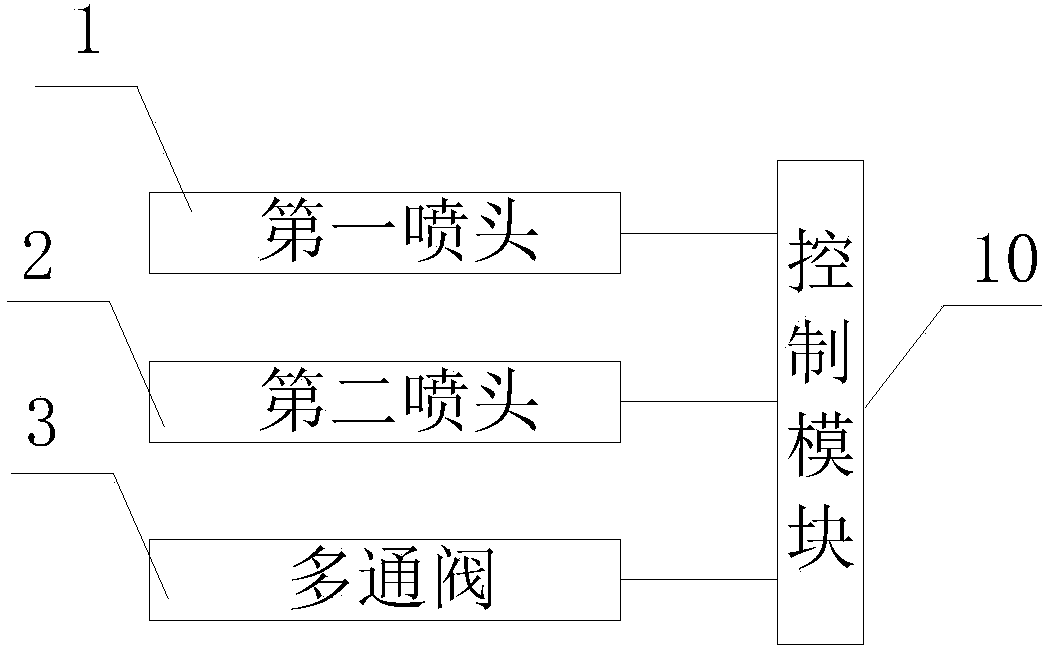

[0021] refer to figure 1 , figure 2 , a dual-nozzle multi-color model printing system proposed by the present invention, comprising: a first nozzle 1, a second nozzle 2, a multi-way valve 3, a base material delivery pipe 4, a plurality of color material delivery pipes 5, a water pipe 6, a support Frame 7, base 8, workbench 9, control module 10 and waste water collection box 11.

[0022] The support frame 7 is installed on the base 8, the first spray head 1 is vertically installed on the support frame 7, the second spray head 2 is horizontally installed on the support frame 7 through the connecting rod 12, and the second spray head 2 can perform hemispherical rotation.

[0023] The first spray head 1 is connected to the base material conveying pipe 4 to extract the base material for printing. The second nozzle 2 is connected to a plurality of color material delivery pipes 5 and water pipes 6 through a multi-way valve 3, and the plurality of color material delivery pipes 5 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com