Three-dimensional engraving machine

A three-dimensional engraving machine and frame technology, applied in the field of machinery, can solve the problems of complex connection and coordination, loose tools, and many parts, etc., and achieve the effects of simple connection and coordination, improved engraving accuracy, and stable state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

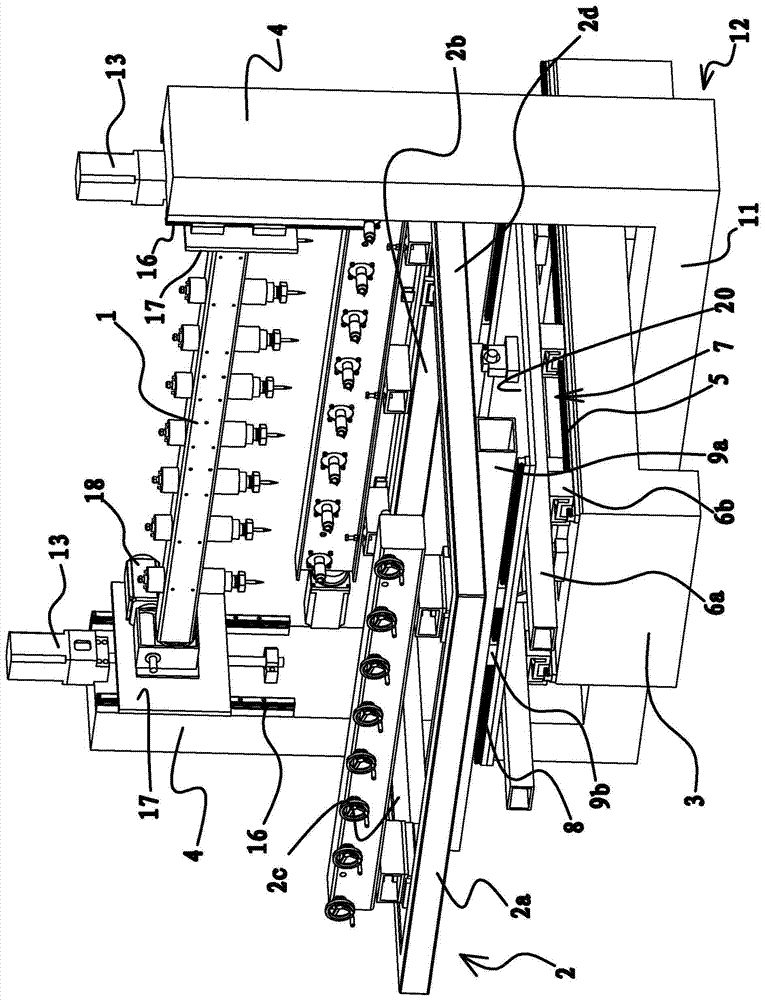

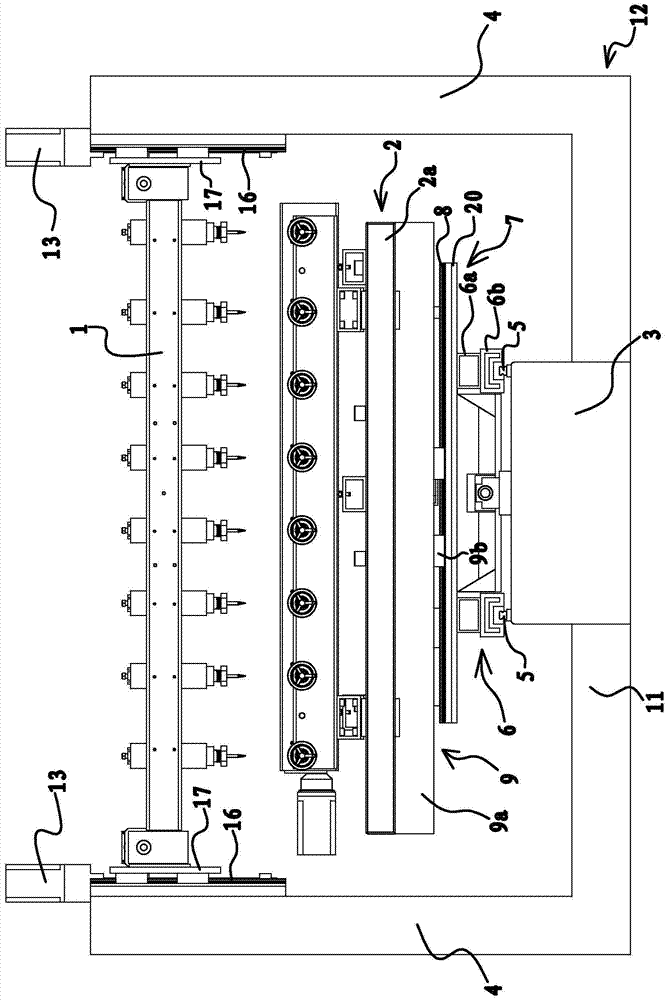

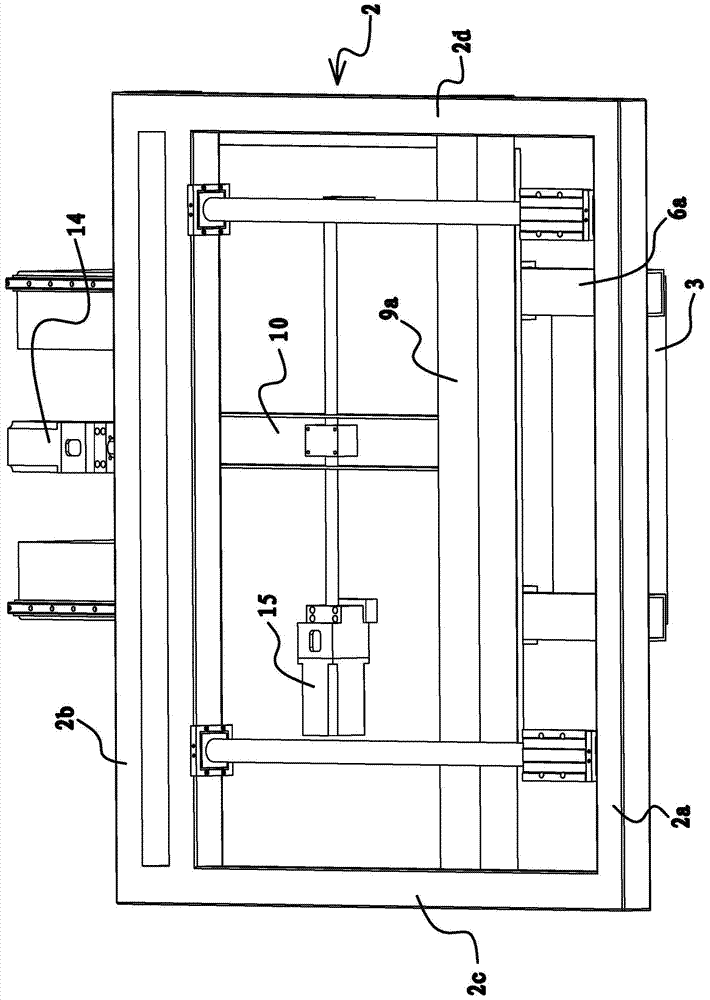

[0033] Such as figure 1 As shown, the three-dimensional engraving machine includes a frame 12 and an engraving platform 2 arranged on the frame 12 . Wherein, the frame 12 includes a base 3 and columns 4 arranged on both sides of the base 3, a bottom beam 11 is provided on the bottom side of the base 3, the base 3 is overlapped on the upper side of the bottom beam 11, and two columns 4 are fixed on the bottom beam 11. ends. A tool holder 1 for installing a tool is provided between the upper ends of the two columns 4 , and a lifting motor 13 for driving the tool holder 1 to move up and down is provided between the column 4 and the tool holder 1 . Specifically, vertical guide rails are fixed on the two columns 4 , and both ends of the tool holder 1 are co-located on the guide rails of the column 4 . The column 4 is provided with a motor, and the motor drives the tool holder 1 to move up and down along the direction of the guide rail on the column 4 through the cooperation of th...

Embodiment 2

[0048] This embodiment is substantially the same as Embodiment 1, the difference is that in this embodiment, if Figure 4 As shown, in order to facilitate the collection and centralized treatment of cutting chips during the engraving process, so that the production environment is more tidy during the engraving process, the bottom of the engraving platform 2 is fixed on the bottom of the engraving platform 2 for receiving cutting chips. Chip board 19.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com