A detachable independent vacuum chamber with in-situ measurement effect

A vacuum cavity and in-situ measurement technology, which is applied in packaging under vacuum/special atmosphere, containers for flexible items, and packaging objects under special gas conditions, can solve the problem of large experimental sites, real-time monitoring of difficult material preparation, Inconvenience and other problems, to achieve multi-possibility, simple annealing treatment, to achieve the effect of space separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the following description, for purposes of explanation, certain details are set forth in order to provide a thorough understanding of the invention. It will be apparent, however, to one skilled in the art that the invention may be practiced with some or all of its features, and that the invention may be practiced without some of the specific details. In other instances, well-known structures and devices are shown in block diagram form in order not to obscure the underlying principles of the invention.

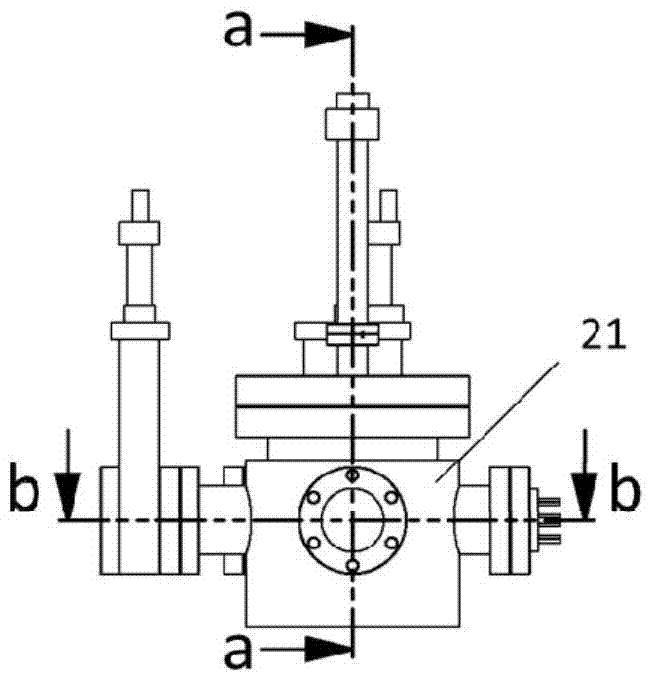

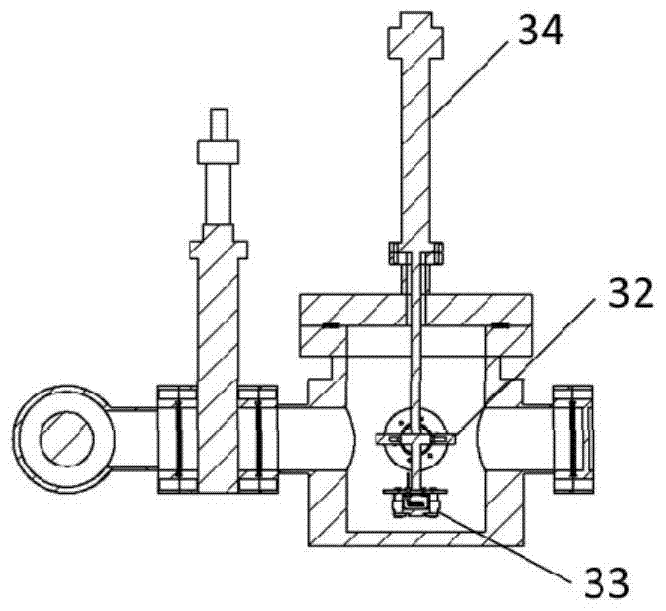

[0026] It should be understood that figure 1 4 is schematic only and may not be drawn to scale.

[0027] The present invention has designed a kind of independent cavity that can transfer sample, below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in detail:

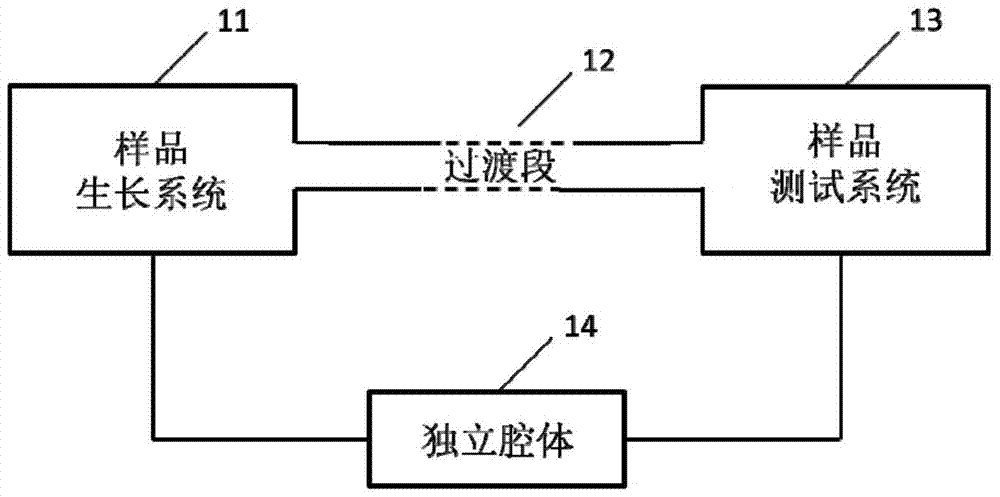

[0028] figure 1 It is the use flowchart of the present invention. Usually, the sample growth system 11 (such as a pulsed laser deposition device) is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com