Weighing method and device of rapid quantitative plate conveyer

A conveyor and plate-type technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of increasing construction difficulty, increasing construction cost and maintenance costs, reducing the bearing capacity of the shaft wall, and achieving cost reduction and simplification. Transport procedure, effect of lowering chamber height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment is a weighing method for a plate type fast quantitative conveyor. The problem to be solved in this embodiment is how to weigh on the slat conveyor. The apron conveyor for material accumulation is different from general material weighing, and has two characteristics: one is that the material is accumulated in a horizontal or near-horizontal strip shape, which makes the weighing process similar to weighing a long rod, but Unlike weighing long rods. The second is that there are dozens of bearing plates that carry the material, and the weight of the material is evenly distributed on each bearing plate. How to weigh this evenly distributed weight can adopt the mode that load cells are installed on all bearing plates. However, there are too many load cells installed in this way, the amount of data processing is too large, and the requirements for digital processing equipment are too high. However, this embodiment proposes a relatively simple method: gather ...

Embodiment 2

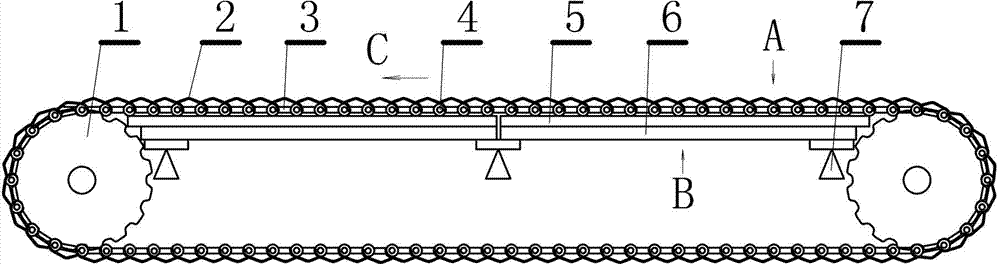

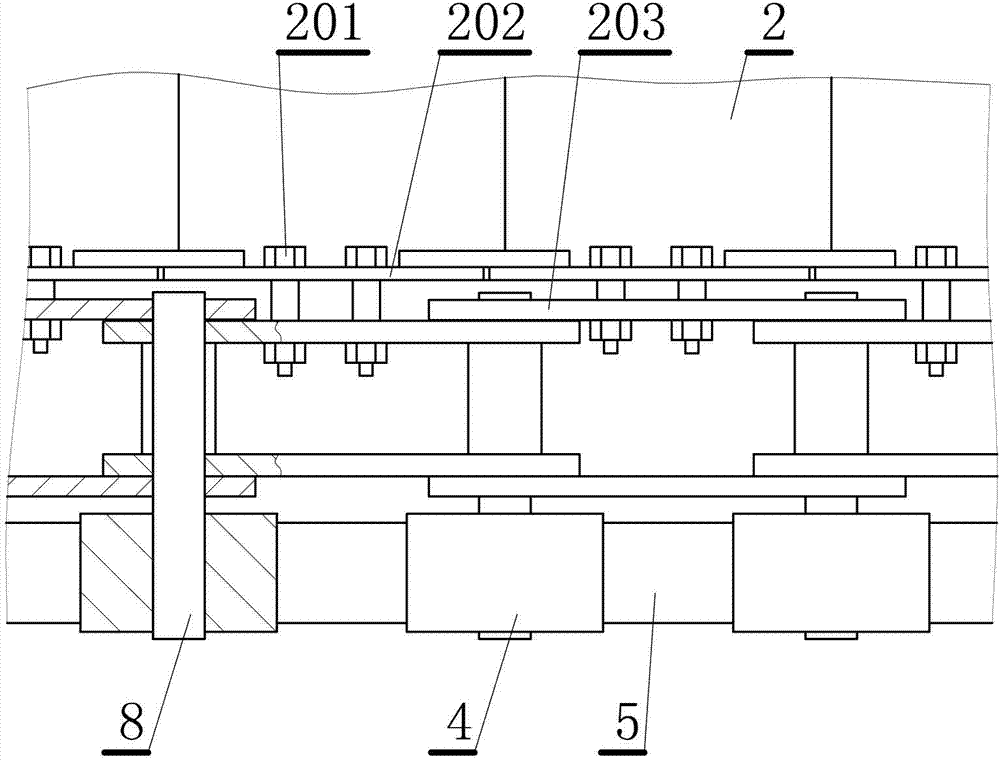

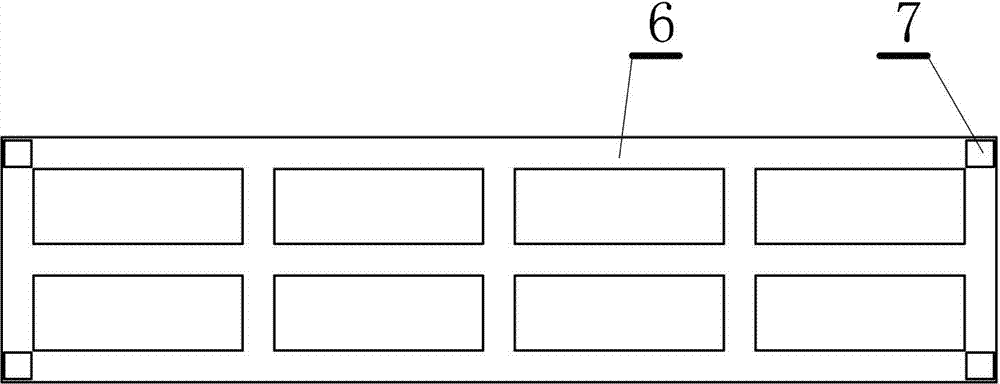

[0033] This embodiment is a device for weighing according to the method described in the embodiment, such as figure 1 , 2 shown. This embodiment includes: the sprocket 1 and the chain 3 of the load-bearing plate 2 installed on the left and right sides of the slat conveyor, each chain link of the chain is provided with a short axis whose rotation axis is perpendicular to the chain movement direction, and the The short shaft 8 is provided with rollers 4, and the rollers on the chains on both sides run on more than one section of guide rails 5 on the left and right sides respectively. Above, a plurality of load cells 7 are arranged below each of the weighing platforms, and the arrow C in the figure indicates the moving direction of the chain.

[0034] In this embodiment, the weight of coal scattered on each load plate is concentrated on the guide rails on both sides through the rollers installed on both sides of the weighing plate. The weight on the guide rails on both sides i...

Embodiment 3

[0041] This embodiment is an improvement of the second embodiment, which is the refinement of the second embodiment on the minor axis. The short axis described in this embodiment is coaxial with the chain link rotation axis of the chain, such as figure 2 shown.

[0042] The minor axis described in this embodiment is actually the extension of the chain link's rotation axis. The structure of the short shaft in this way is simple, and the stress is better. Since it is the same shaft as the chain link rotation shaft, it is more convenient to lubricate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com