Patents

Literature

82 results about "Weigh in motion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

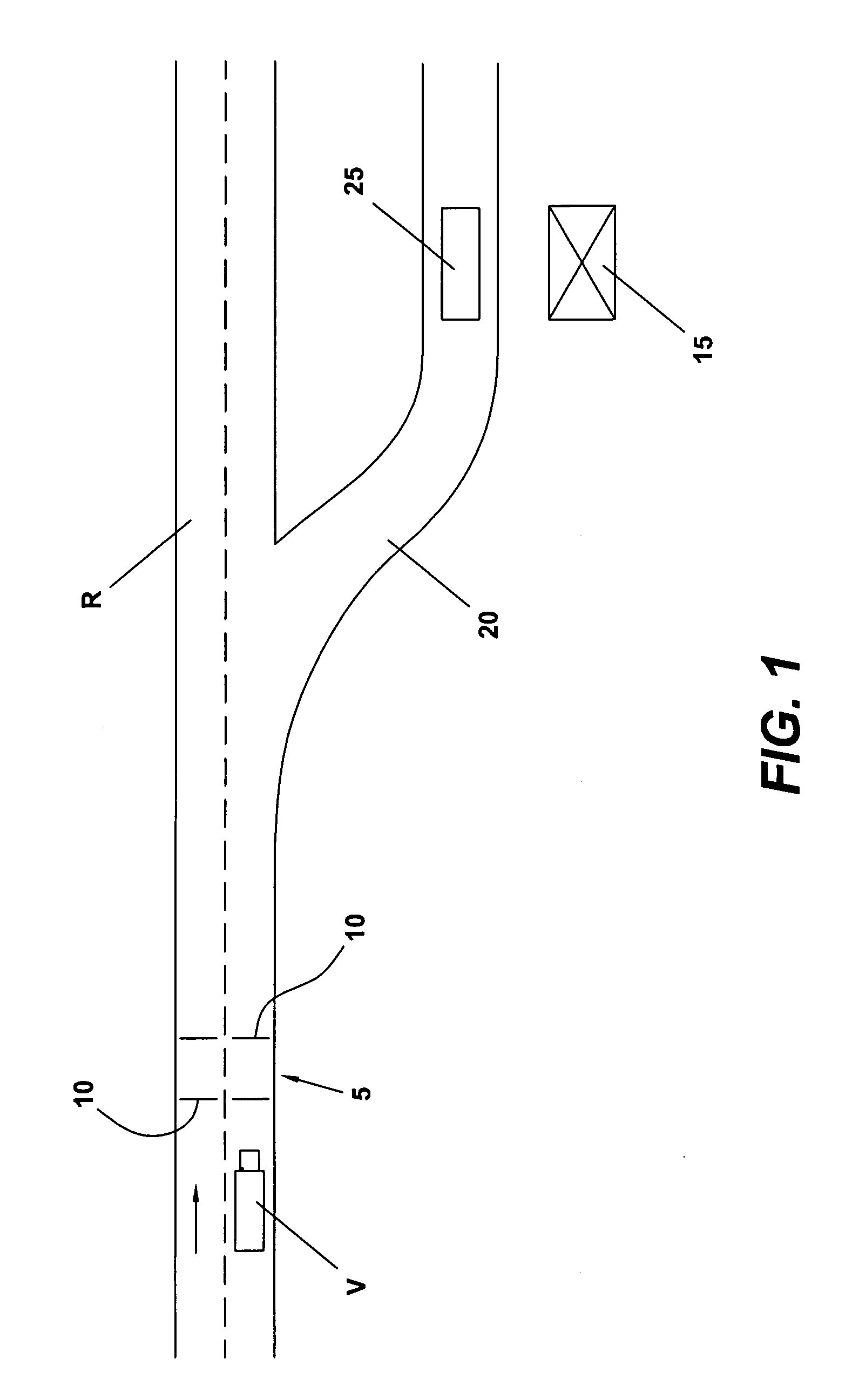

Weigh-in-motion or weighing-in-motion (WIM) devices are designed to capture and record the axle weights and gross vehicle weights as vehicles drive over a measurement site. Unlike static scales, WIM systems are capable of measuring vehicles traveling at a reduced or normal traffic speed and do not require the vehicle to come to a stop. This makes the weighing process more efficient, and, in the case of commercial vehicles, allows for trucks under the weight limit to bypass static scales or inspection.

System and method for indentifying, validating, weighing and characterizing moving or stationary vehicles and cargo

InactiveUS20060111868A1Accurate dataEliminate errorsDigital computer detailsWeighing apparatus for materials with special property/formElectronic communicationEngineering

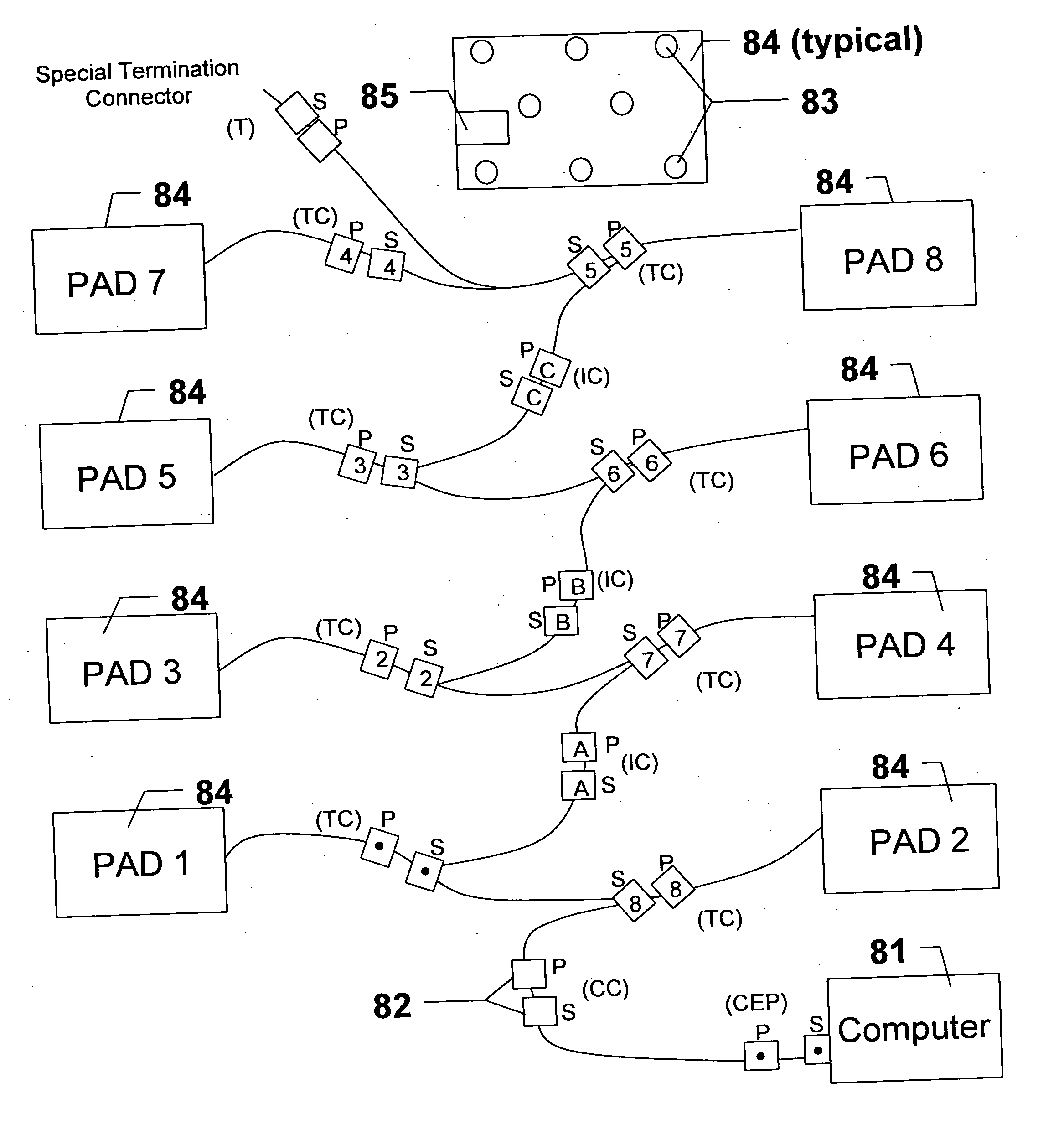

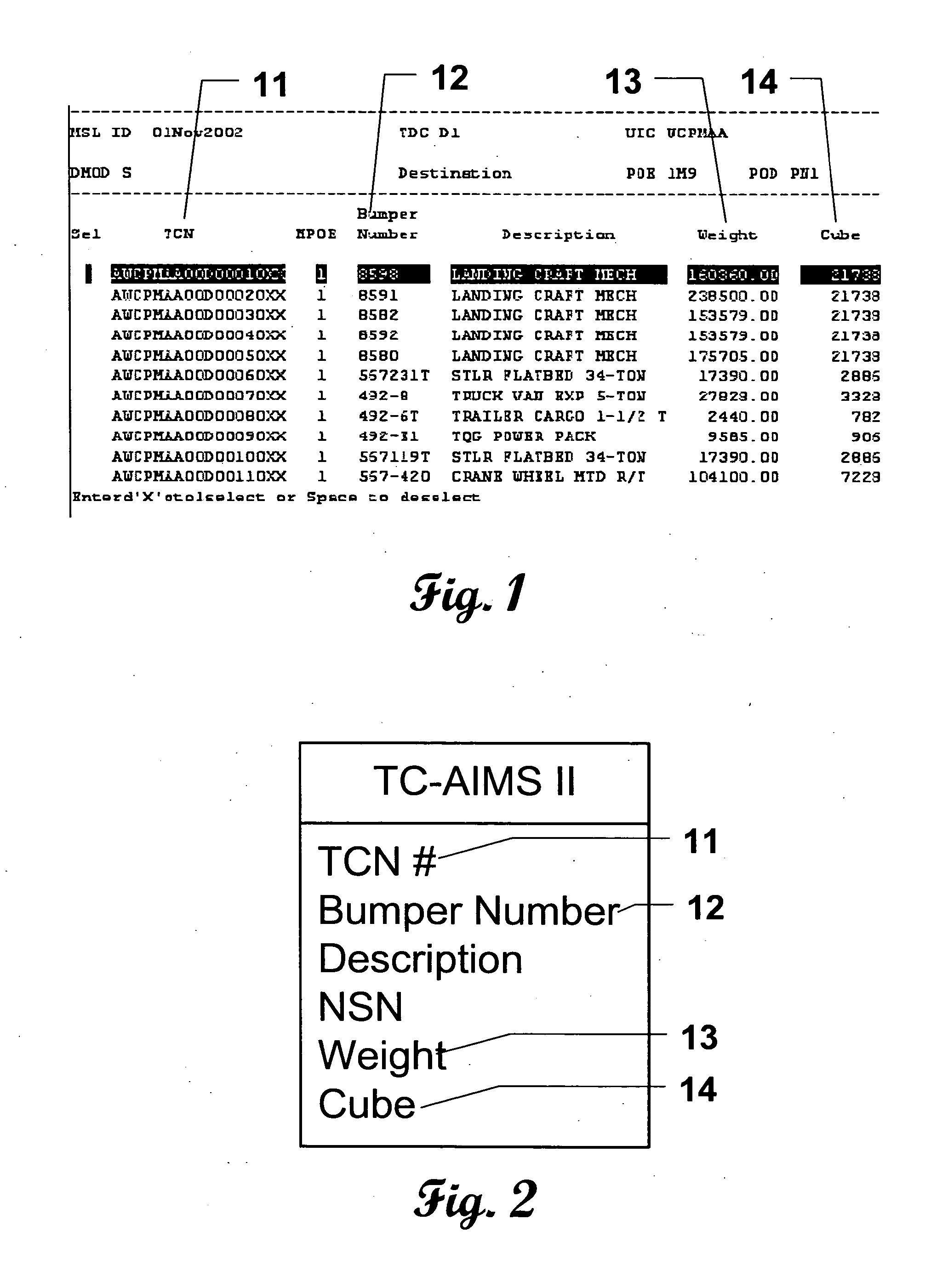

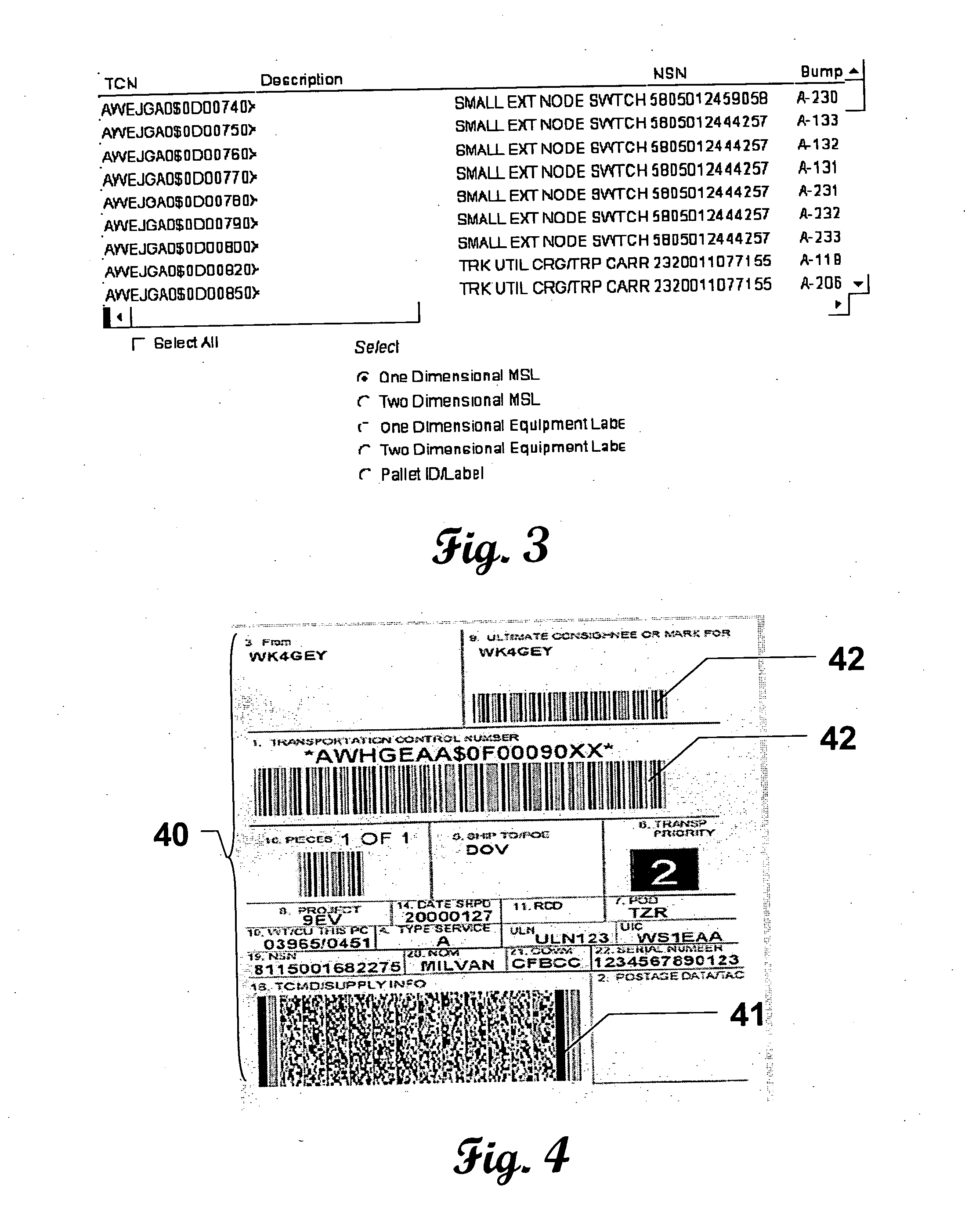

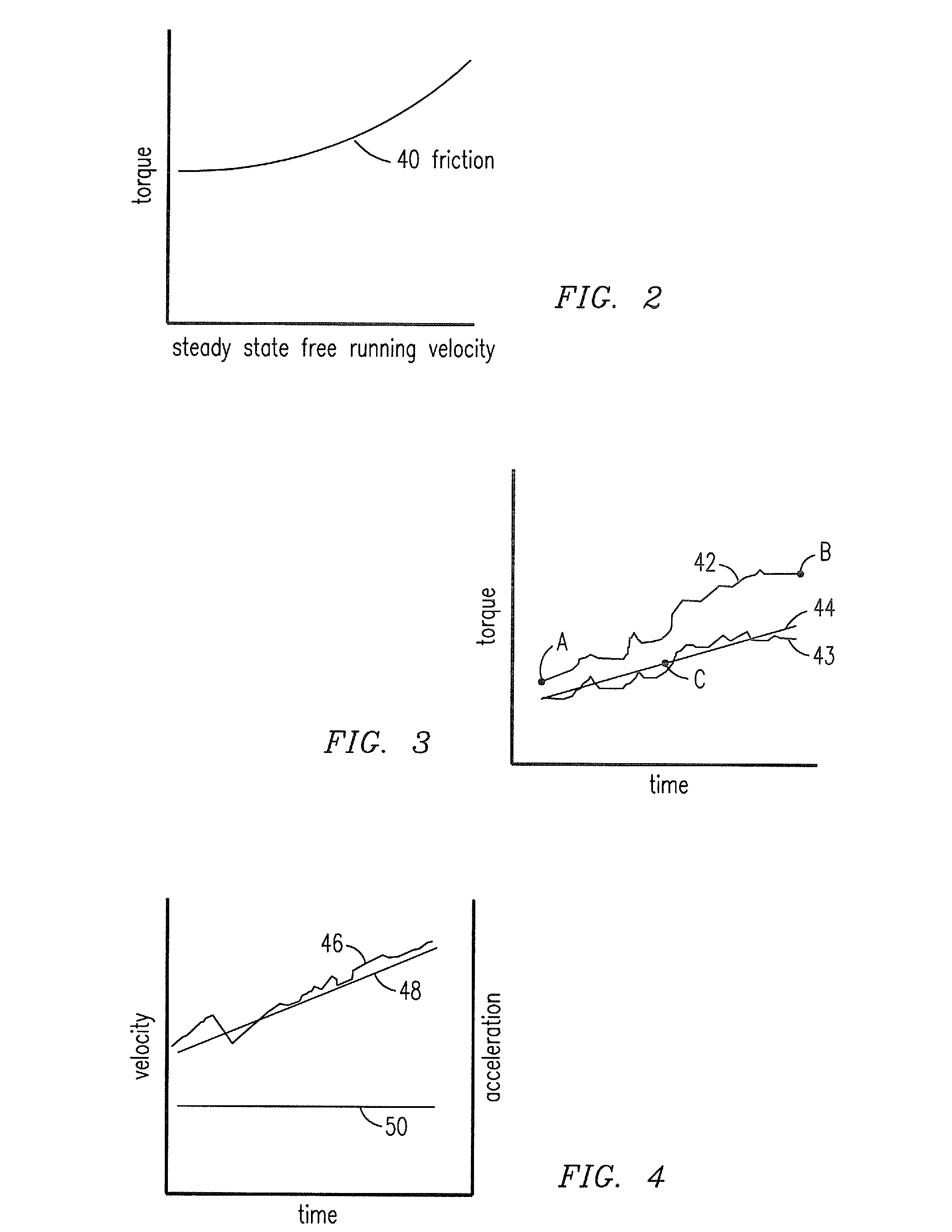

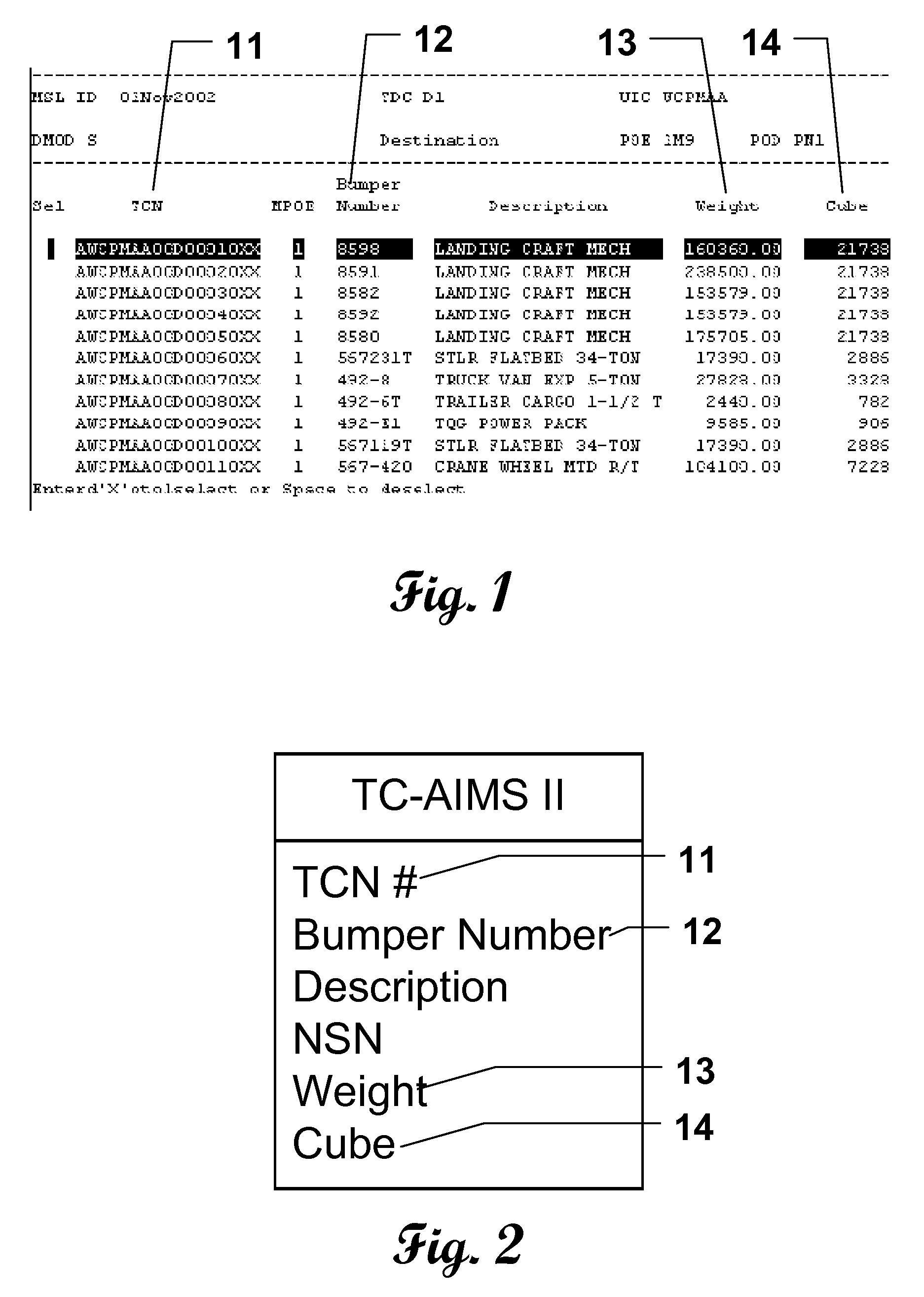

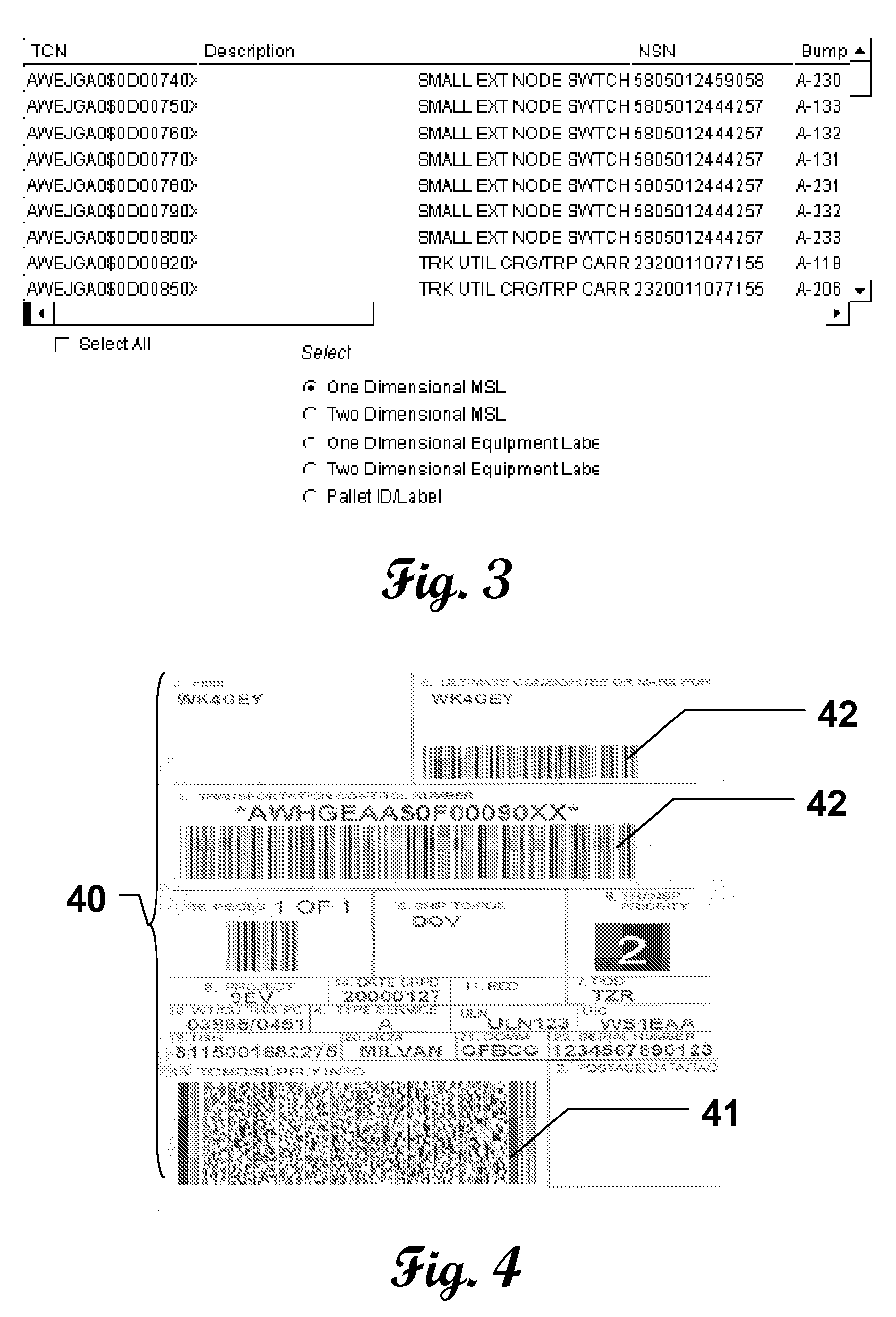

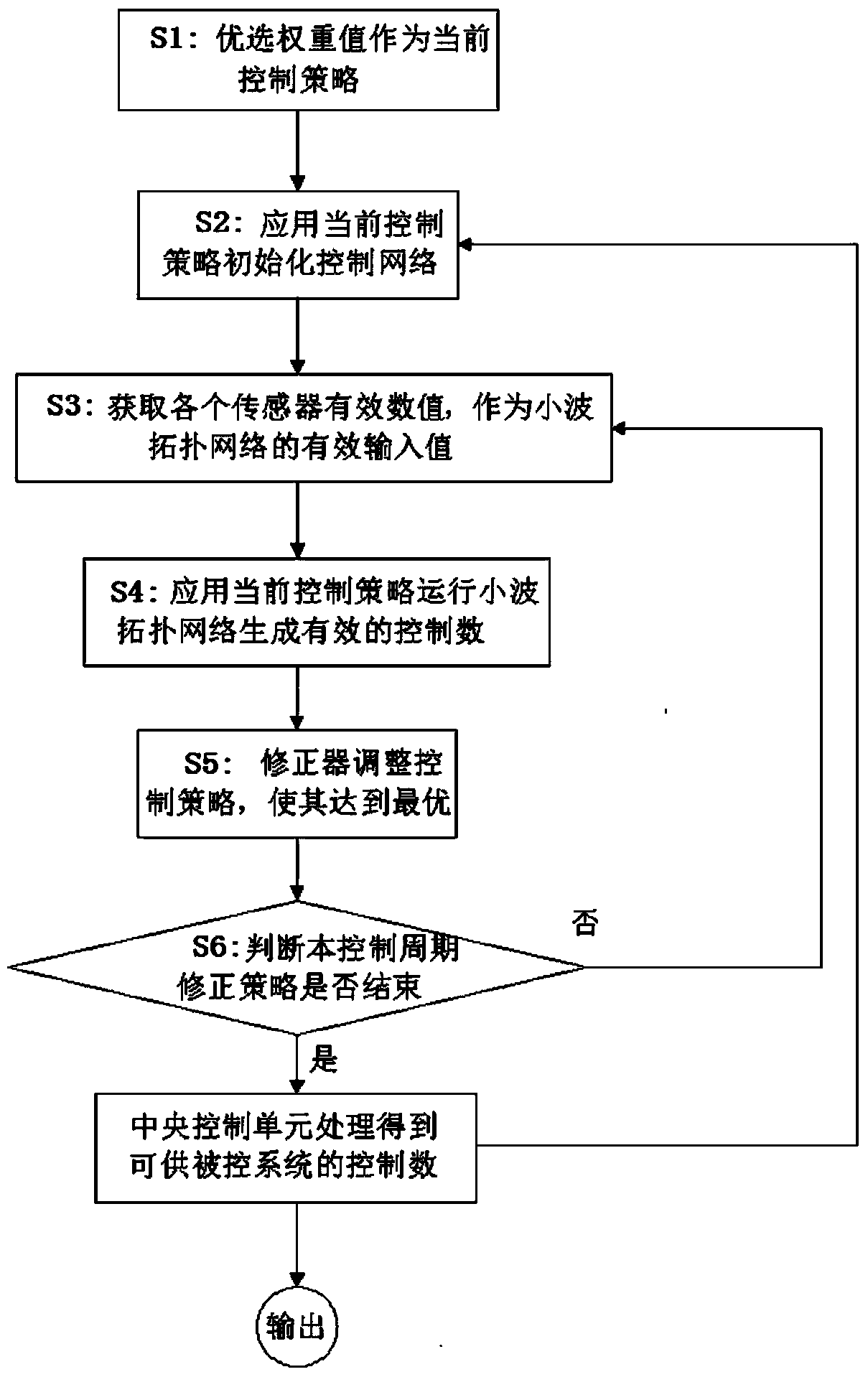

An asset identification and information infrastructure management (AI3M) device having an automated identification technology system (AIT), a Transportation Coordinators' Automated Information for Movements System II (TC-AIMS II), a weigh-in-motion system (WIM-II), and an Automated Air Load Planning system (AALPS) all in electronic communication for measuring and calculating actual asset characteristics, either statically or in-motion, and further calculating an actual load plan.

Owner:UT BATTELLE LLC

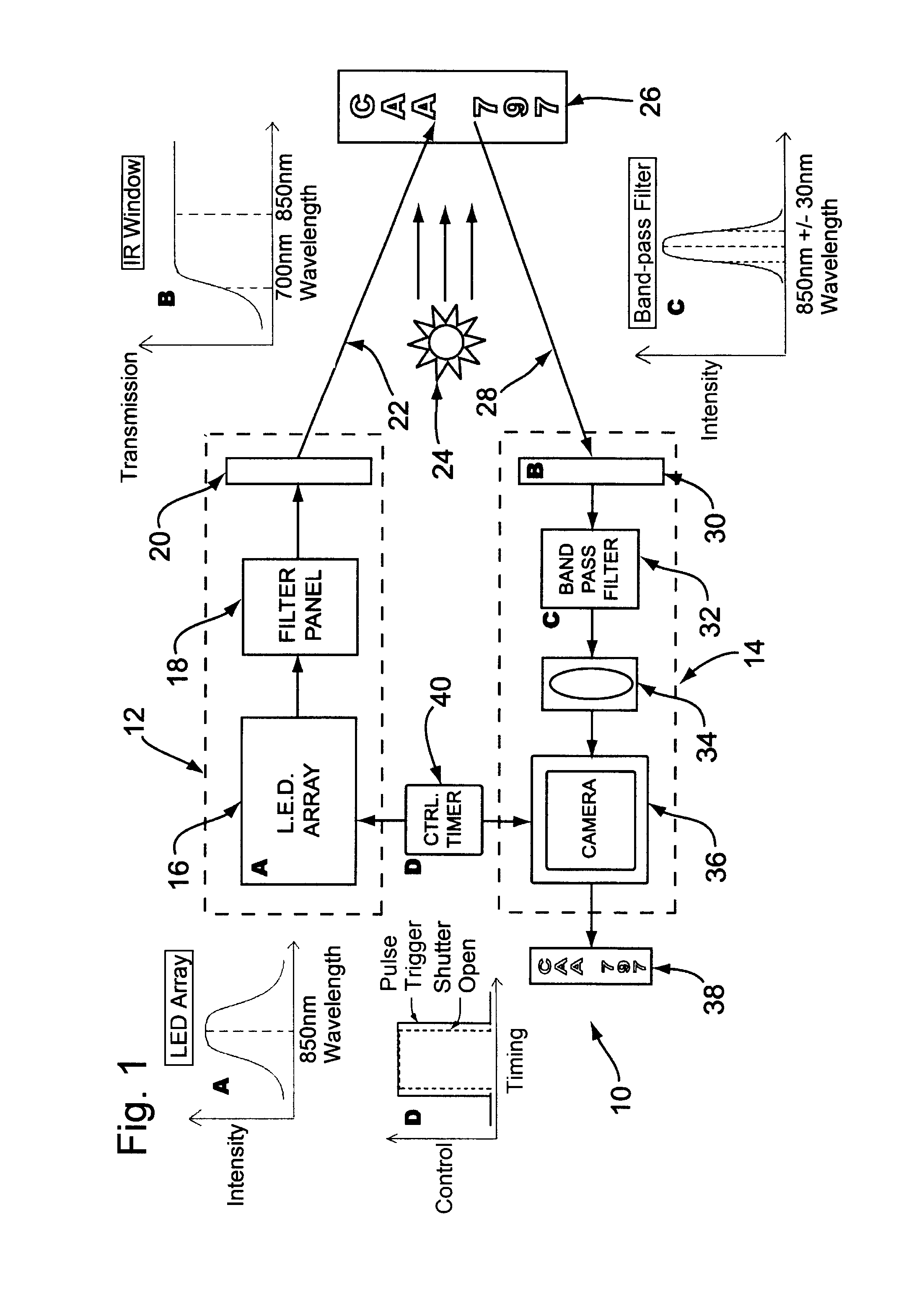

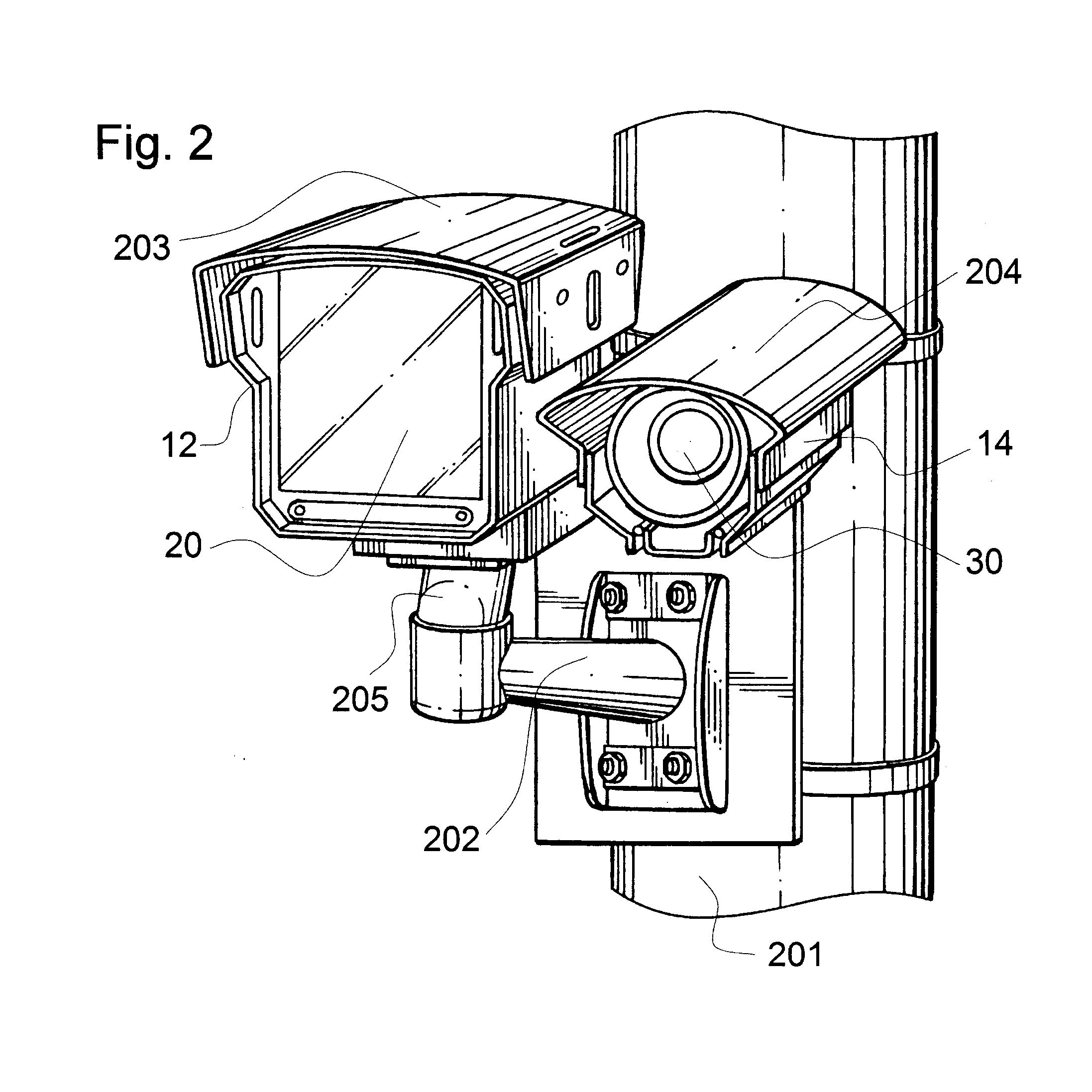

Non-retro-reflective license plate imaging system

InactiveUS20120002045A1Reduce ambient light intakeLow costTelevision system detailsRoad vehicles traffic controlEffect lightWeigh in motion

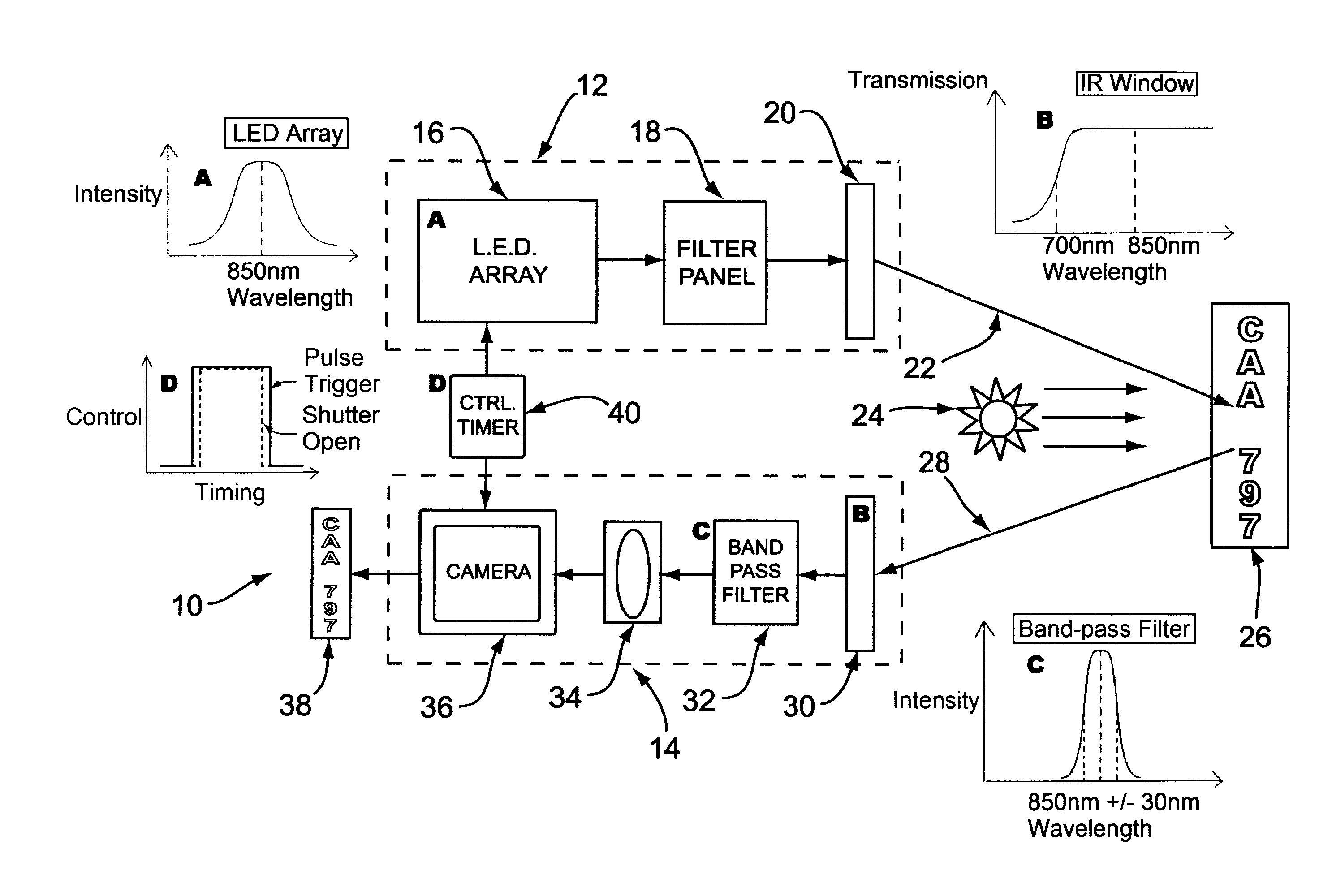

An infrared illuminator and camera system for high contrast imaging of non-retro-reflective license plates utilizing a combination of temporal filtering via pulsed LED illumination, spectral filtering using high transmission narrow band pass optical filters placed directly on the CCD sensor, and an IR sensitive camera with adjustable computer controlled settings to produce high definition, high contrast images of a wide range of both retro-reflective and non-retro-reflective surfaces including vehicle license plates, ISO shipping containers, and transport trucks with DOT ID numbers on fenders for use in weigh in motion systems, and can operate in all lighting conditions from total darkness to bright sunlight.

Owner:BOSCH SECURITY SYST INC

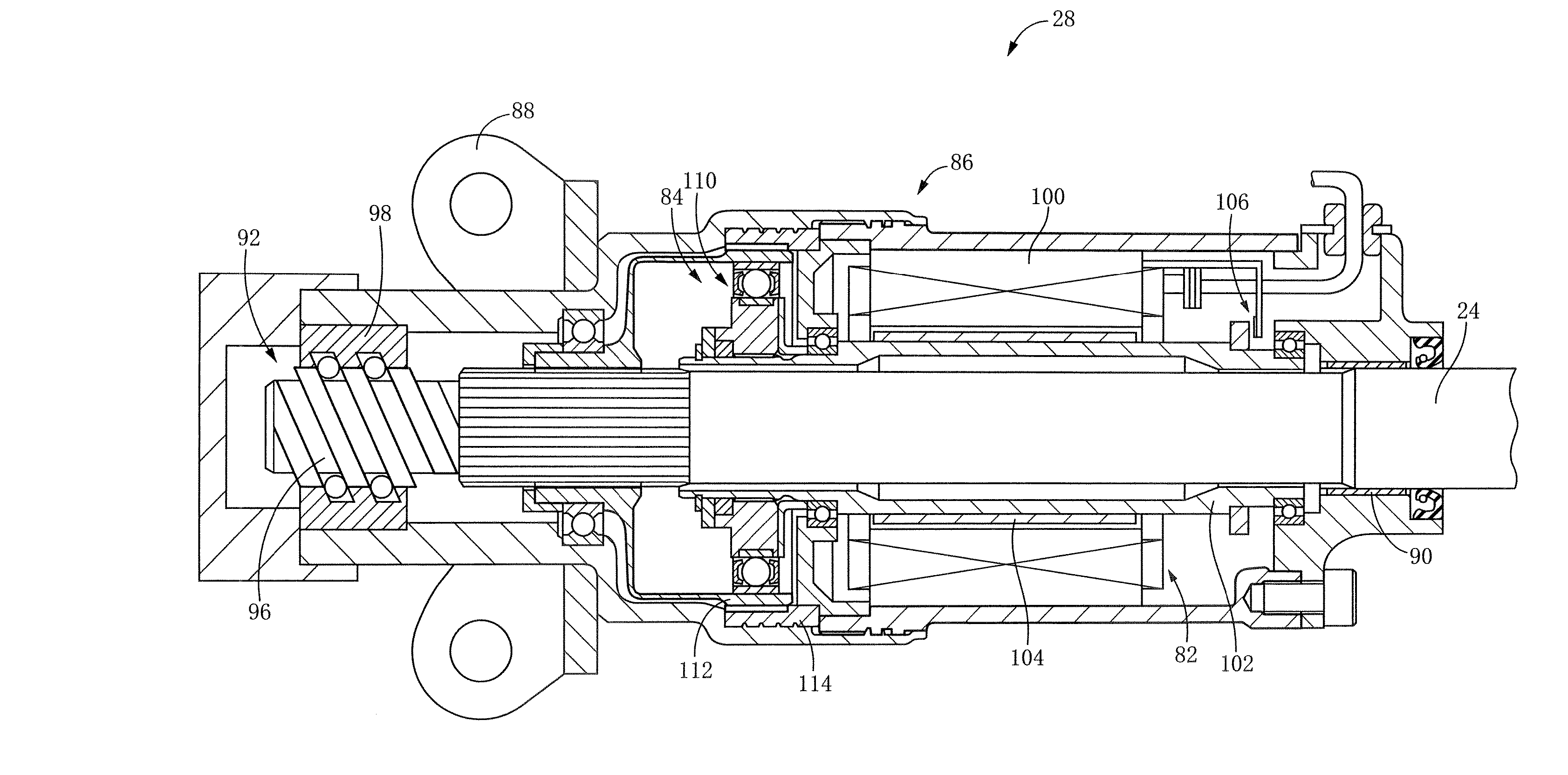

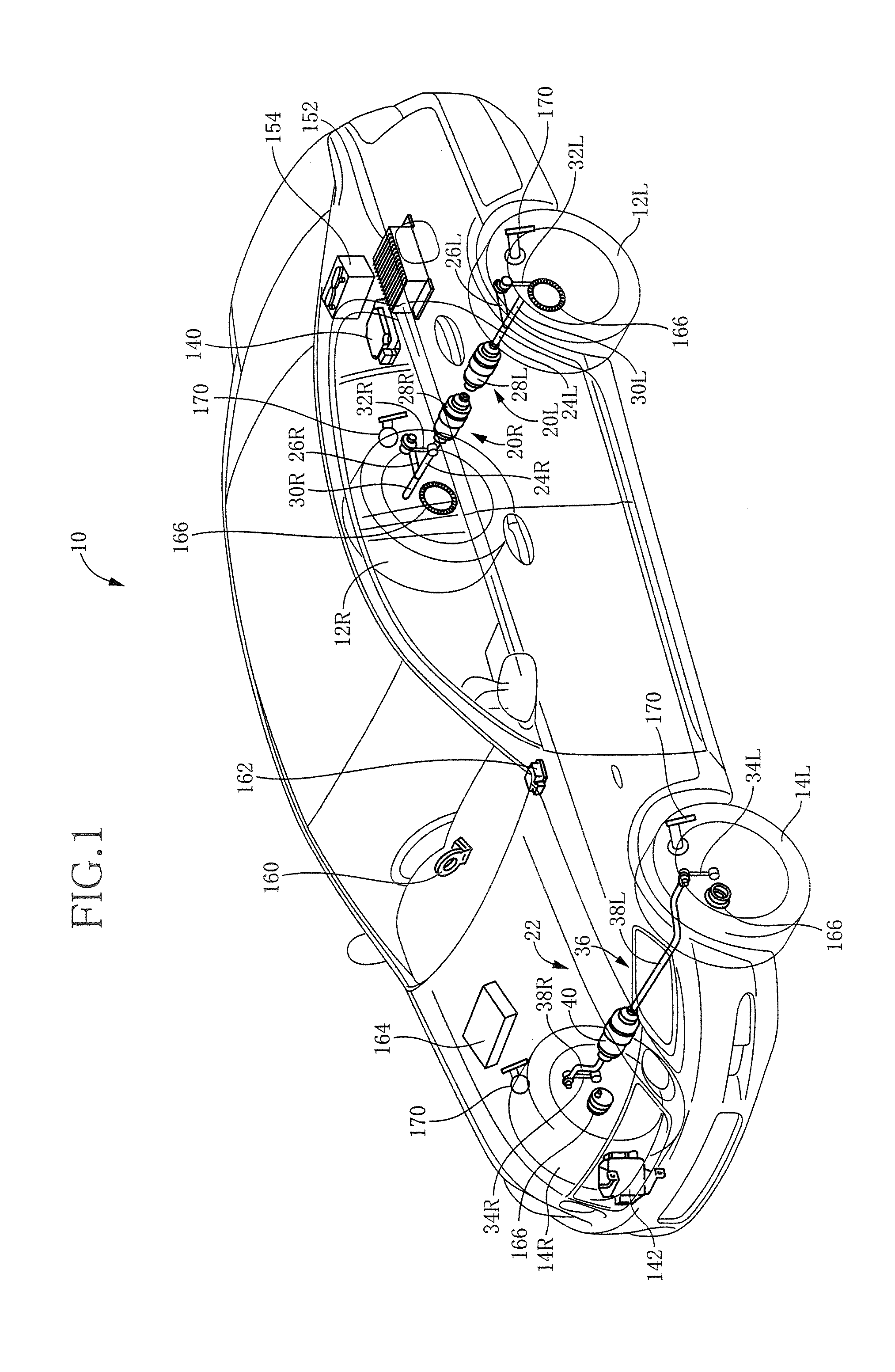

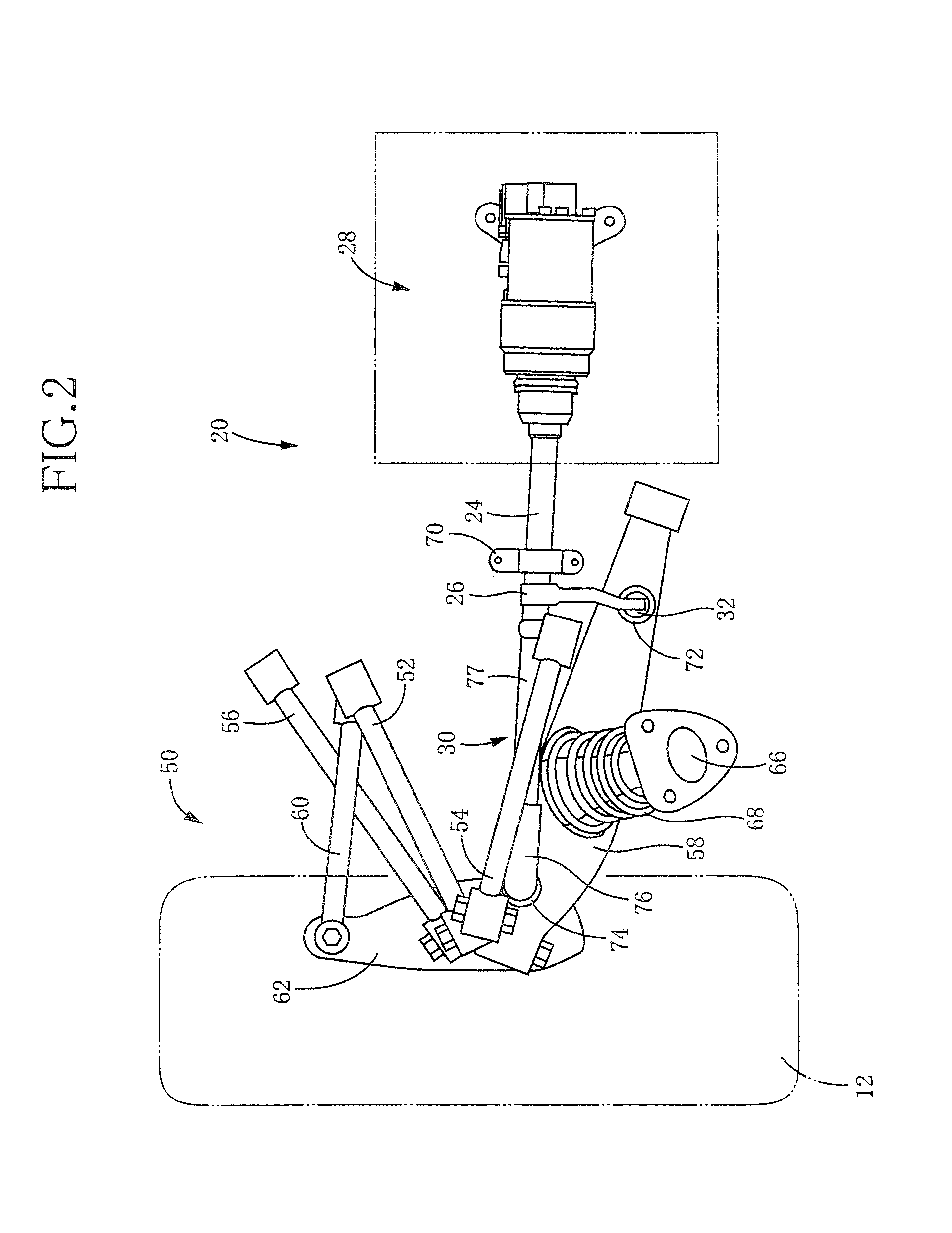

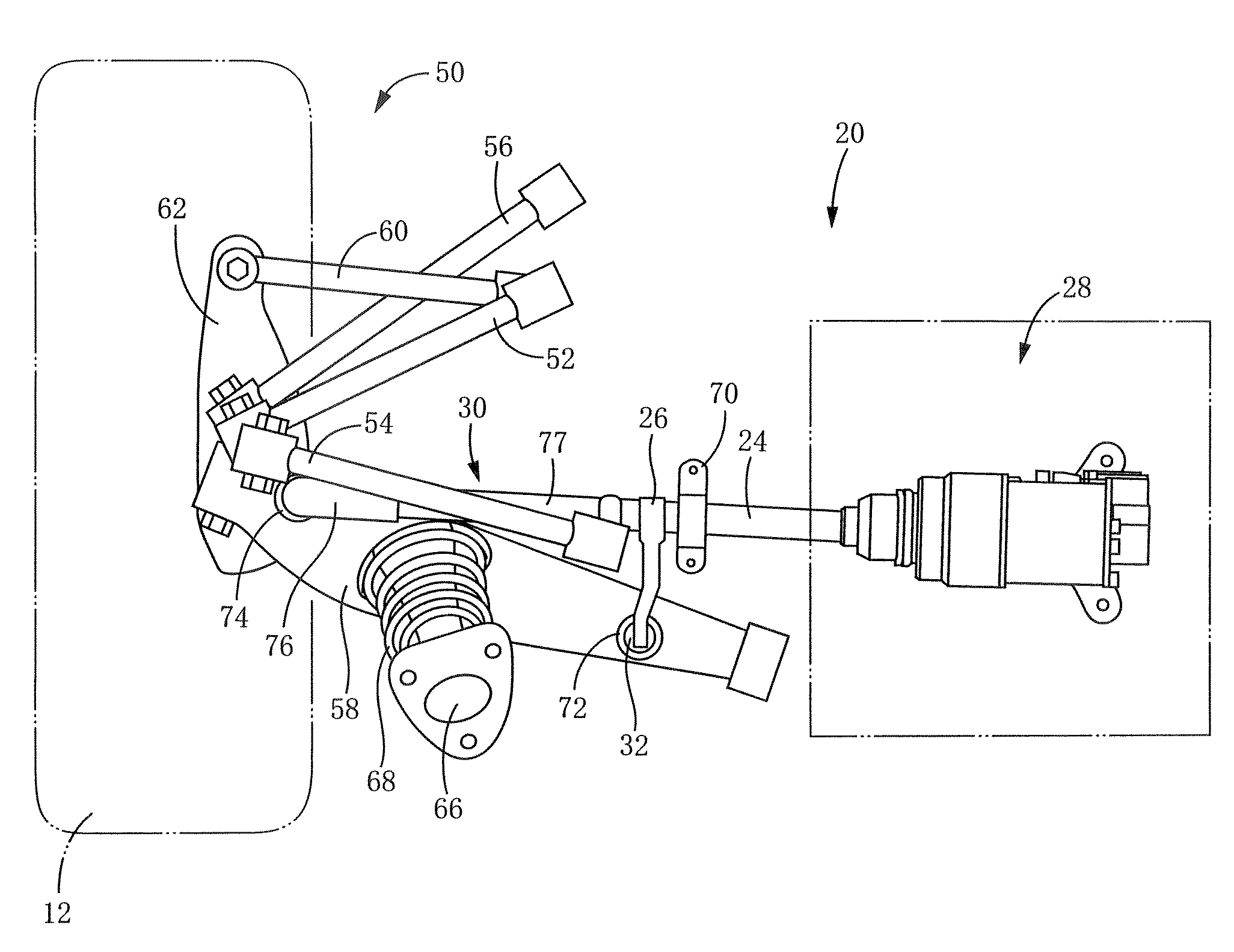

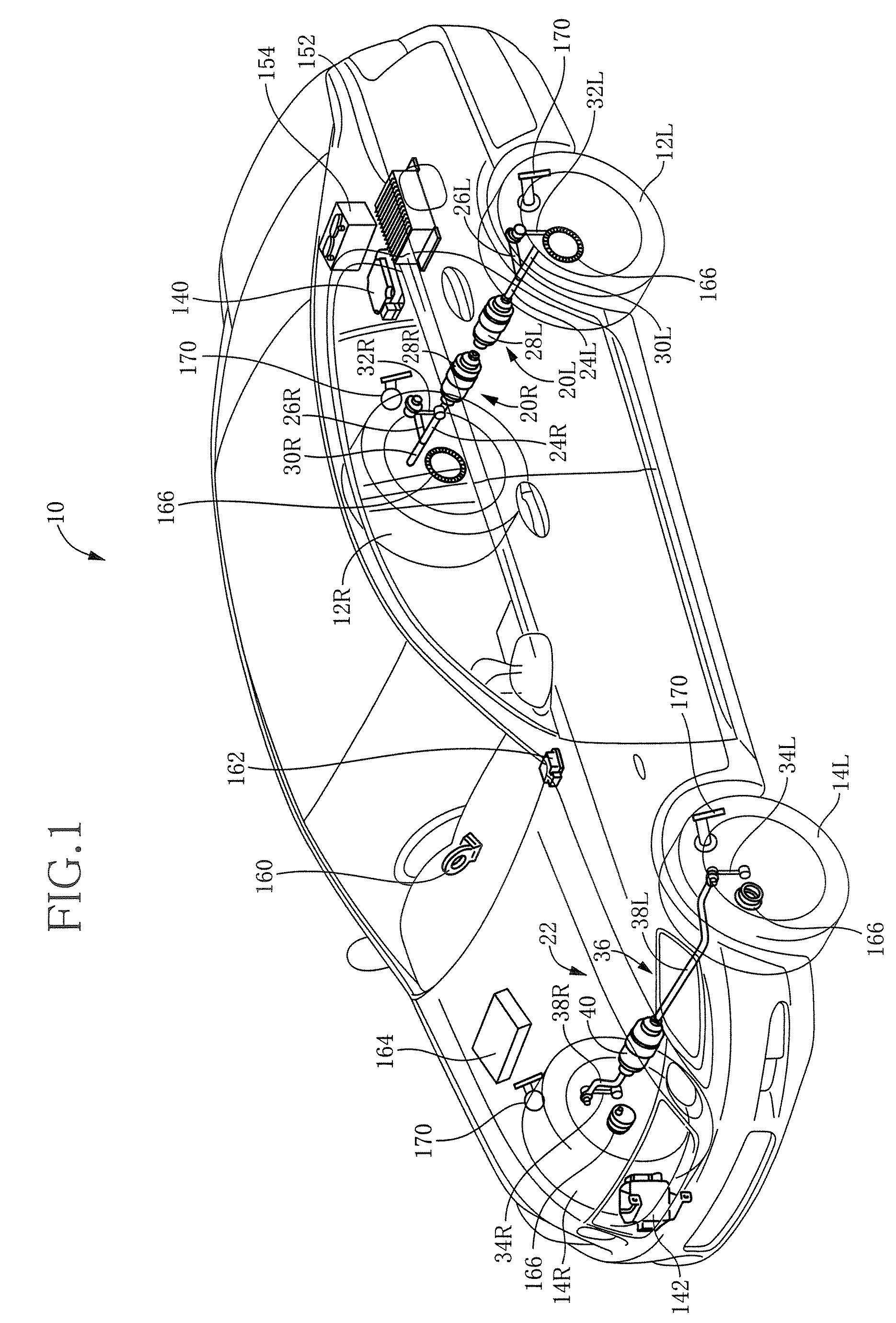

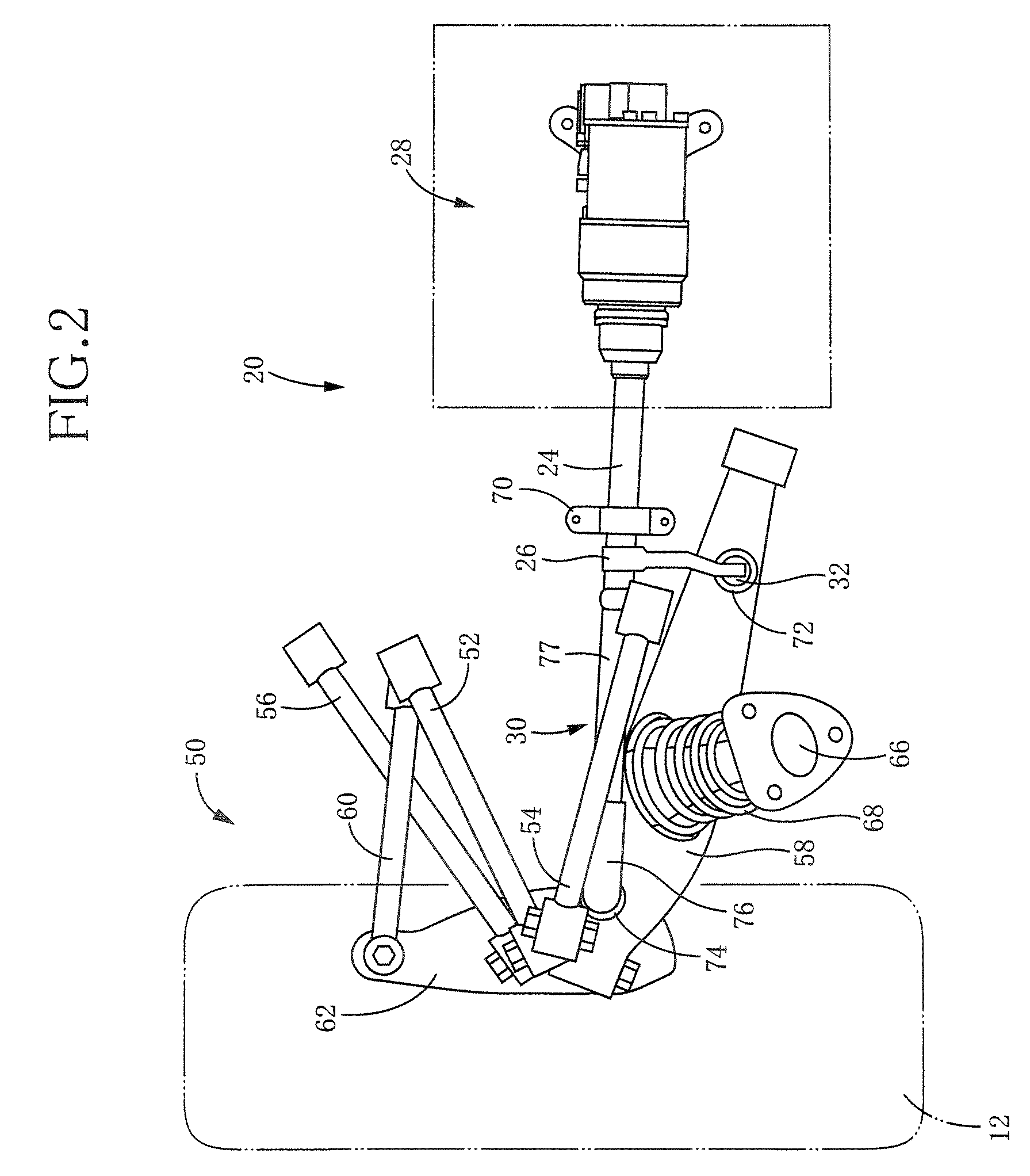

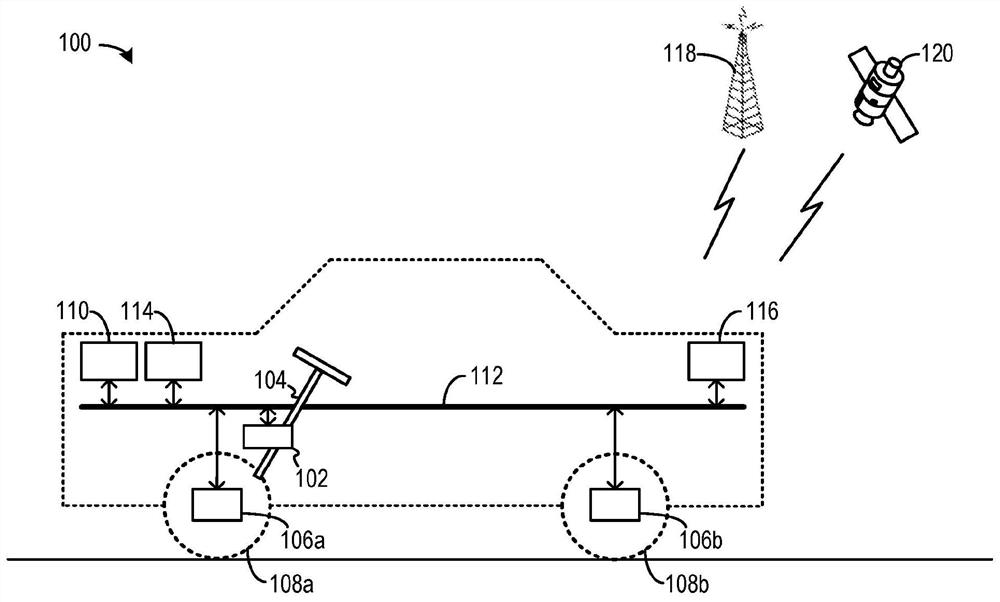

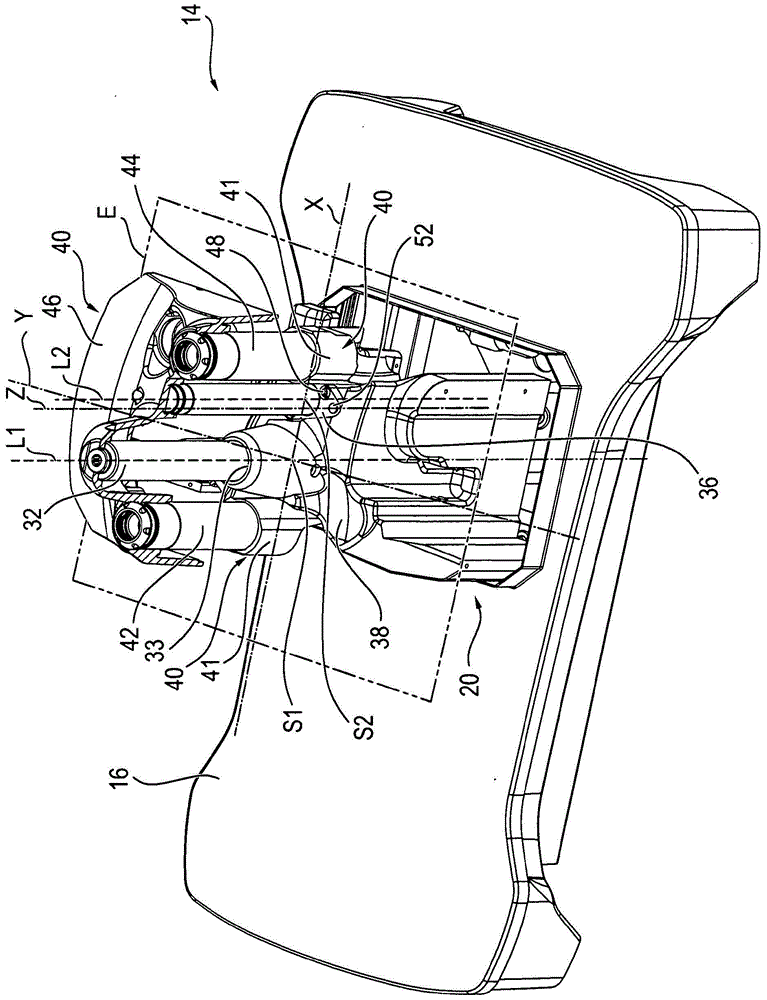

Device for changing distance between wheel and vehicle body, and system including the device

InactiveUS20070290473A1Reduce spacingAdjustable distanceVehicle cleaning apparatusLoading/unloading vehicle arrangmentEngineeringActuator

An adjuster device includes (a) a shaft held by a vehicle body; (b) an arm extending from the shaft in a direction intersecting an axial direction of the shaft; (c) an actuator causing one of rotation of the shaft and axial movement of the shaft in the axial direction; and (d) a motion converter converting the one of the rotation of the shaft and the axial movement of the shaft, into the other of the rotation of the shaft and the axial movement of the shaft. The arm is connected at a distal end portion thereof to one of at least one suspension arm, so as to enable the rotation of the shaft to cause change in a vertical distance between a wheel and the vehicle body. The shaft is connected to one of the at least one suspension arm and / or to an axle carrier, so as to enable the axial movement of the shaft to cause change in an alignment of the wheel. Also disclosed is an adjusting system including the adjuster device.

Owner:TOYOTA JIDOSHA KK

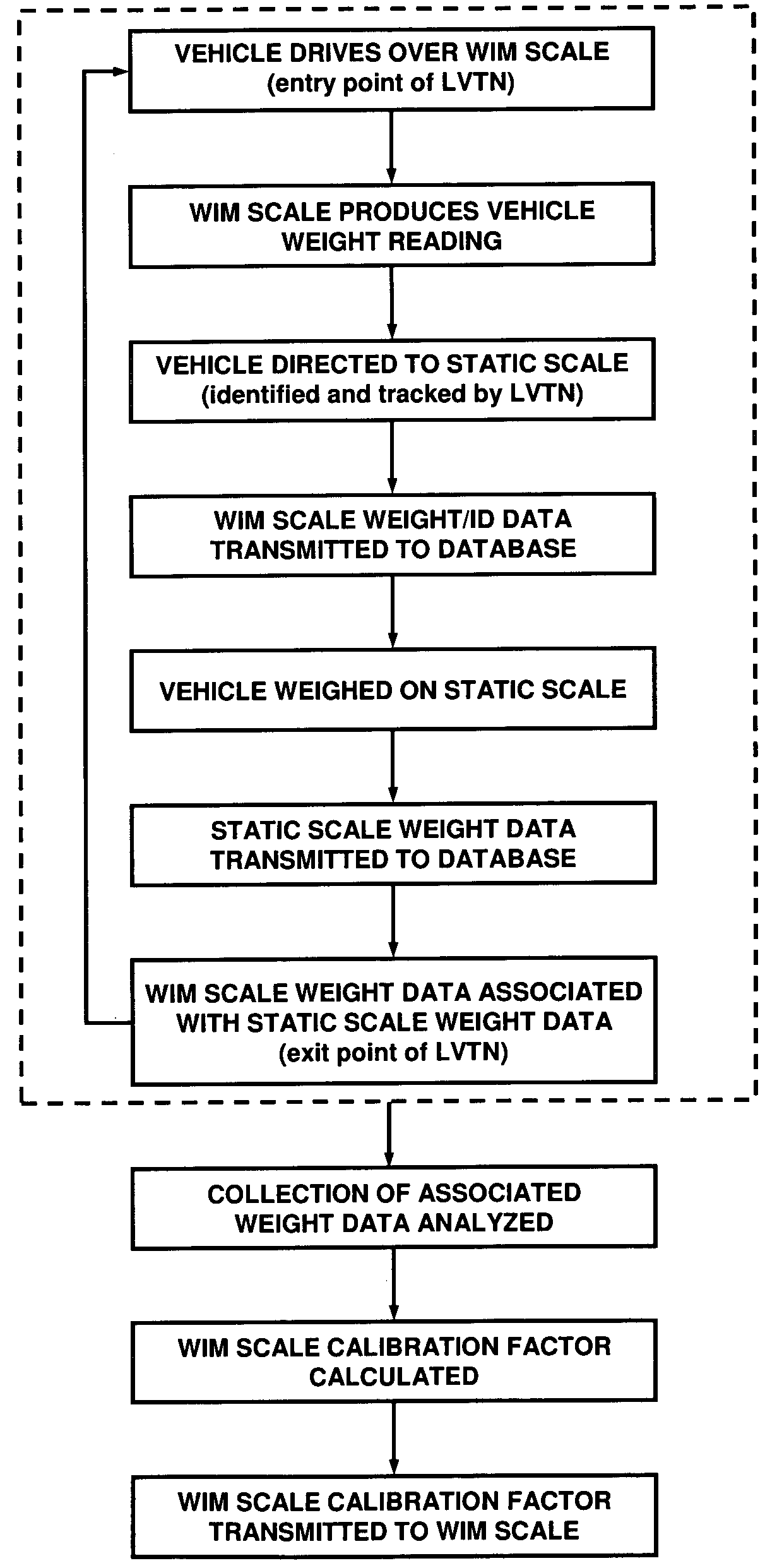

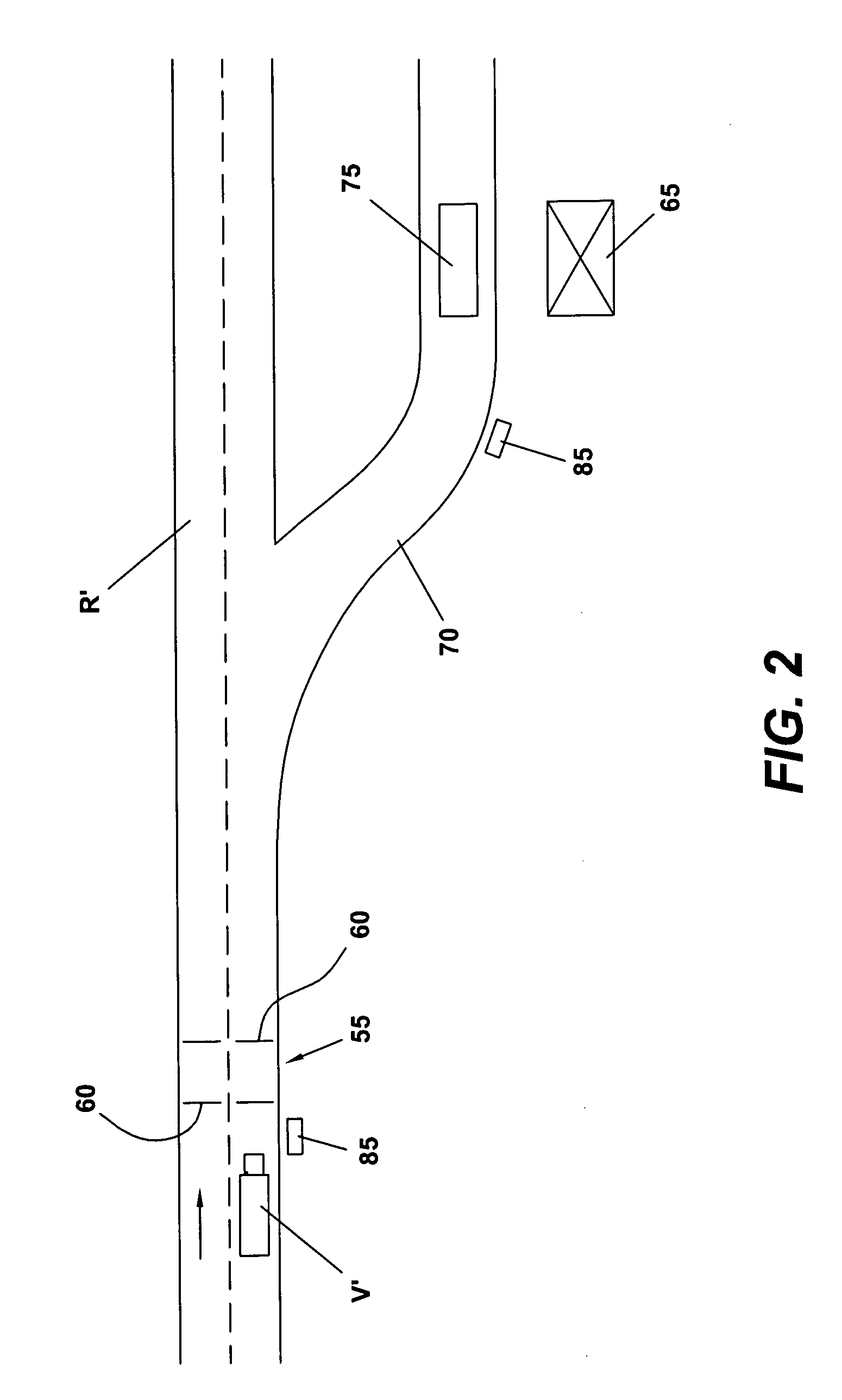

Weigh-in-motion system with auto-calibration

ActiveUS20090151421A1Accurate readingWeighing apparatus testing/calibrationSpecial data processing applicationsMobile vehicleComputer science

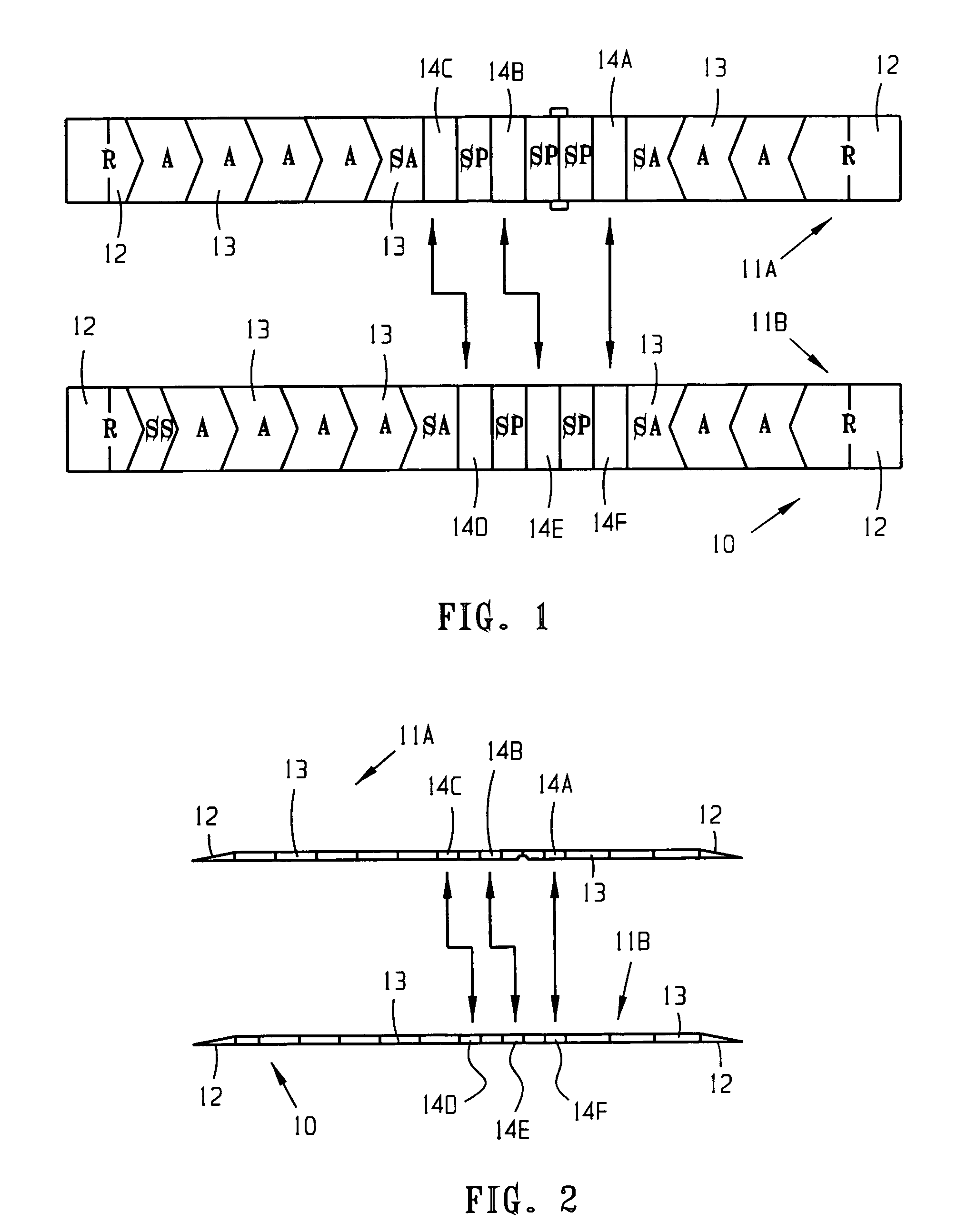

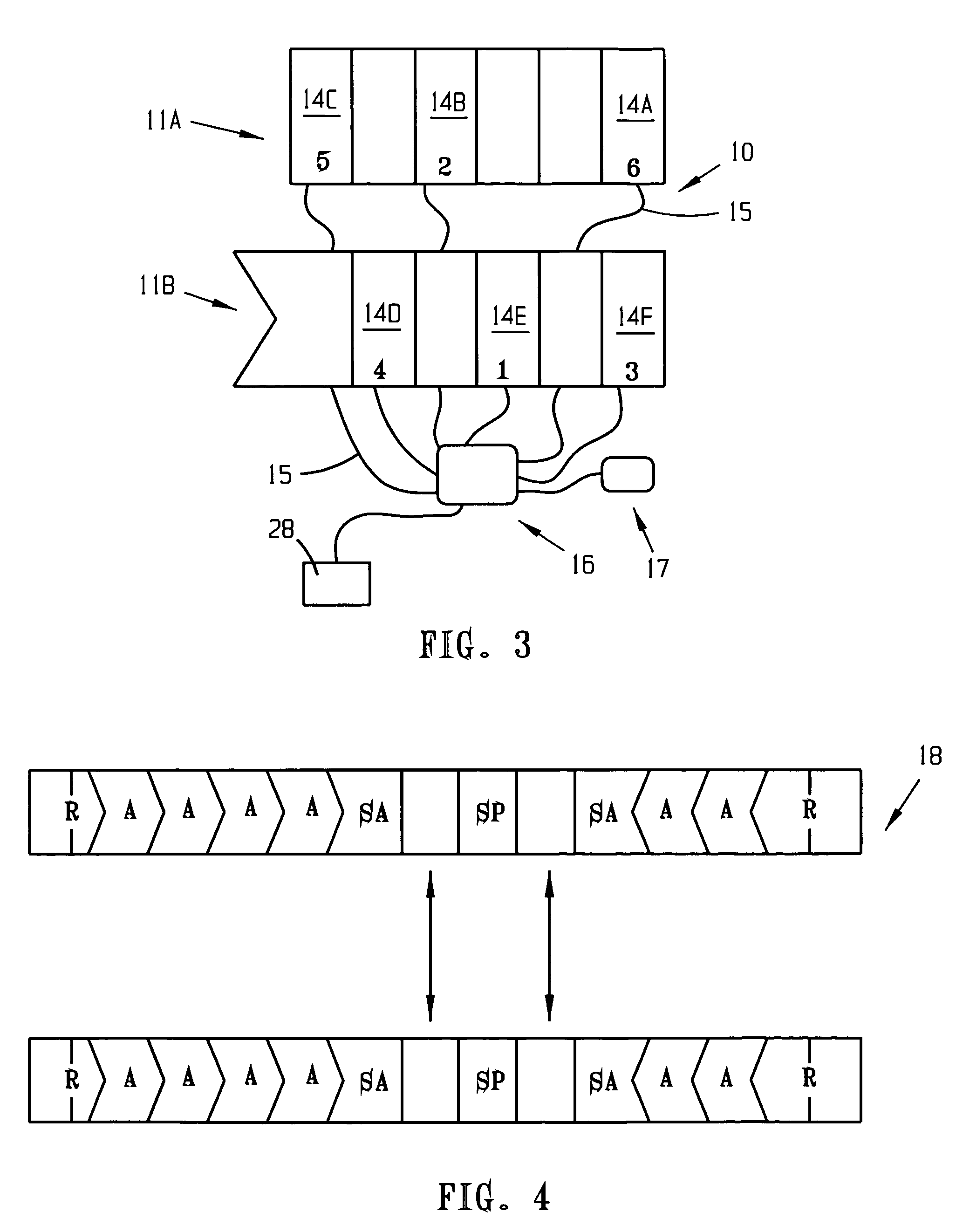

Weigh-in-motion (WIM) systems for weighing moving vehicles, the systems having the ability to automatically determine and periodically apply calibration factors to WIM scale readings. Auto-calibration may include transferring both WIM and static weight readings for the same vehicle to a database, associating the weight readings, collecting a number of such weight readings, and analyzing the differences between the WIM and static weight readings to calculate WIM scale calibration factors. The calibration factors may be based on vehicle characteristics such as vehicle weight, vehicle class and / or vehicle speed at the WIM scale.

Owner:METTLER TOLEDO INC

Device for changing distance between wheel and vehicle body, and system including the device

InactiveUS7766344B2Adjust running characteristicReduce spacingInterconnection systemsResilient suspensionsEngineeringSuspension (vehicle)

An adjuster device includes (a) a shaft held by a vehicle body; (b) an arm extending from the shaft in a direction intersecting an axial direction of the shaft; (c) an actuator causing one of rotation of the shaft and axial movement of the shaft in the axial direction; and (d) a motion converter converting the one of the rotation of the shaft and the axial movement of the shaft, into the other of the rotation of the shaft and the axial movement of the shaft. The arm is connected at a distal end portion thereof to one of at least one suspension arm, so as to enable the rotation of the shaft to cause change in a vertical distance between a wheel and the vehicle body. The shaft is connected to one of the at least one suspension arm or to an axle carrier, so as to enable the axial movement of the shaft to cause change in an alignment of the wheel. Also disclosed is an adjusting system including the adjuster device.

Owner:TOYOTA JIDOSHA KK

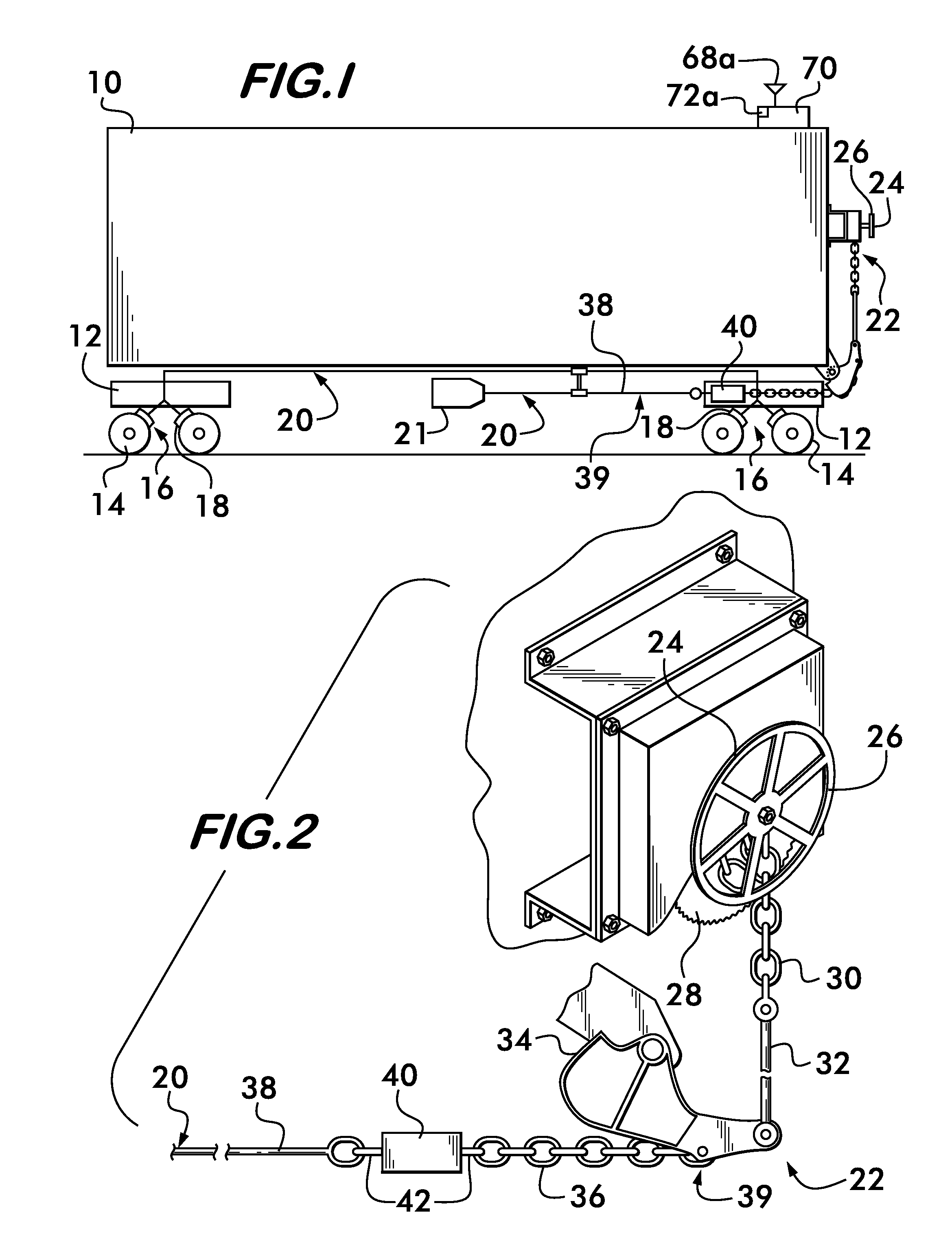

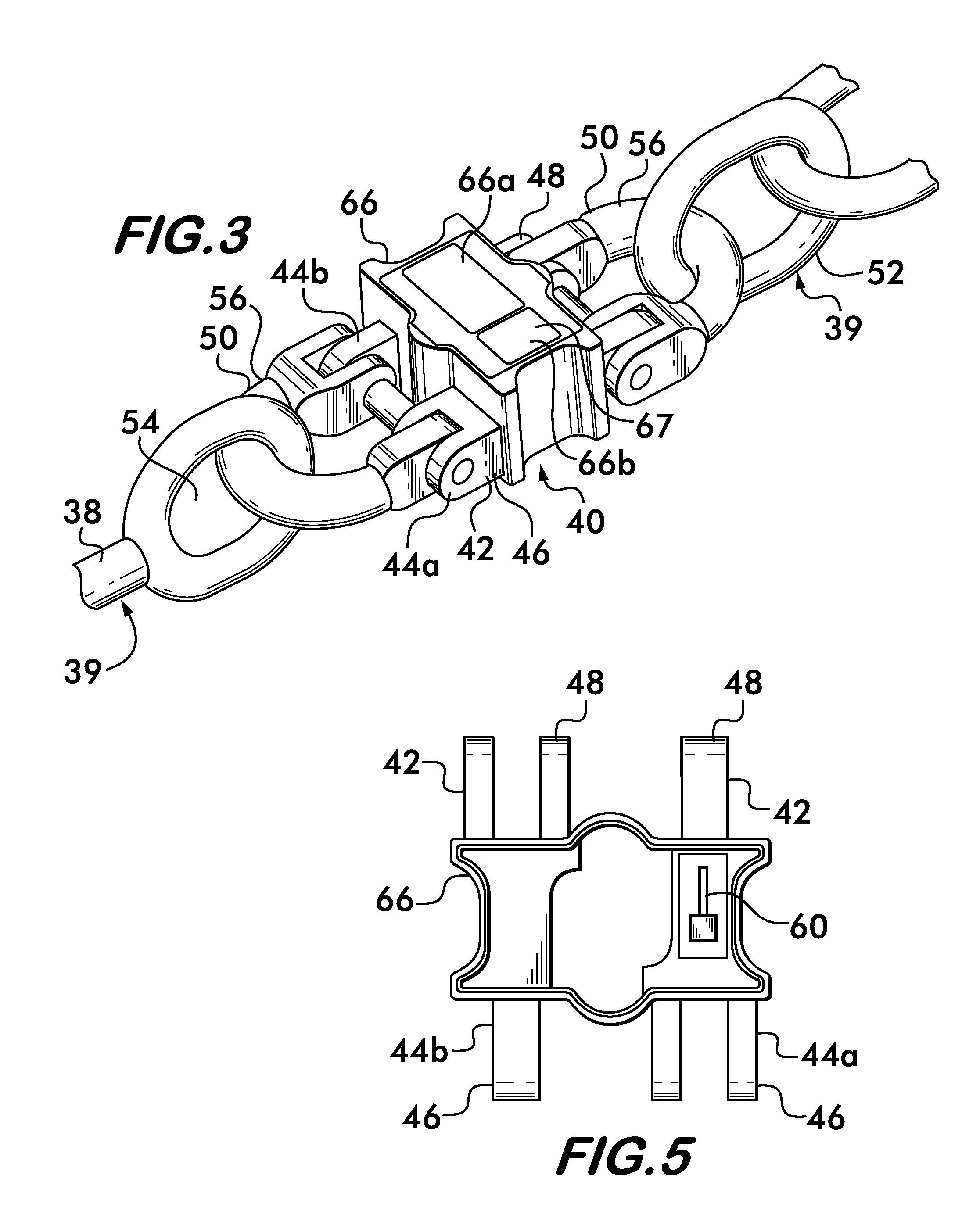

Railcar Handbrake Monitor

A device for monitoring the status of a railcar handbrake having a hand operated handle, which device has a load bearing member configured to be inserted in the linkage of a railcar handbrake system so that the force applied to the brake system passes through the load bearing member. A strain gauge mounted on the load bearing member measures the strain. The information from the strain gauge is indicative of the force applied by the handbrake to the brake and is used to determine the status of the handbrake. Means for determining motion of the railcar is also provided. In one form, if it is determined that the brake is on and the railcar is in motion, information, such as an alarm, is transmitted. A system and method of monitoring a railcar handbrake are also provided.

Owner:AMSTED RAIL CO INC

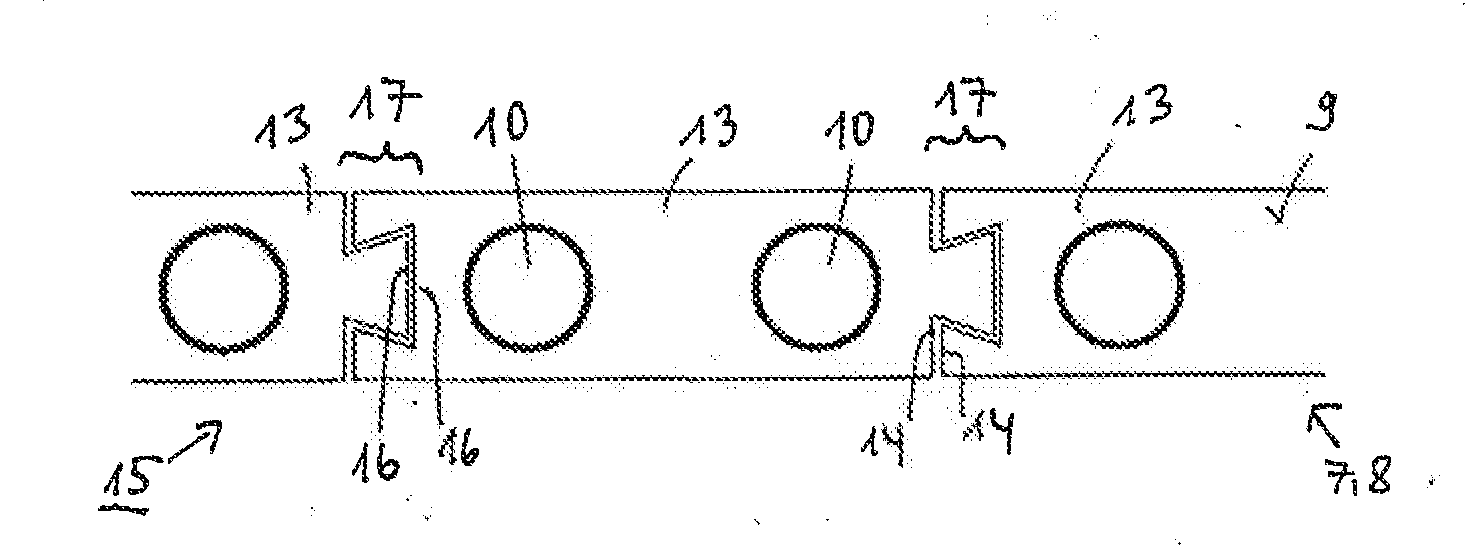

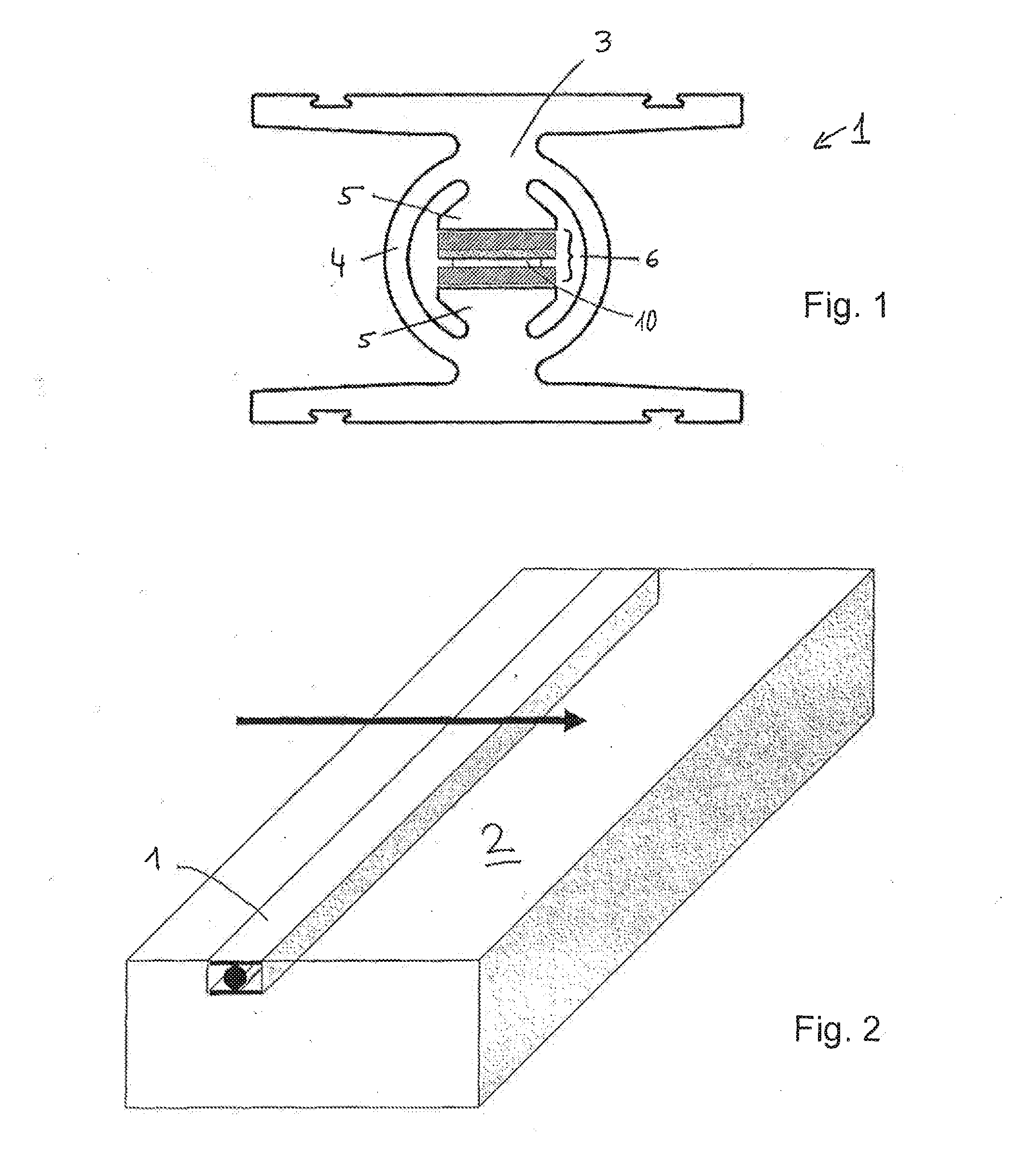

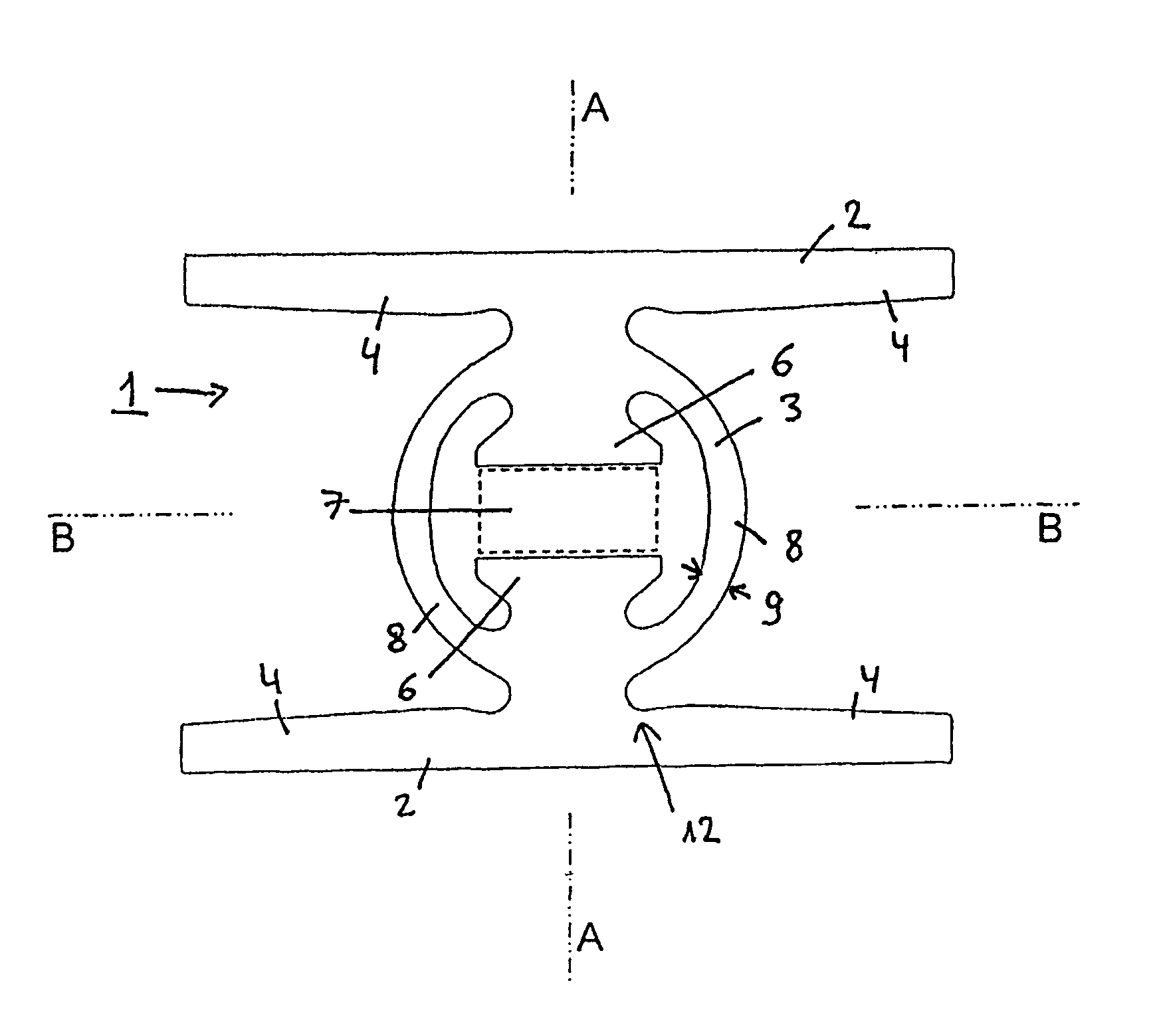

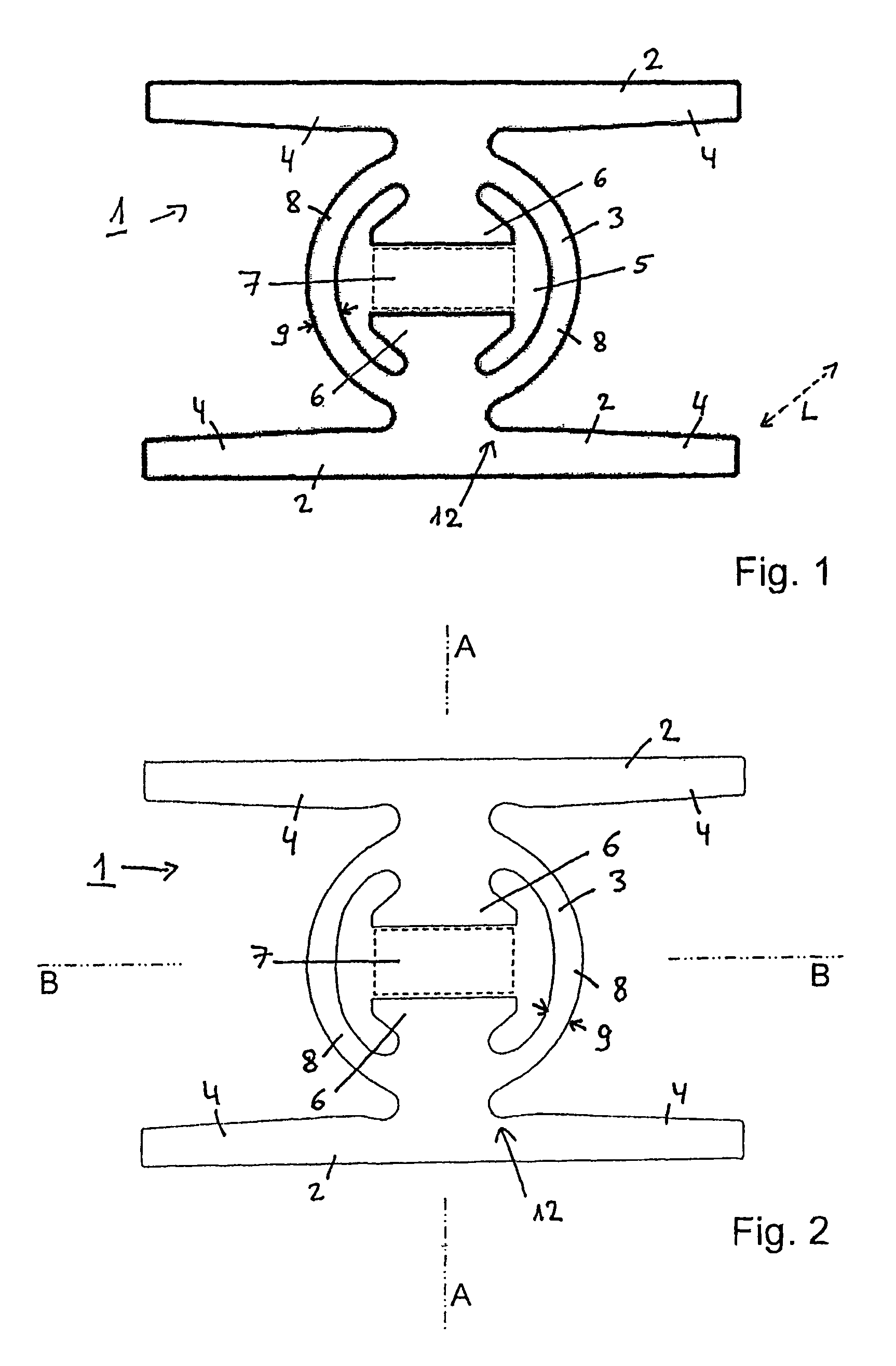

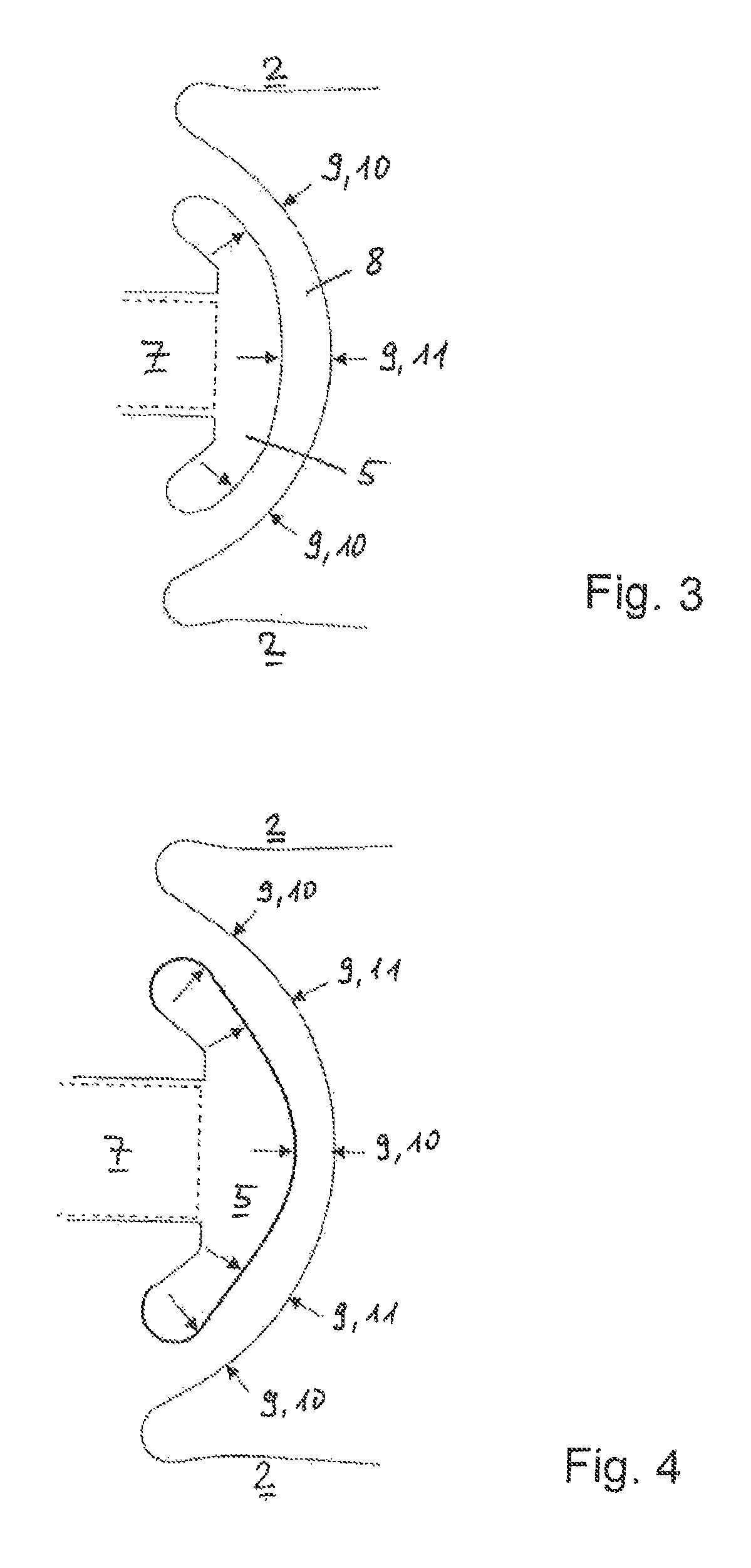

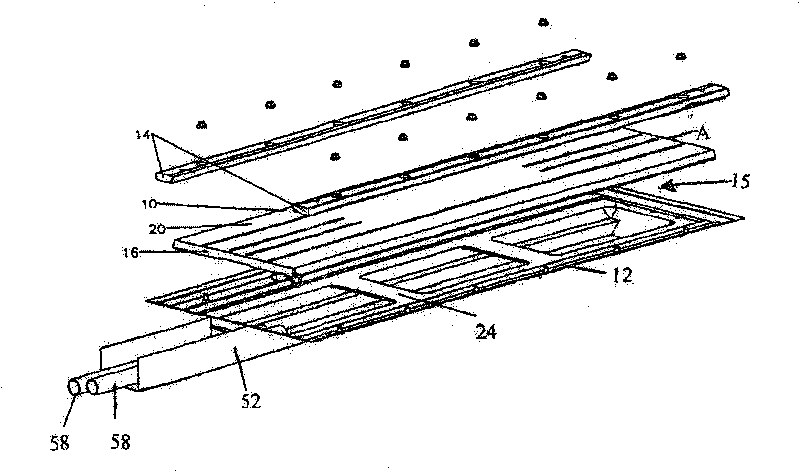

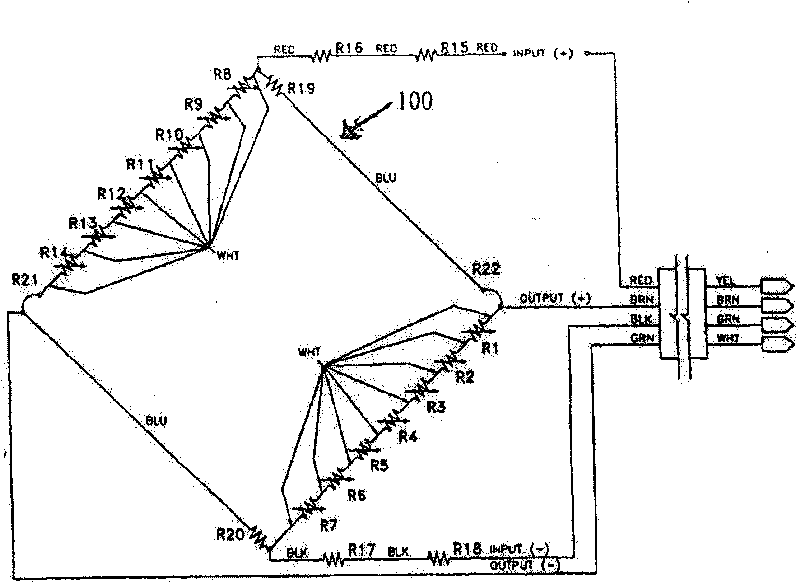

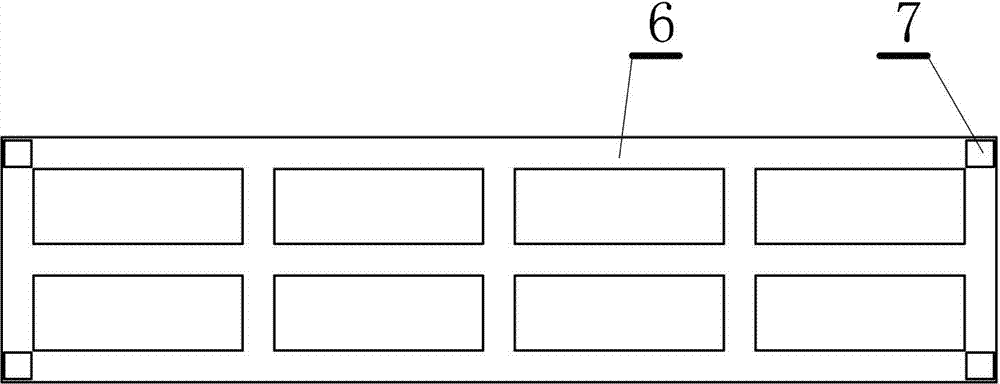

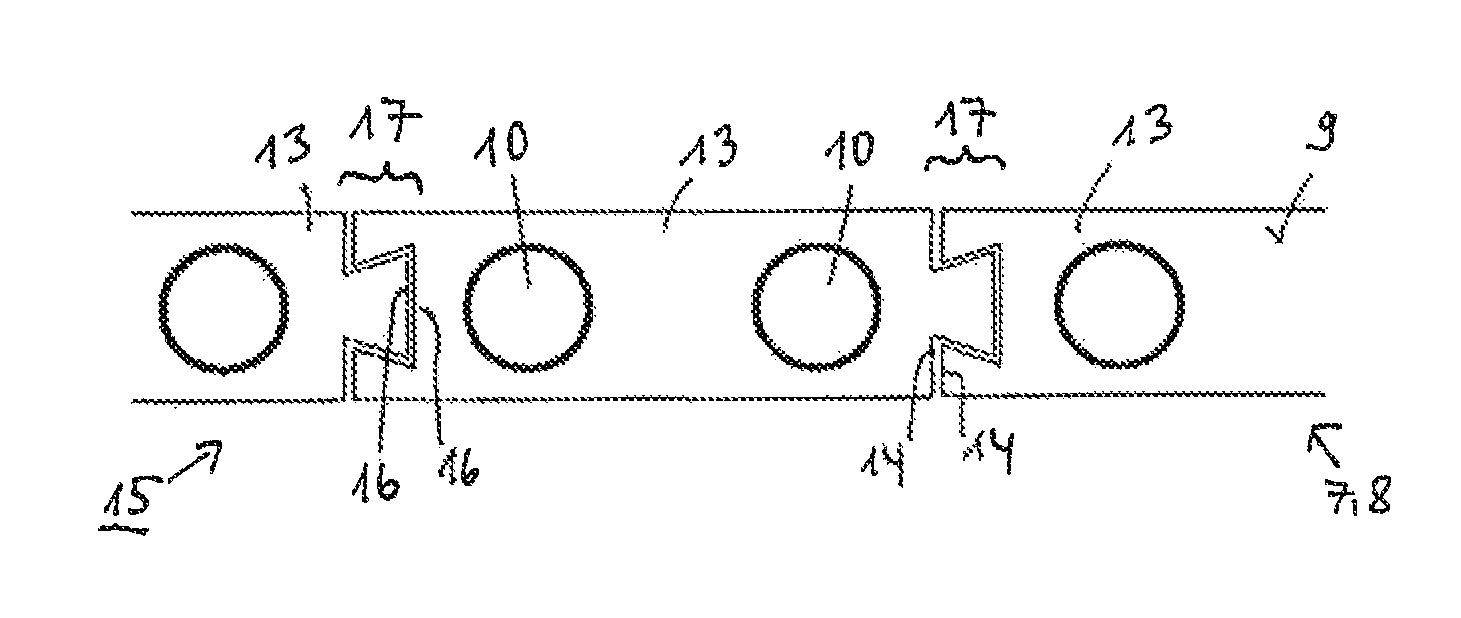

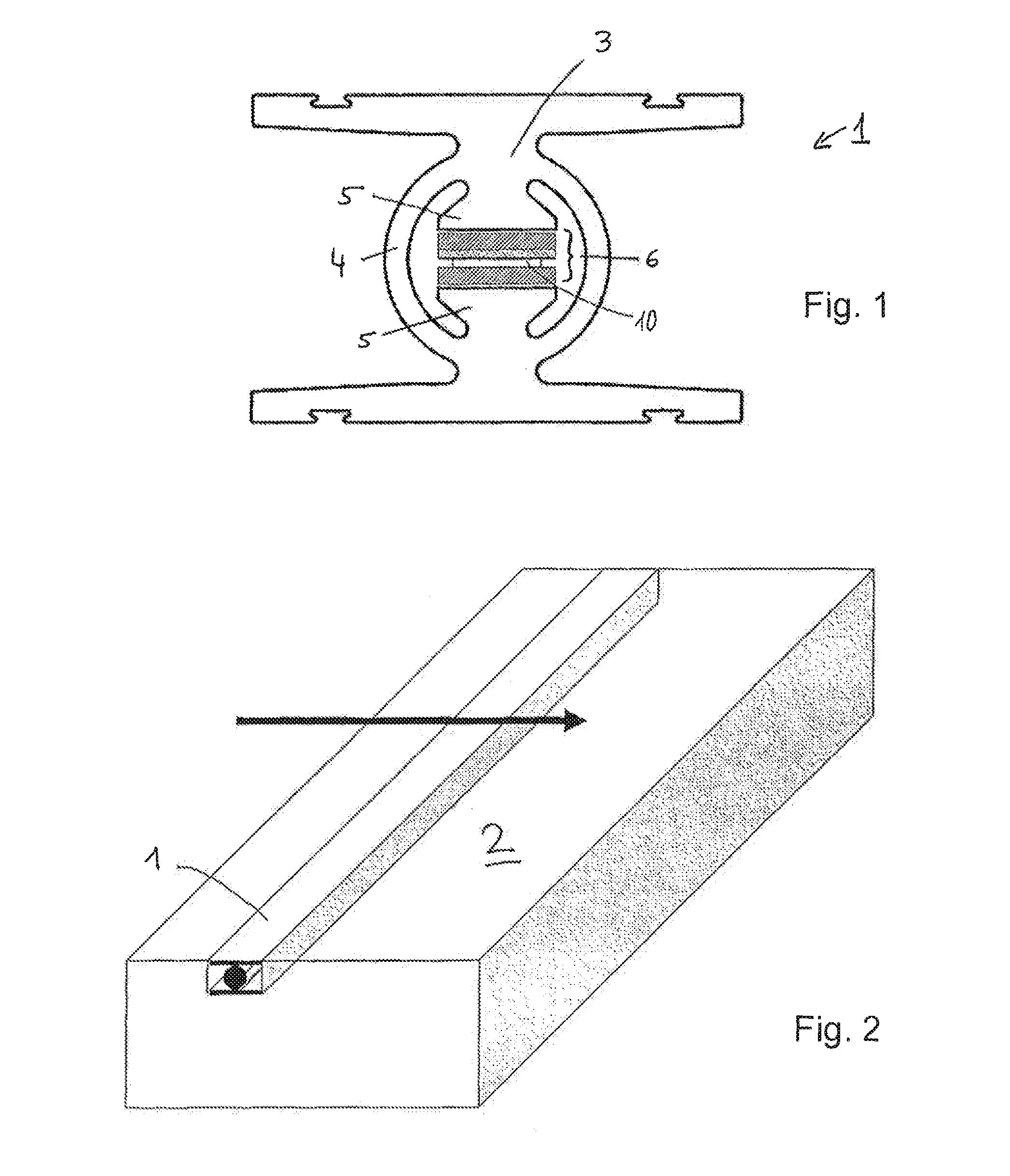

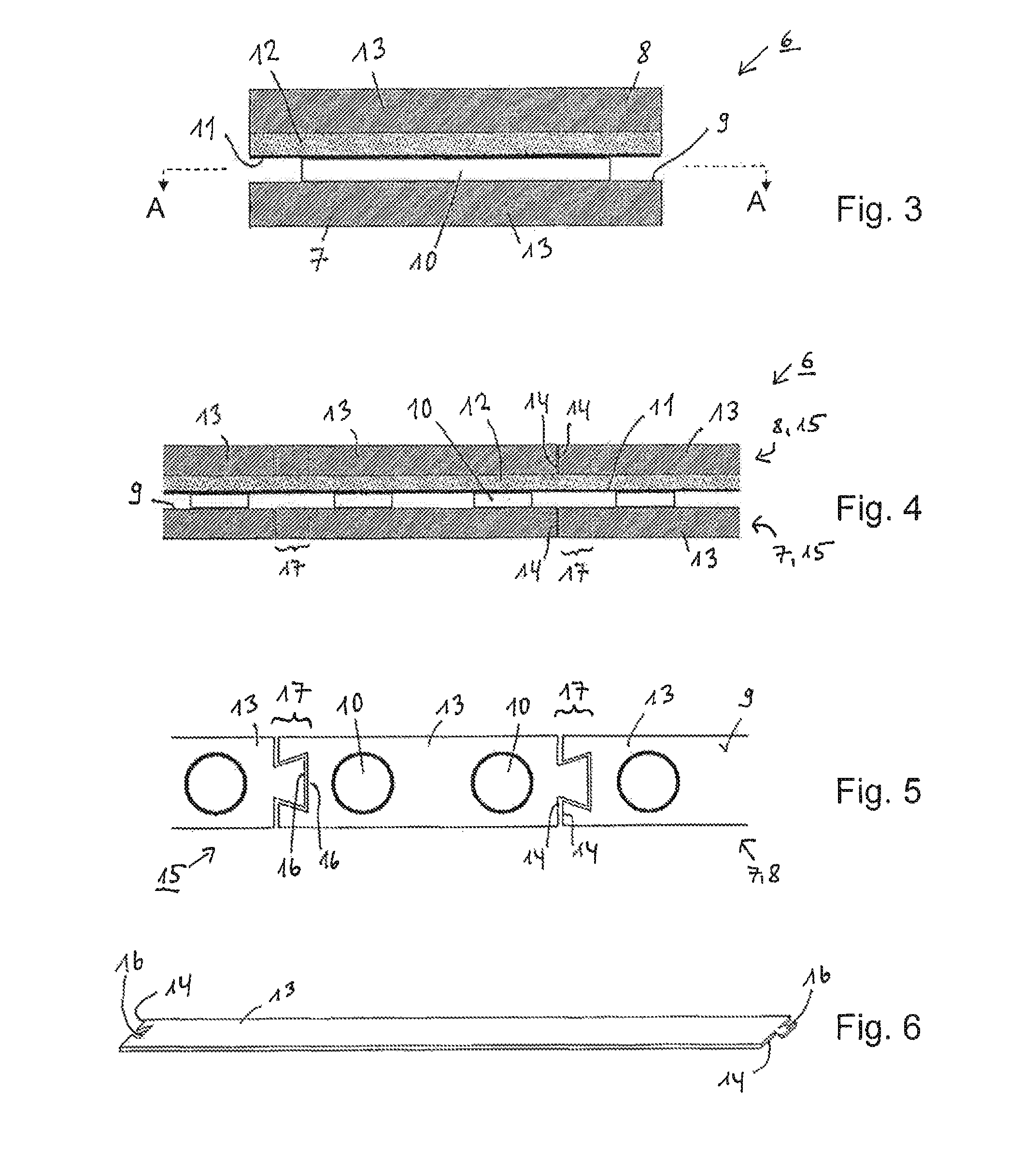

Sensor package for wim sensor and wim sensor

ActiveUS20140345955A1Flexibility in lengthReduce needWeighing apparatus using elastically-deformable membersWeighing apparatus detailsWeigh in motionElectrical and Electronics engineering

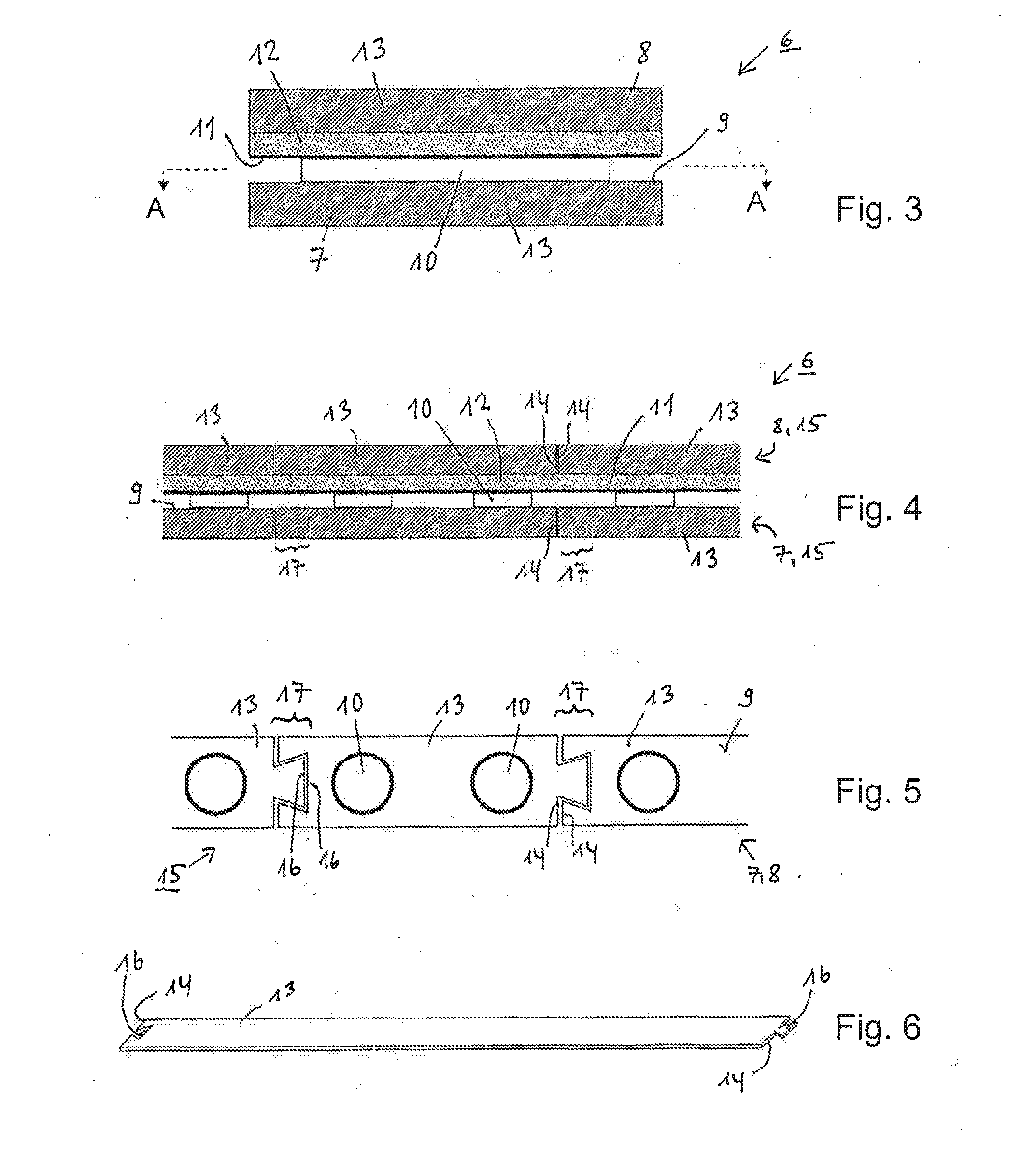

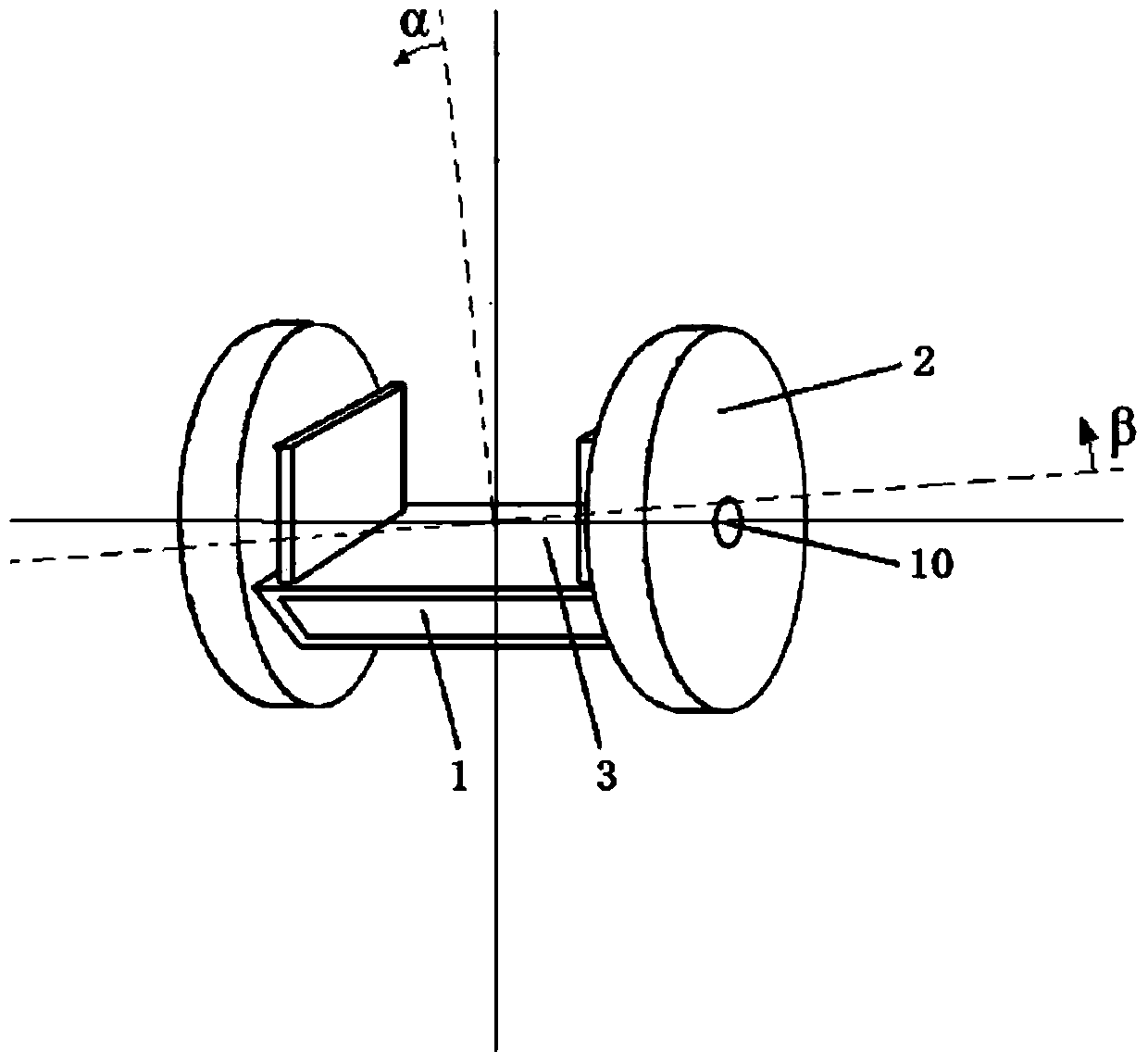

The invention relates to a sensor package (6) with long design for a WIM (Weigh in Motion) sensor (1), comprising a first receiving plate (7), a plurality of measuring elements (10), which are arranged equally spaced in a row (15) on the upper side (9) of the first receiving plate (7), an electrode (11) covering all the measuring elements (10), insulation (12) completely covering the electrode (11), and a second receiving plate (8), which covers the insulation (12). In particular, each receiving plate (7, 8) consists of a plurality of receiving elements (13) the end faces (14) of which are juxtaposed in a row (15). According to the invention, the inner end faces (14) of the receiving elements (13) of at least one row (15) have profiles (16) which engage in a form fit manner with the profiles (16) of the adjacent end faces (14) of neighbouring receiving elements (13). The invention further relates to a WIM sensor (1) comprising a hollow profile (3) with a tube (4) and two opposing mountings (5) arranged therein, between which a sensor package (6) according to the invention is arranged under initial tension.

Owner:KISTLER HLDG AG

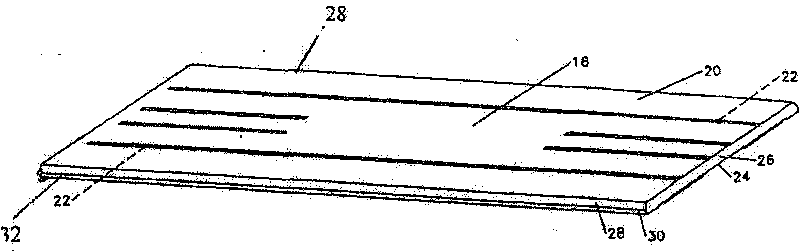

Weigh in motion technology

ActiveUS7423225B1Advanced technologyWeighing apparatus detailsSpecial purpose weighing apparatusEngineeringLoad cell

A weighing system has at least one weighing platform receiving a moving load to be weighed, the platform includes at least one scale member connected to at least two approach members, and including at least one ramp member connected to at least one of the approach members. An interface is communicatively connected to the scale member. A controller is connected to the interface. And, a power supply is connected to the interface. Also disclosed is a weighing scale having a rigid pad having a top surface for receiving the load and a bottom surface. A plurality of load cells are included, each having at least two top surfaces and at least two bottom surfaces. A top surface of each load cell is connected at a predetermined location to the bottom surface of the pad. A foot member contacts the ground and is connected to a bottom surface of the load cell. Further disclosed is a load cell having a body defined by first and second sides. The body has a peripheral region of a predetermined thickness and a central region of a predetermined thickness which is less than that of the peripheral region. The central region is inset on each side with respect to the peripheral region. The central region is adapted for contact with a force.

Owner:INTERCOMP

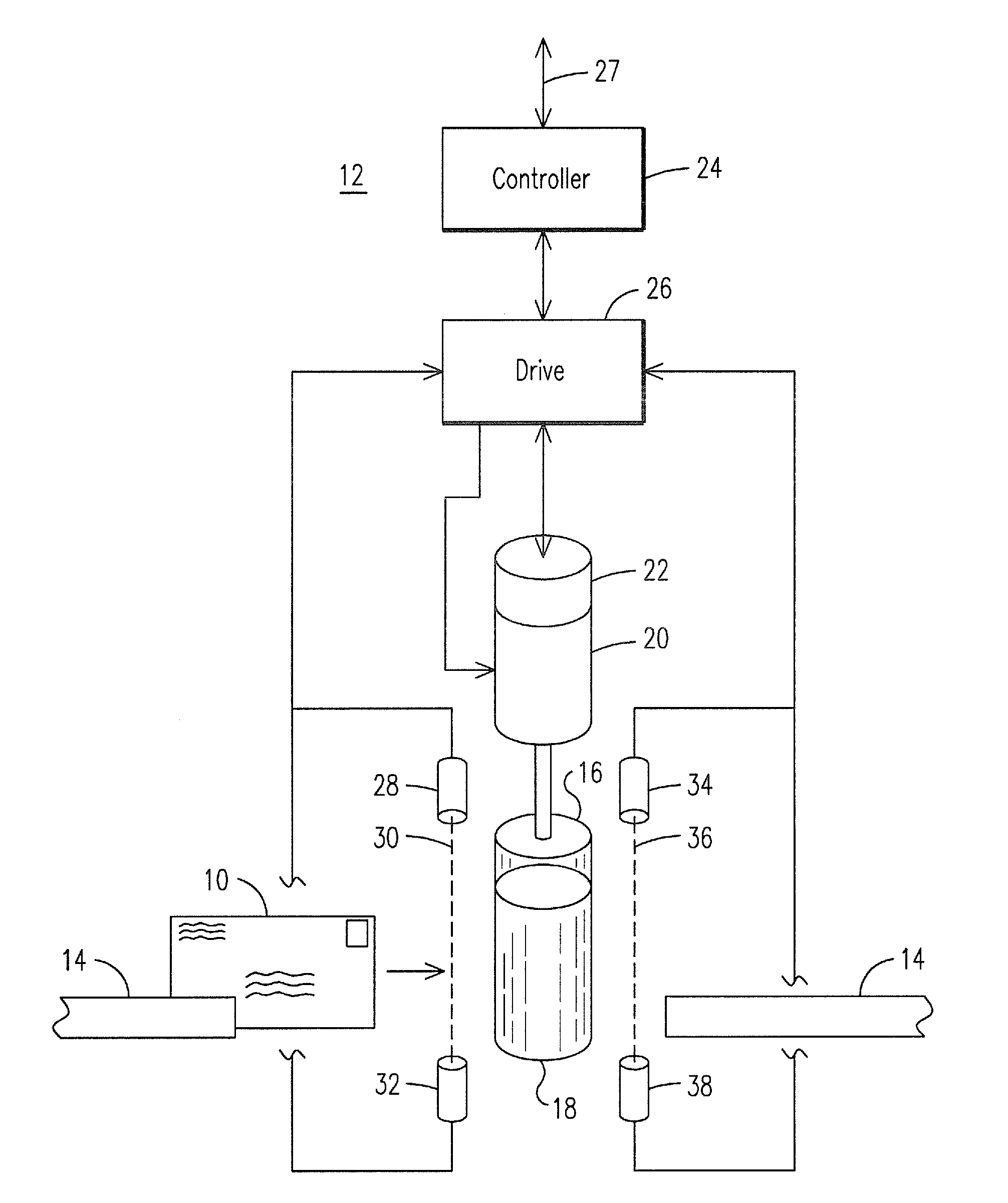

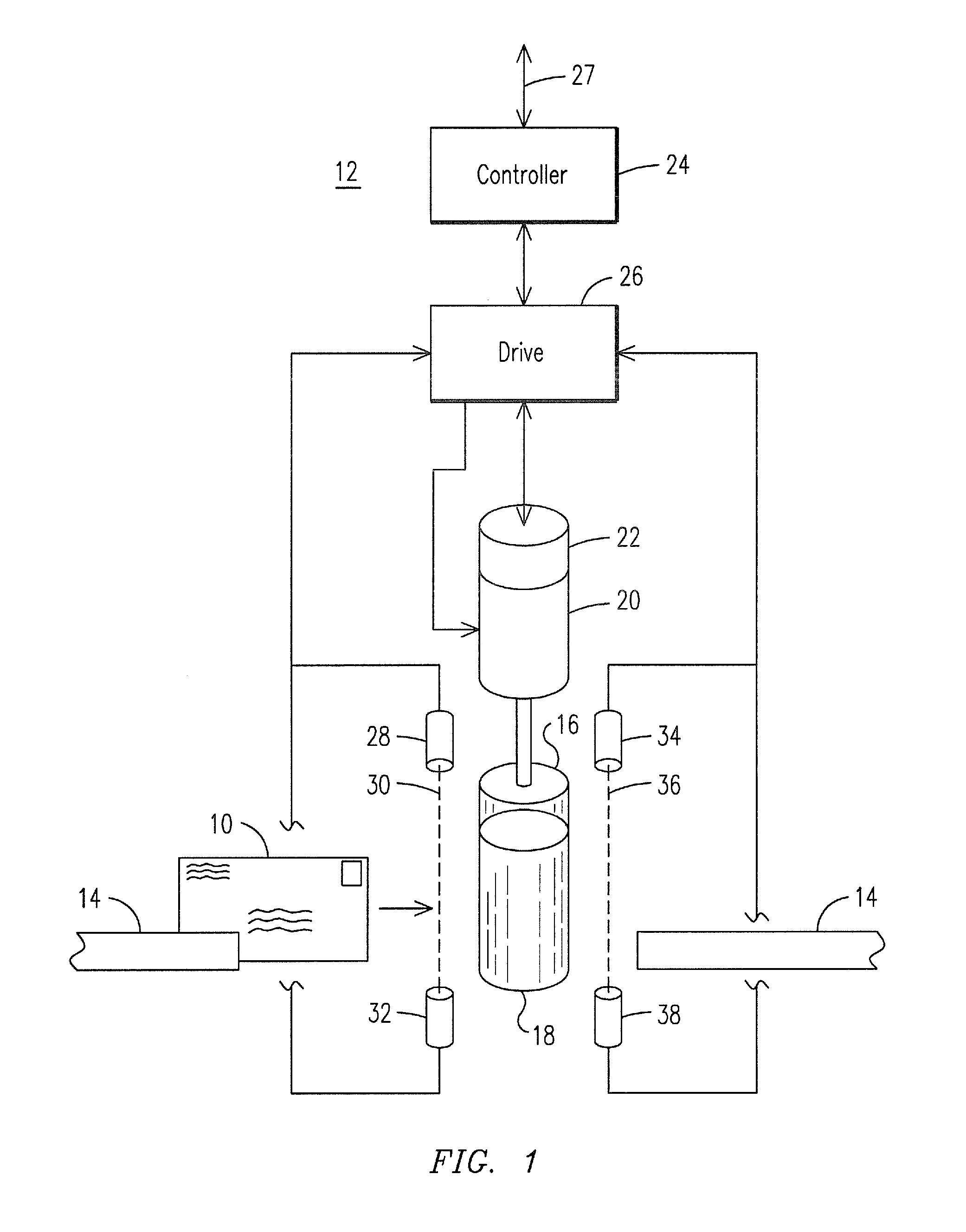

System for determining the mass of an item in motion

InactiveUS20090216487A1Weighing apparatus testing/calibrationDigital computer detailsElectric machineSoftware engineering

A method (51) for measuring the mass of an object such as a letter (10) in motion. An apparatus (12) for carrying out the present invention includes a pair of rollers (16, 18) through which a letter passes. One of the rollers (16) is driven by a motor (20) which has an associated encoder (22) to give motor positional information to a controller (24). In a method of the present invention the controller generates a ramping torque signal (44) which is provided to the motor. A friction correction curve (40) is generated and applied to the torque signal, and an average torque value (C) is determined. From the positional information provided by the encoder, acceleration (50) is derived and an inertia value is obtained by dividing the average torque (C) by the acceleration. Prior to obtaining an inertia value with a letter, an initial inertia value is obtained without a letter to get a base inertia. The base inertia is subtracted from the measured inertia with a letter to get a difference Δl. The mass (M) of the letter is obtained using the formula Δl=1 / 2M r2, where r is the radius of the driven roller.

Owner:MOTION ENG

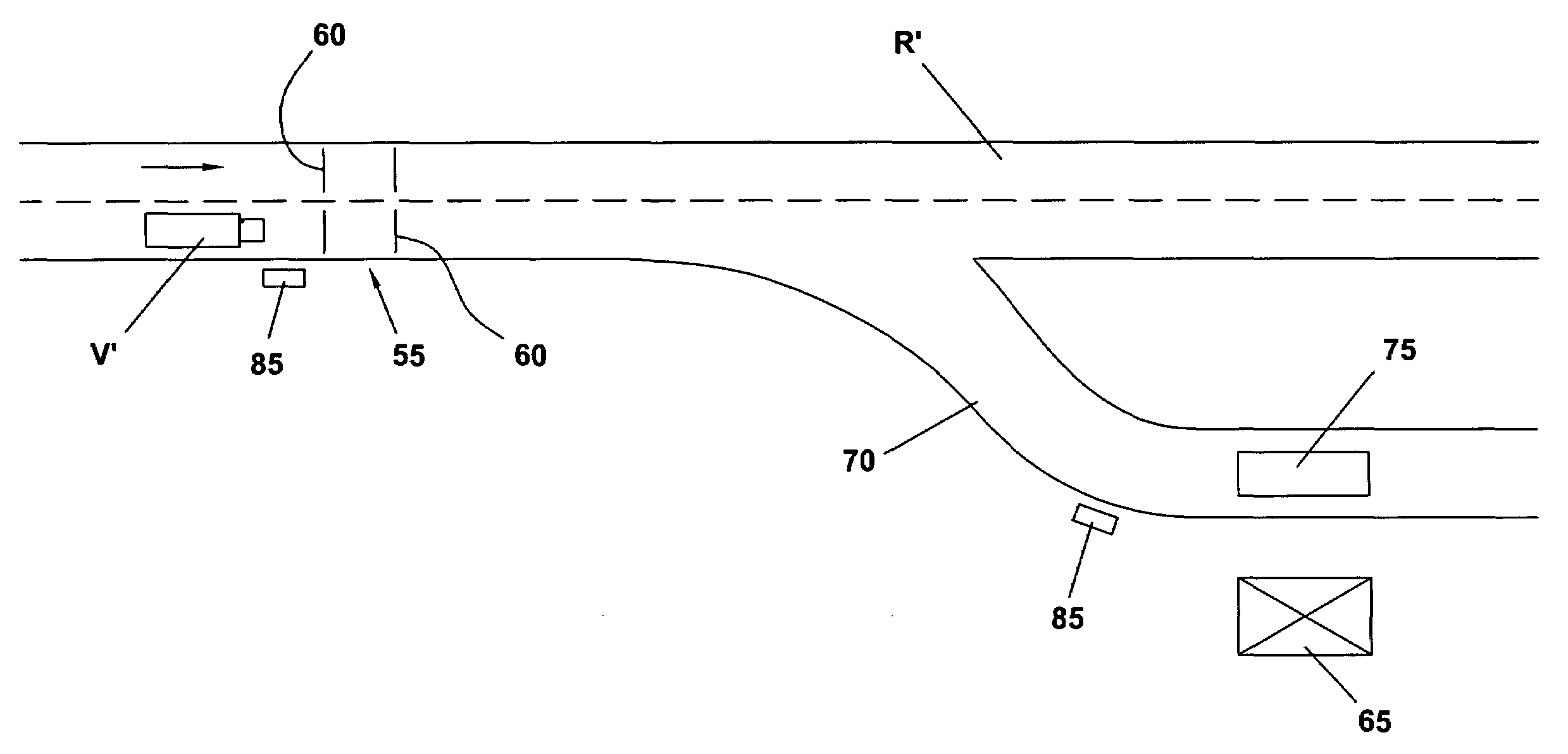

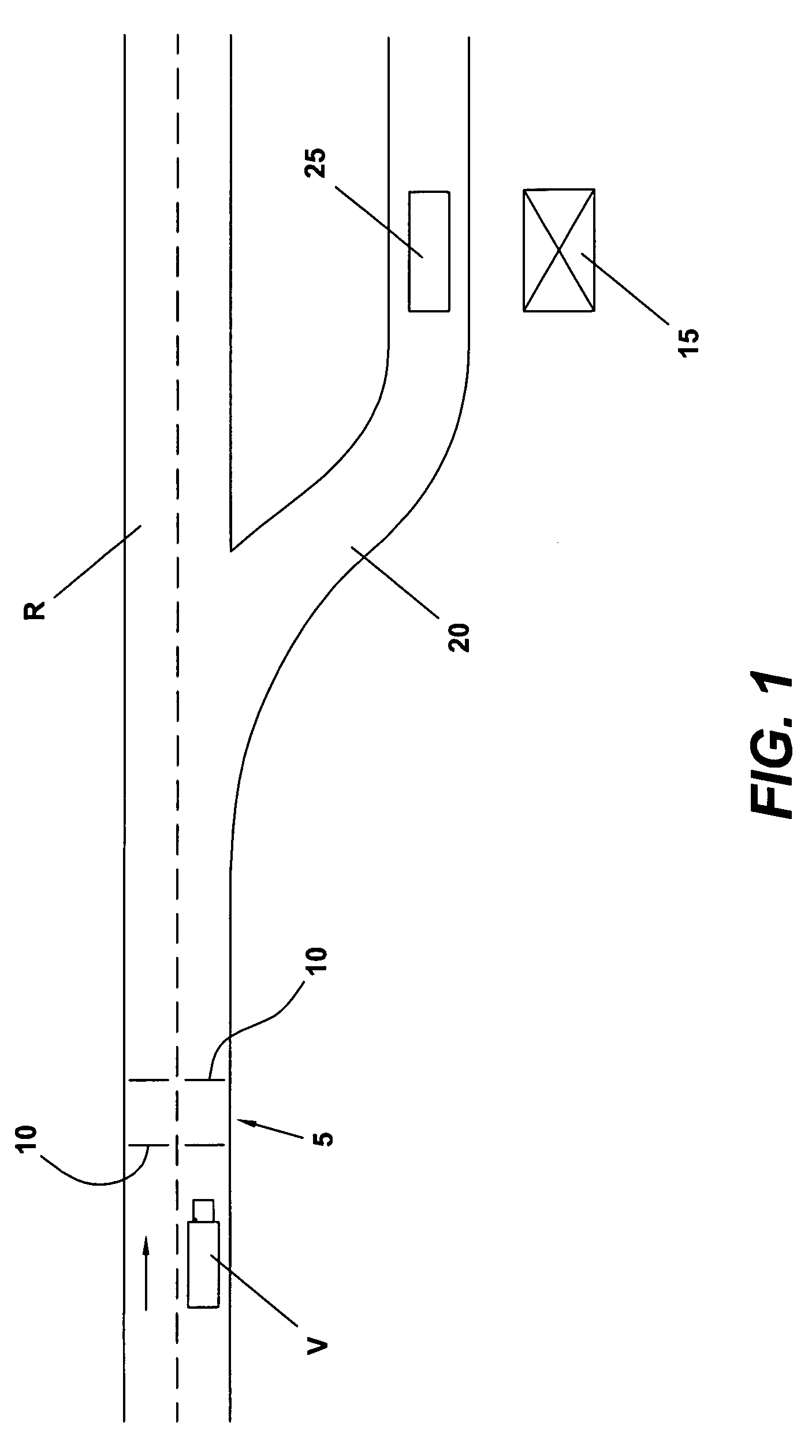

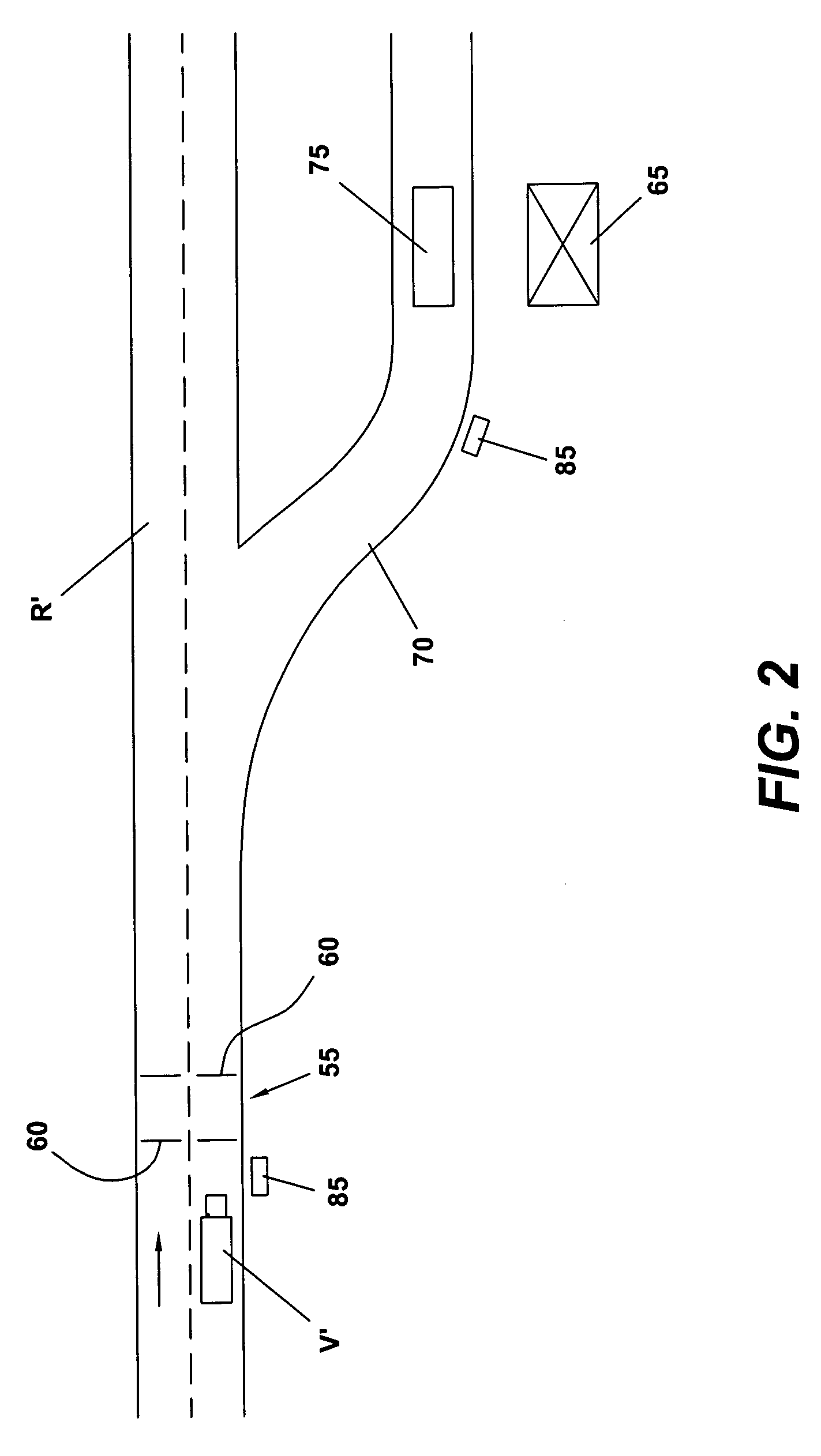

System and method for weighing and characterizing moving or stationary vehicles and cargo

InactiveUS20070067141A1Accurate measurementQuickly and accurately determineDigital computer detailsWeighing apparatus for materials with special property/formMicrocomputerMicrocontroller

Owner:UT BATTELLE LLC

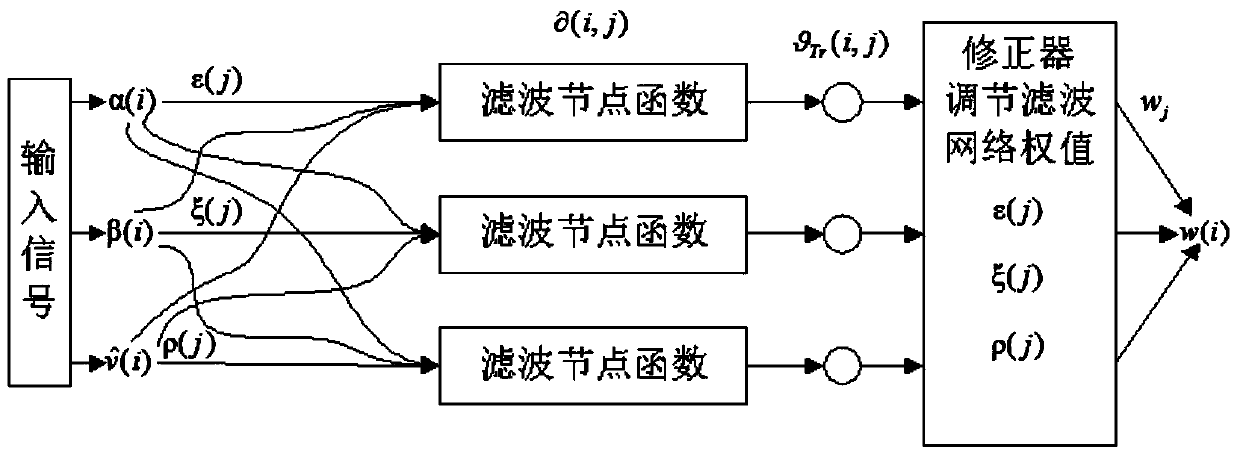

Self-balance control method of movable type inverted pendulum system and self-balance vehicle intelligent control system

InactiveCN103753557AImprove stabilityImprove reliabilityProgramme-controlled manipulatorMovable typeEquilibrium control

The invention discloses a self-balance control method of a movable type inverted pendulum system. State signals of the movable type inverted pendulum system are collected, the filter processing data method with the combination of a wavelet topology network and a regulator is adopted, a signal fusion technology is used for assistance, input data, middle data and output data of each filter node where effective values of the wavelet network enter are continuously adjusted, the controlled system control number output by the system is completed, the stability and the reliability of work of an inverted pendulum are improved, and the driving and riding stability, safety and comfort of an electric riding tool based on the inverted pendulum system are improved. The invention discloses a self-balance vehicle intelligent control system. By the adoption of a filter processing unit and a signal fusion unit, the capacity of combined control and information feedback of an electrical system and a mechanical system are improved, tiny disturbance generated in the movement process of a self-balance vehicle is reduced, the intelligent degree is improved, the self-balance vehicle intelligent control system is convenient and easy to use, comfortable, stable and capable of reducing cost and improving the cost performance.

Owner:SHANGHAI CHUANGHUI ROBOT TECH

Hollow profile for a weight-in-motion sensor

ActiveUS9304032B2Reduce sensitivityEasy to bendWeighing apparatus using elastically-deformable membersWeighing apparatus detailsEngineeringMechanical engineering

Owner:KISTLER HLDG AG

Weigh-in-motion system with auto-calibration

ActiveUS7684946B2Accurate readingWeighing apparatus testing/calibrationSpecial data processing applicationsMobile vehicleComputer science

Weigh-in-motion (WIM) systems for weighing moving vehicles, the systems having the ability to automatically determine and periodically apply calibration factors to WIM scale readings. Auto-calibration may include transferring both WIM and static weight readings for the same vehicle to a database, associating the weight readings, collecting a number of such weight readings, and analyzing the differences between the WIM and static weight readings to calculate WIM scale calibration factors. The calibration factors may be based on vehicle characteristics such as vehicle weight, vehicle class and / or vehicle speed at the WIM scale.

Owner:METTLER TOLEDO INC

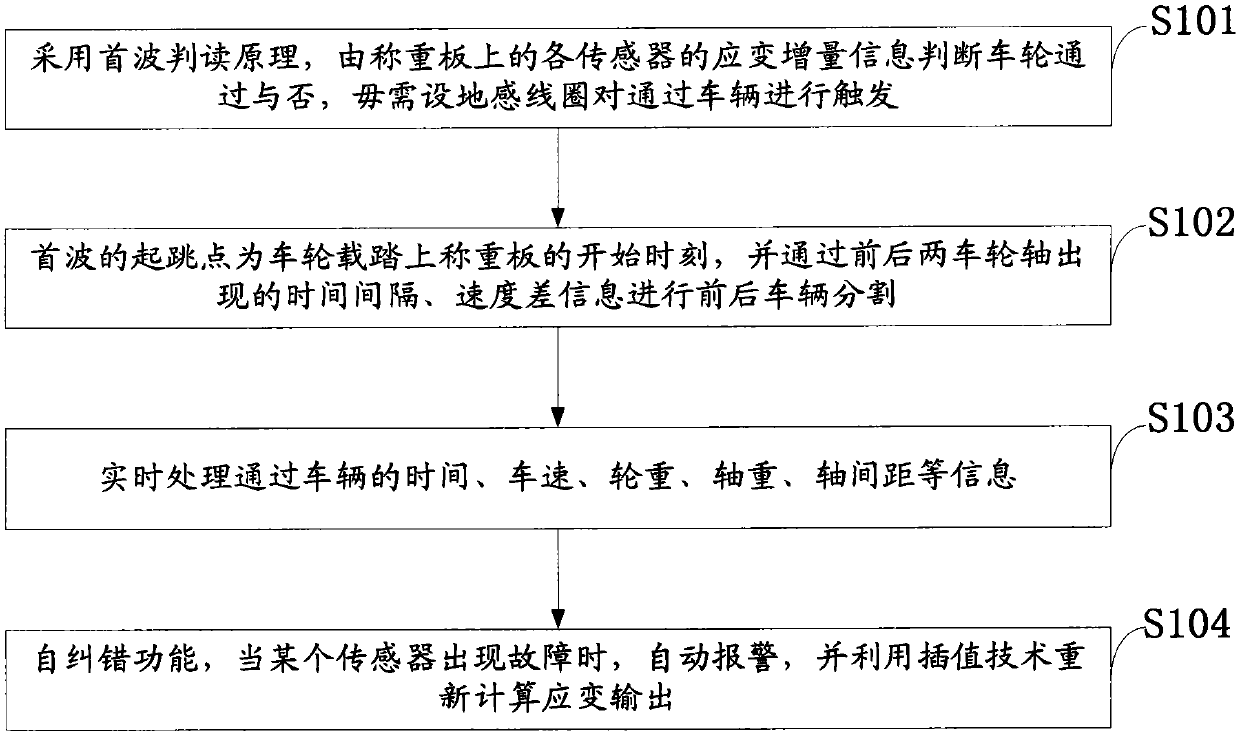

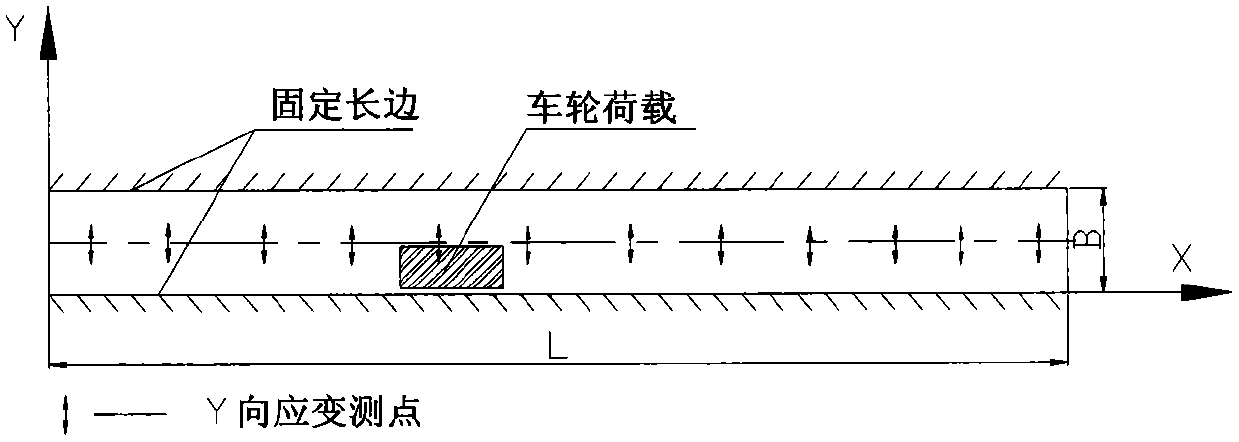

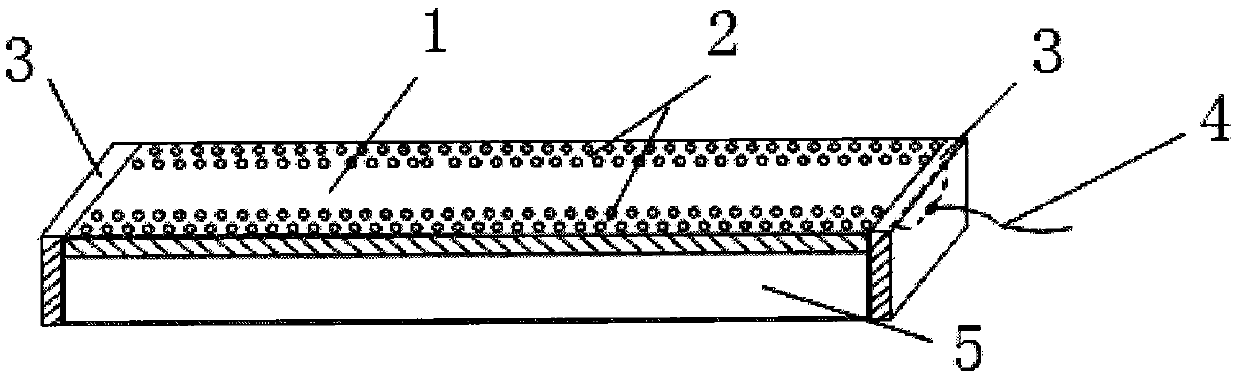

Weigh-in-motion method of high-speed and dynamic automobile based on optical fiber grating

InactiveCN103994809ASimple designImprove service levelWeighing apparatus using elastically-deformable membersSpecial purpose weighing apparatusStart timeGrating

The invention discloses a weigh-in-motion method of a high-speed and dynamic automobile based on an optical fiber grating. The weigh-in-motion method of the high-speed and dynamic automobile based on the optical fiber grating comprises the following steps of judging whether wheels pass or not by strain increment information of sensors on weigh plates by adopting a head wave interpretation principle, not needing to place a ground induction coil to trigger a passing vehicle, taking head wave start points as start time of the wheels loading on the weigh plates, distinguishing front and back vehicles by time interval and speed difference information of front and back axles, processing time, speed, wheel load, axle load and axle spacing information of the passing vehicle in real time, automatically alarming when some sensor has a fault, and computing a strain output again by utilizing an interpolation technique. According to the weigh-in-motion method, an error of the single wheel load is plus-minus 25%; an error of the gross vehicle weight is 10%; the maximum single wheel load is 150kN; and the weigh-in-motion method combines the traditional plate bending weigh-in-motion method and an excellent optical fiber sensing technique, so that the weigh-in-motion method has certain advancement and a practical application value.

Owner:王强

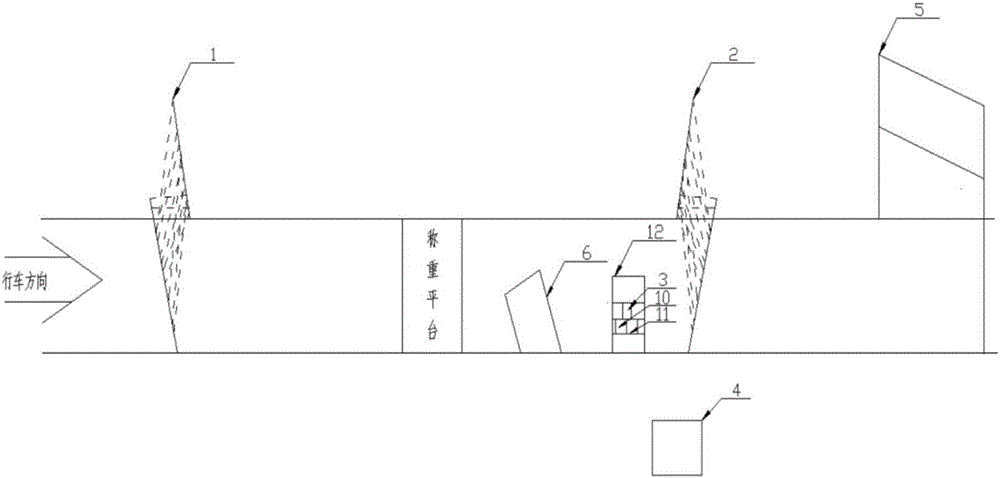

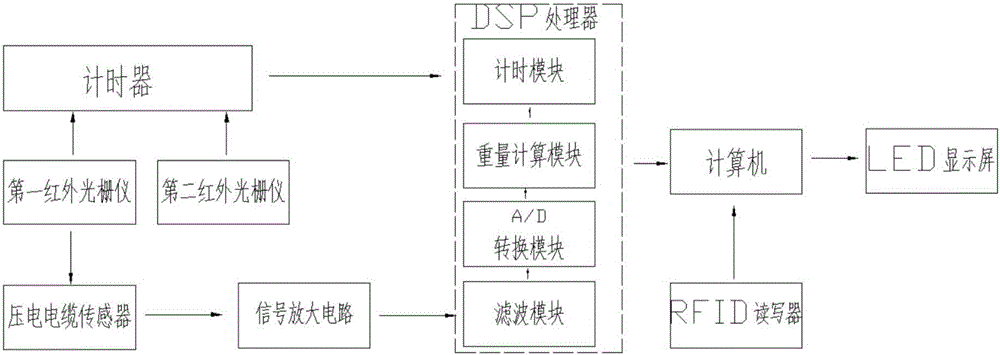

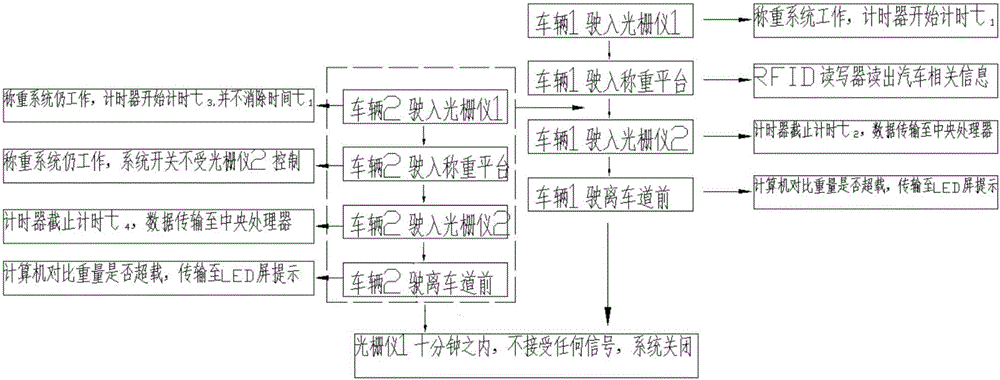

Automobile overload non-stop detection system and detection method based on RFID

ActiveCN106017621AReduce damageAccurate weightProgramme controlWeighing apparatus using elastically-deformable membersRoad surfaceTimer

The invention provides an automobile overload non-stop detection system and detection method based on RFID. The system includes a piezoelectric cable sensor, two groups of infrared grating instruments, an RFID reader, an RFID label, a computer, a DSP processor, a signal amplification circuit, a timer, and an LED display screen. A weigh-in-motion system is composed of the piezoelectric cable sensor, the signal amplification circuit, and the DSP processor, the dynamic weighing system is connected with the computer, the timer is connected with the infrared grating instruments, the infrared grating instruments are connected with the piezoelectric sensor, the RFID reader is connected with the computer, the RFID label is arranged on an automobile, and the computer is connected with the LED display screen. The weigh-in-motion system measures the weight signal during the automobile driving process and performs data processing; the timer records the automobile driving time; and the infrared grating instruments eliminate vehicle following phenomenon and are taken as the switch of the weigh-in-motion system. The system has the characteristics of high measurement precision, less damage to the pavement, and high adaptability.

Owner:江苏星火汽车部件制造有限公司

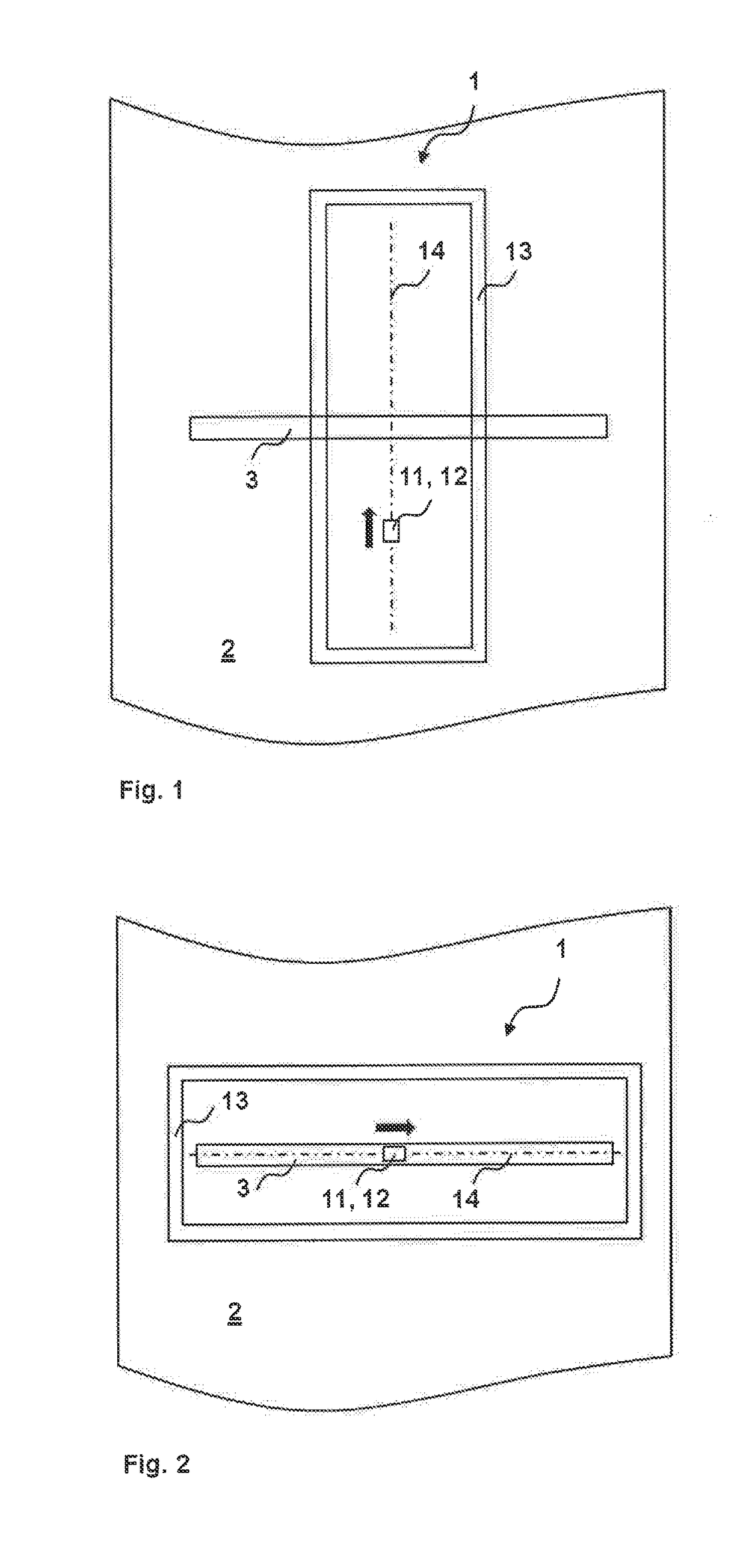

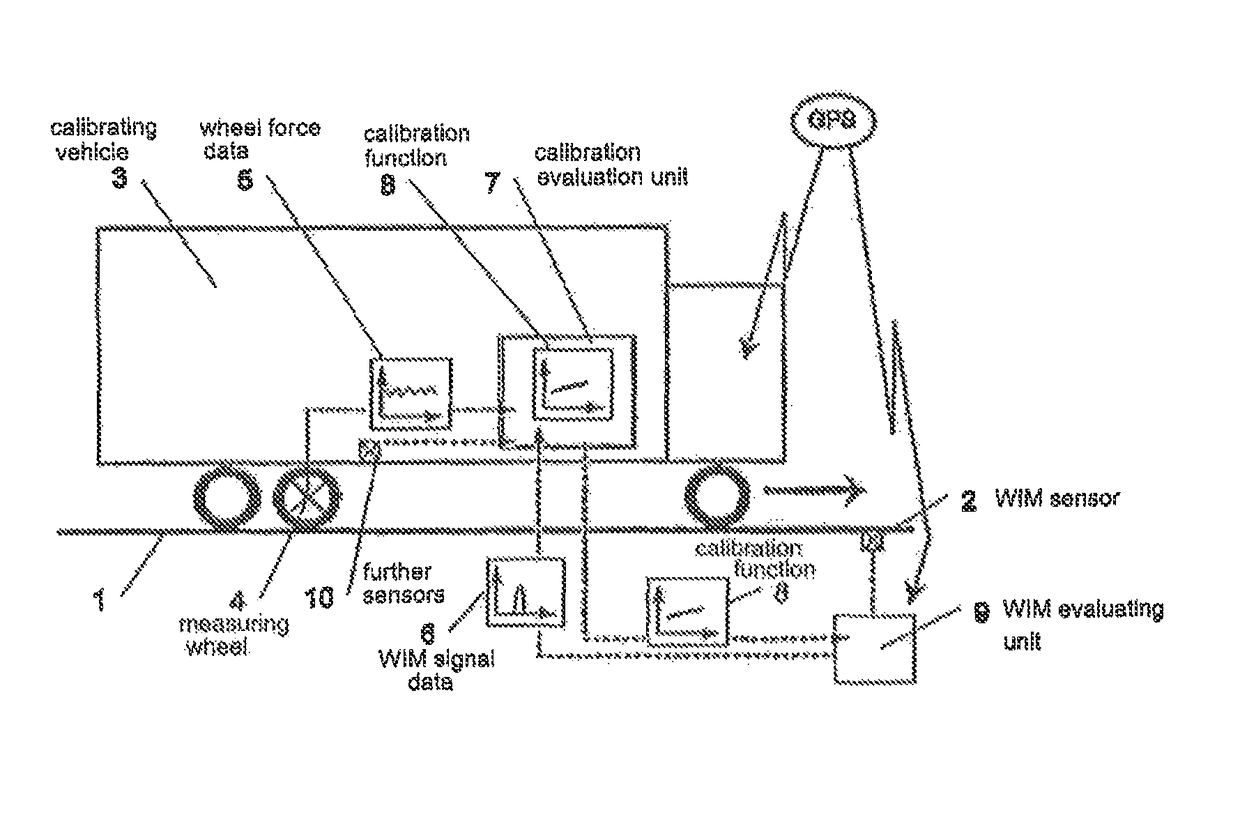

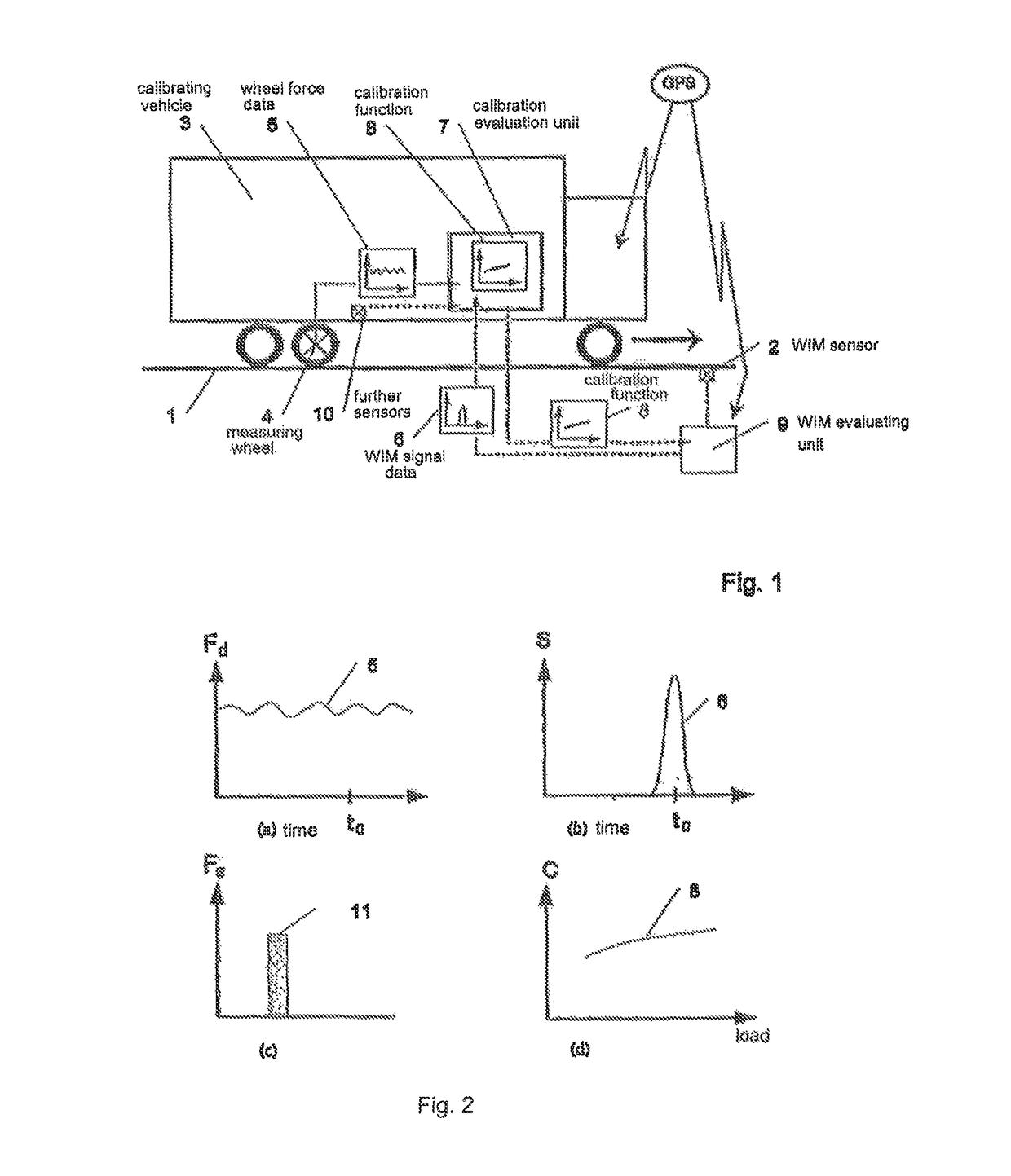

Method for calibrating wim-sensors

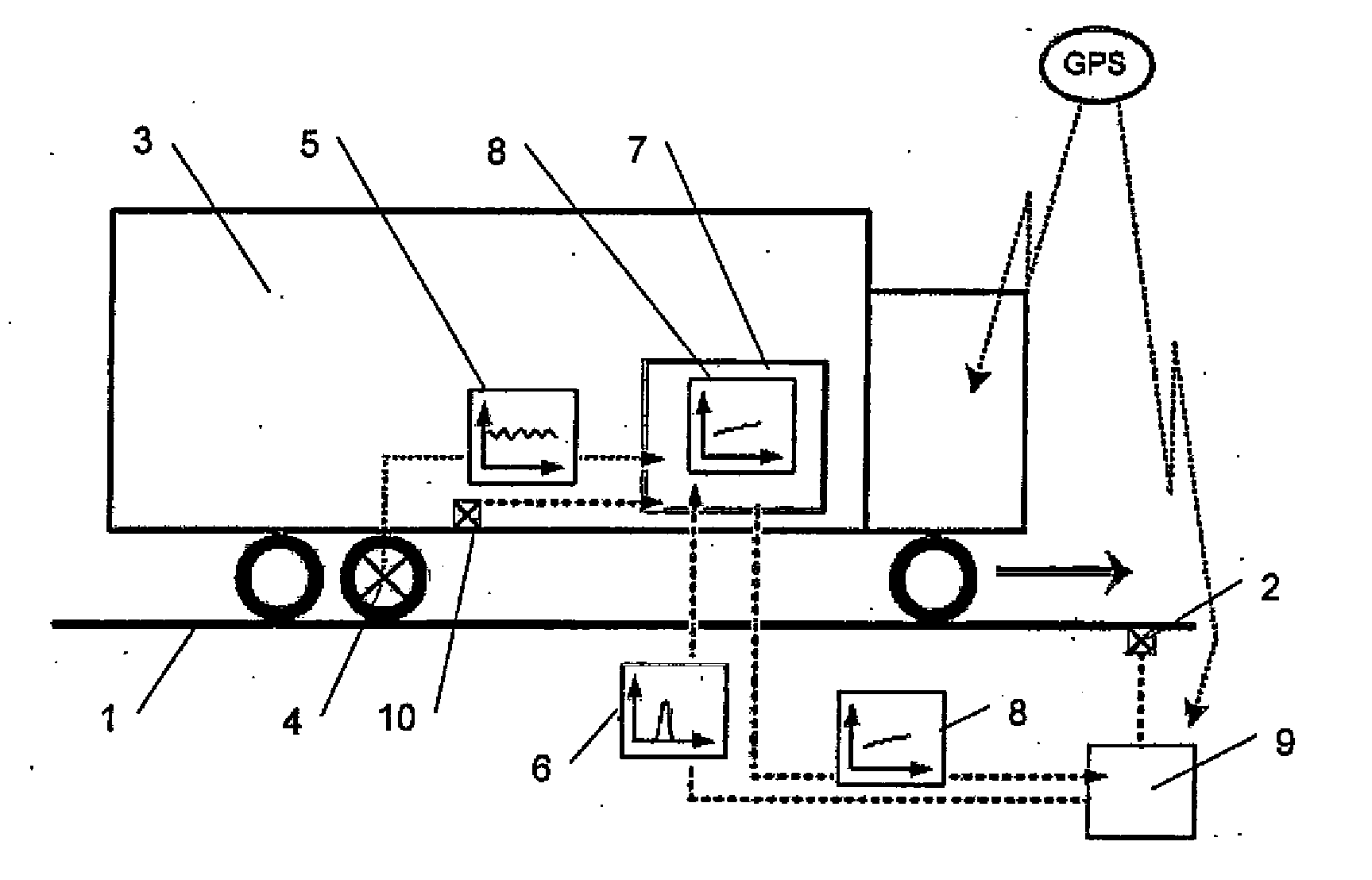

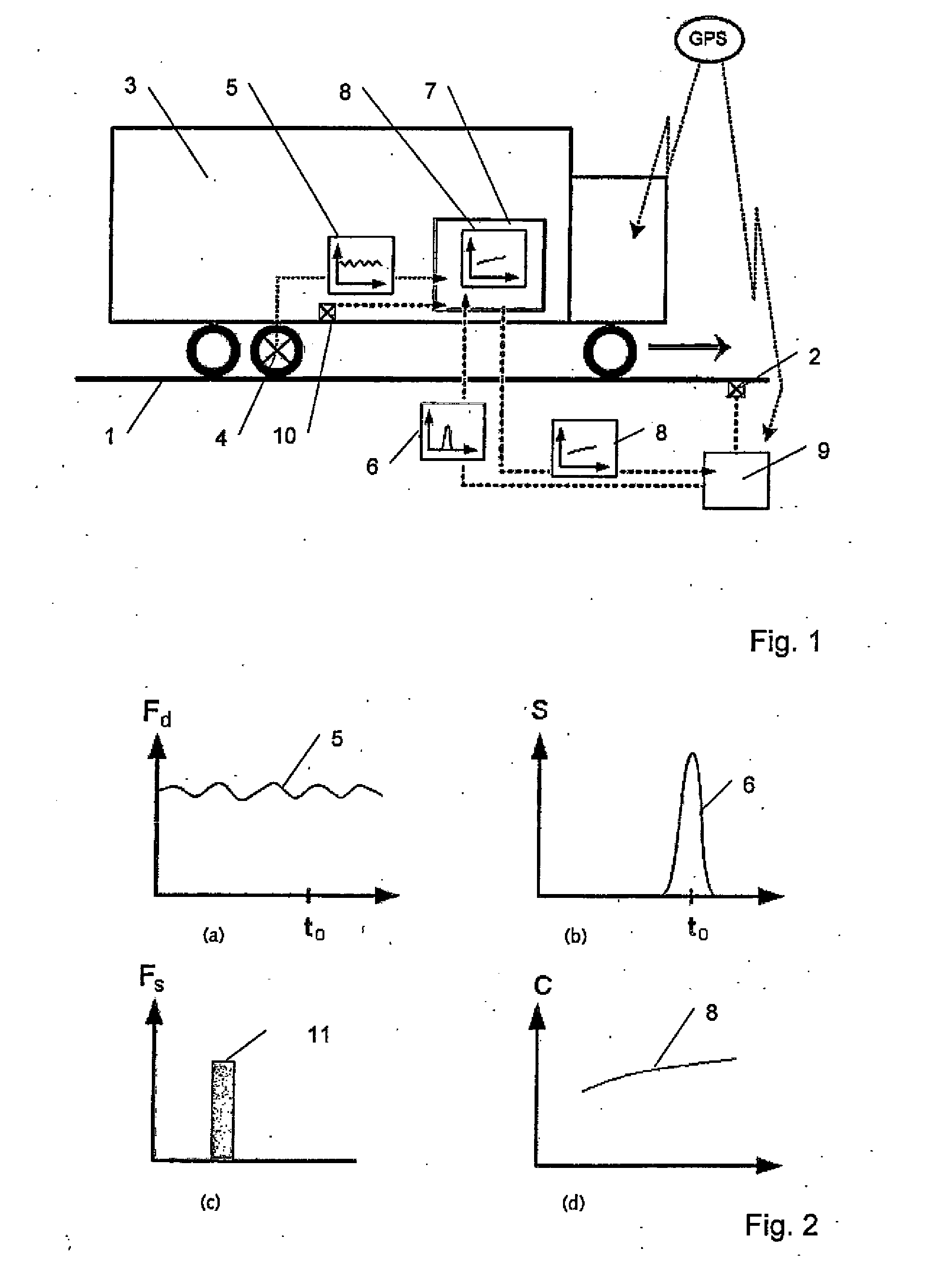

ActiveUS20130024152A1Weighing apparatus testing/calibrationSpecial data processing applicationsData synchronizationEngineering

A method for calibrating a WIM (Weigh in Motion) sensor built into a road during travel of a calibrating vehicle measures the dynamic wheel force on the road and on the WIM sensor directly at the measuring wheel, depending on time or location. These wheel force data are transmitted to an evaluating unit. As the calibrating vehicle passes over, WIM signal data are simultaneously measured at the WIM sensor and transmitted to the evaluating unit. The wheel force data are synchronised with the WIM signal data in the evaluating unit. A calibration function is determined by comparing the dynamic wheel force data with the WIM signal data.

Owner:KISTLER HLDG AG

Measurement of wheel and/or axle load of road vehicles

ActiveCN101738244AWeighing apparatus using elastically-deformable membersSpecial purpose weighing apparatusElectrical resistance and conductanceThin slab

Owner:INTERNATIONAL ROAD DYNAMICS

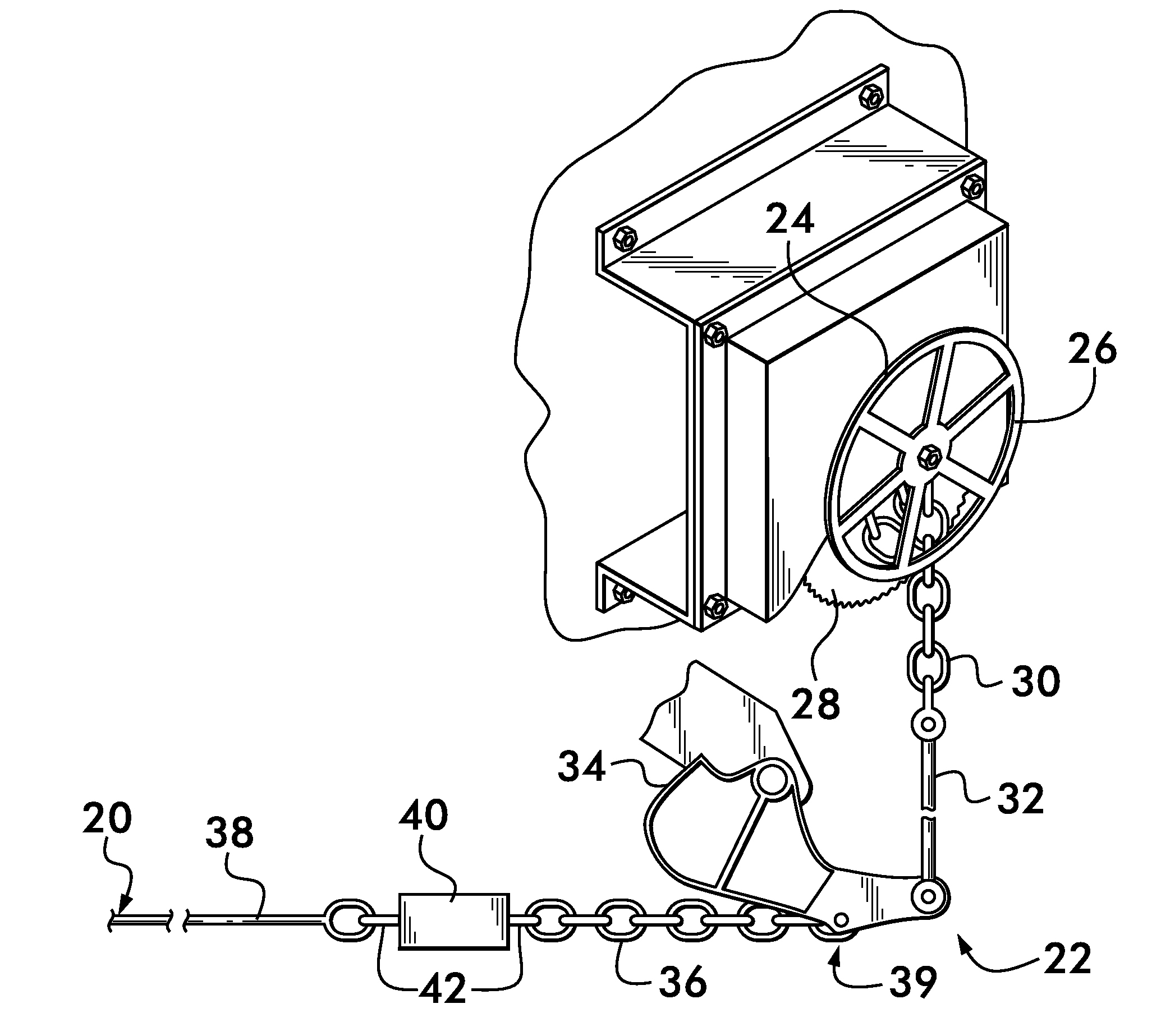

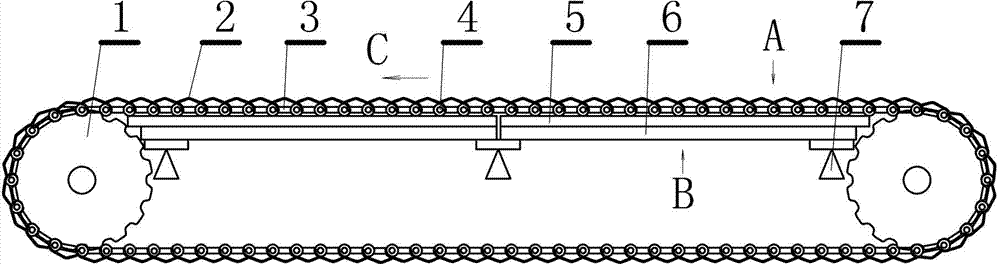

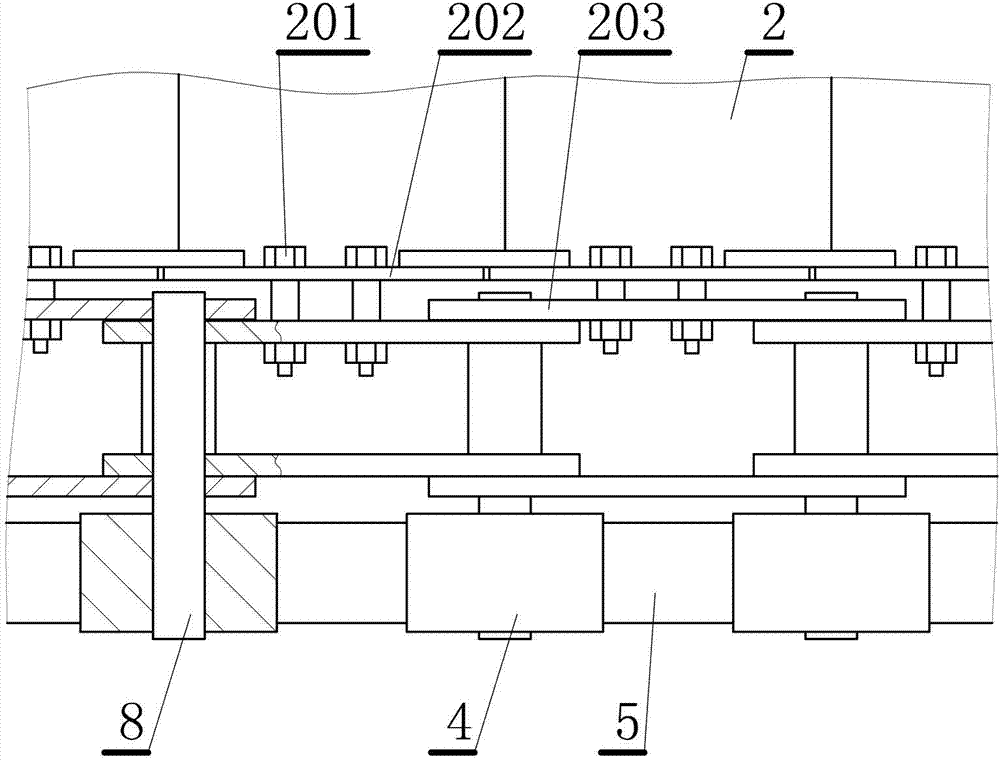

Weighing method and device of rapid quantitative plate conveyer

ActiveCN104291064ALower the altitudeSimplify shipping proceduresConveyorsControl devices for conveyorsClassical mechanicsEngineering

The invention relates to a weighing method and device of a rapid quantitative plate conveyer. The device comprises a chain wheel and a chain of the plate conveyer. A short shaft with the rotating axis perpendicular to the movement direction of the chain is arranged on each chain section of the chain. A wheel is arranged on each short shaft. The wheels on the two sides of the chain run on one or more guide rails on the left side and the right side of the chain respectively. The guide rails on the left side and the right side are installed on weighing platforms respectively, wherein the number of the guide rails is equal to the number of the weighing platforms. A plurality of weighing sensors are arranged below each weighing platform. Through the guide rails, the weights, dispersed on all bearing plates, of bulb materials are concentrated on the guide rails, the weights on the guide rails are then concentrated on the weighing platforms, the weights flat spread and accumulated on the bearing plates of the conveyer are concentrated under the common effect of the wheels, the guide rails and weighing racks so that the bulk materials can be weighed in the movement. According to the method and device, the weighing function and the conveying function of the plate conveyer are achieved, and the method and device play a very key role in reducing the height of a chamber and reducing the cost.

Owner:TIANDI SCI & TECH CO LTD

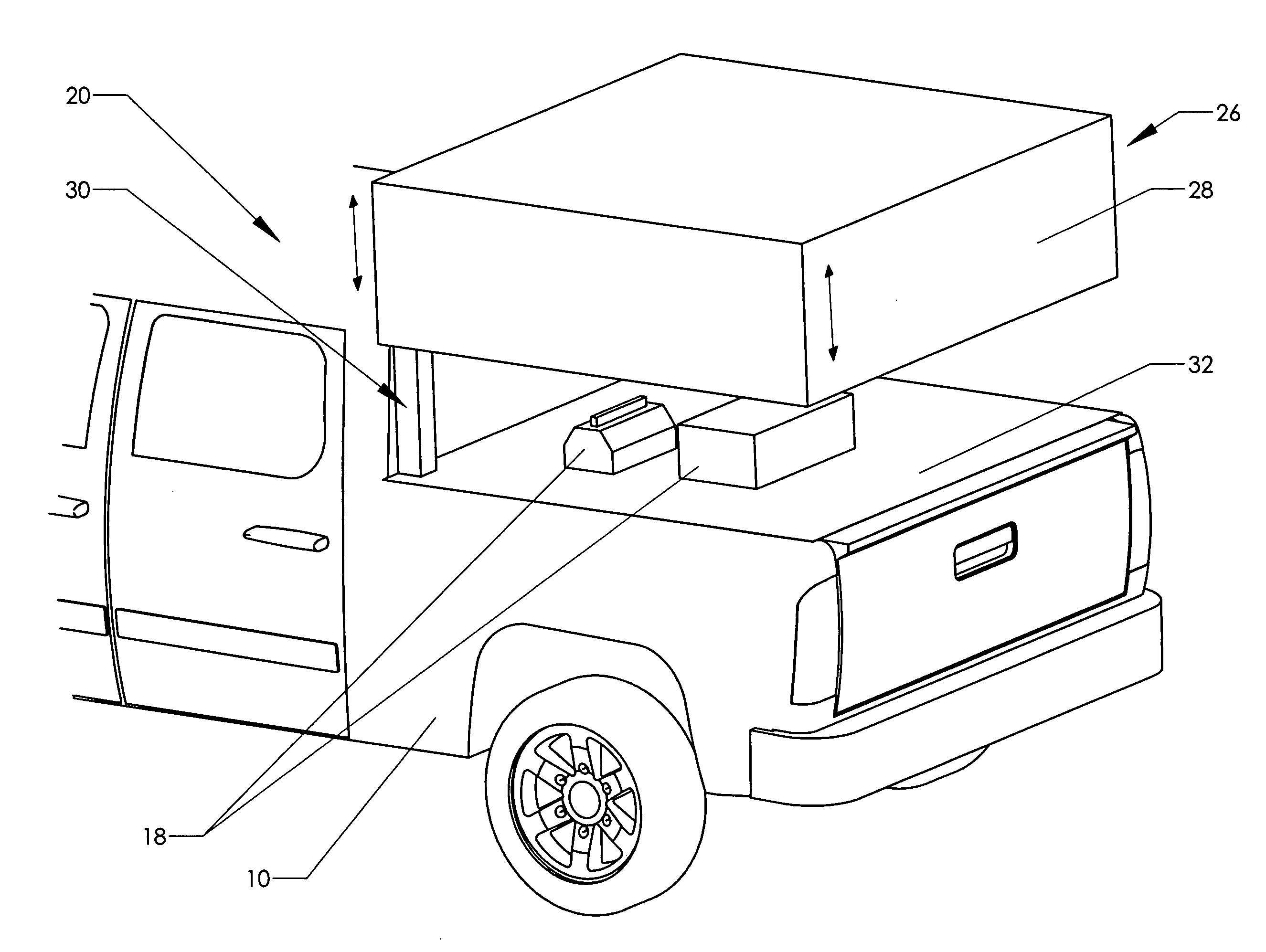

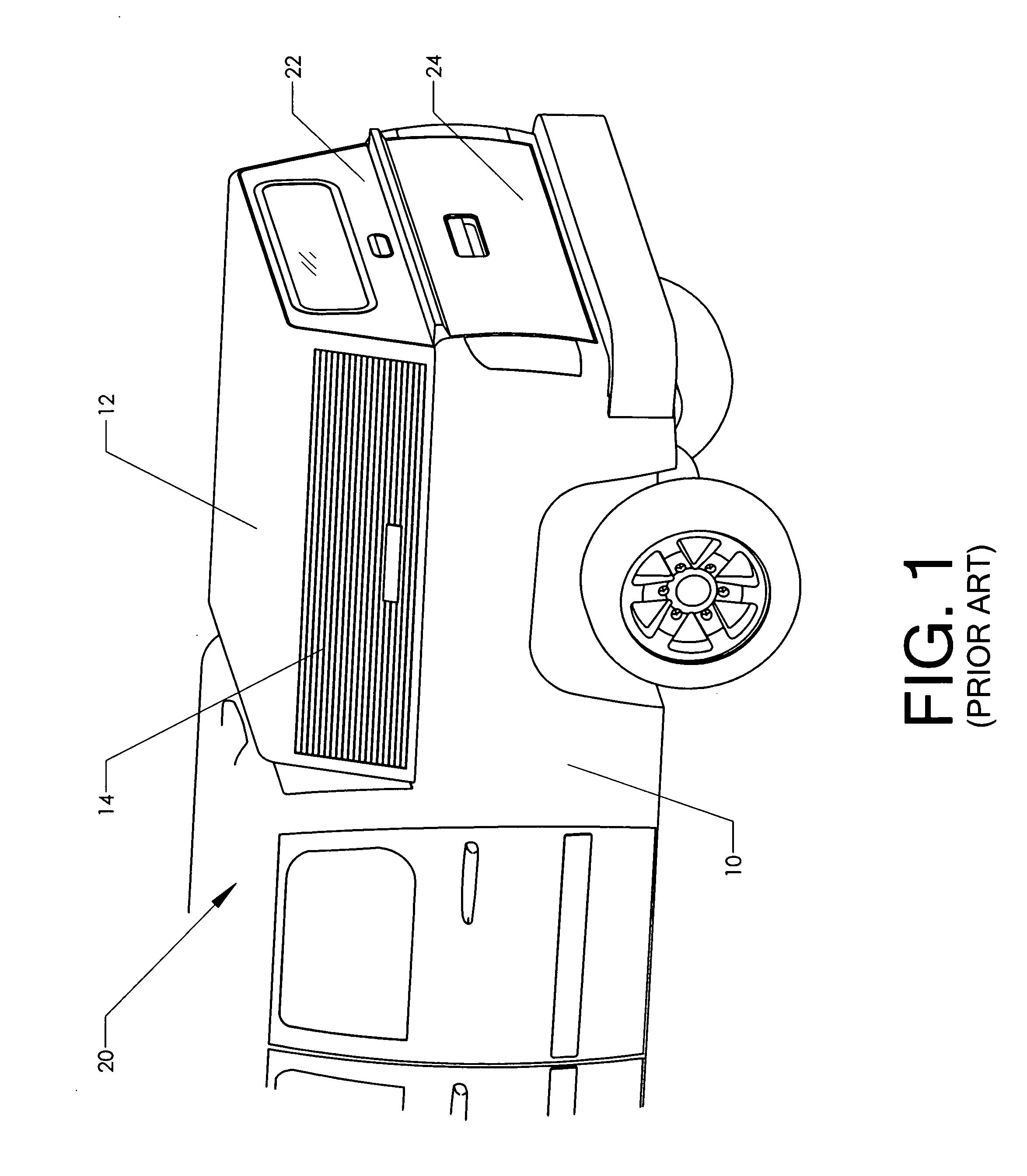

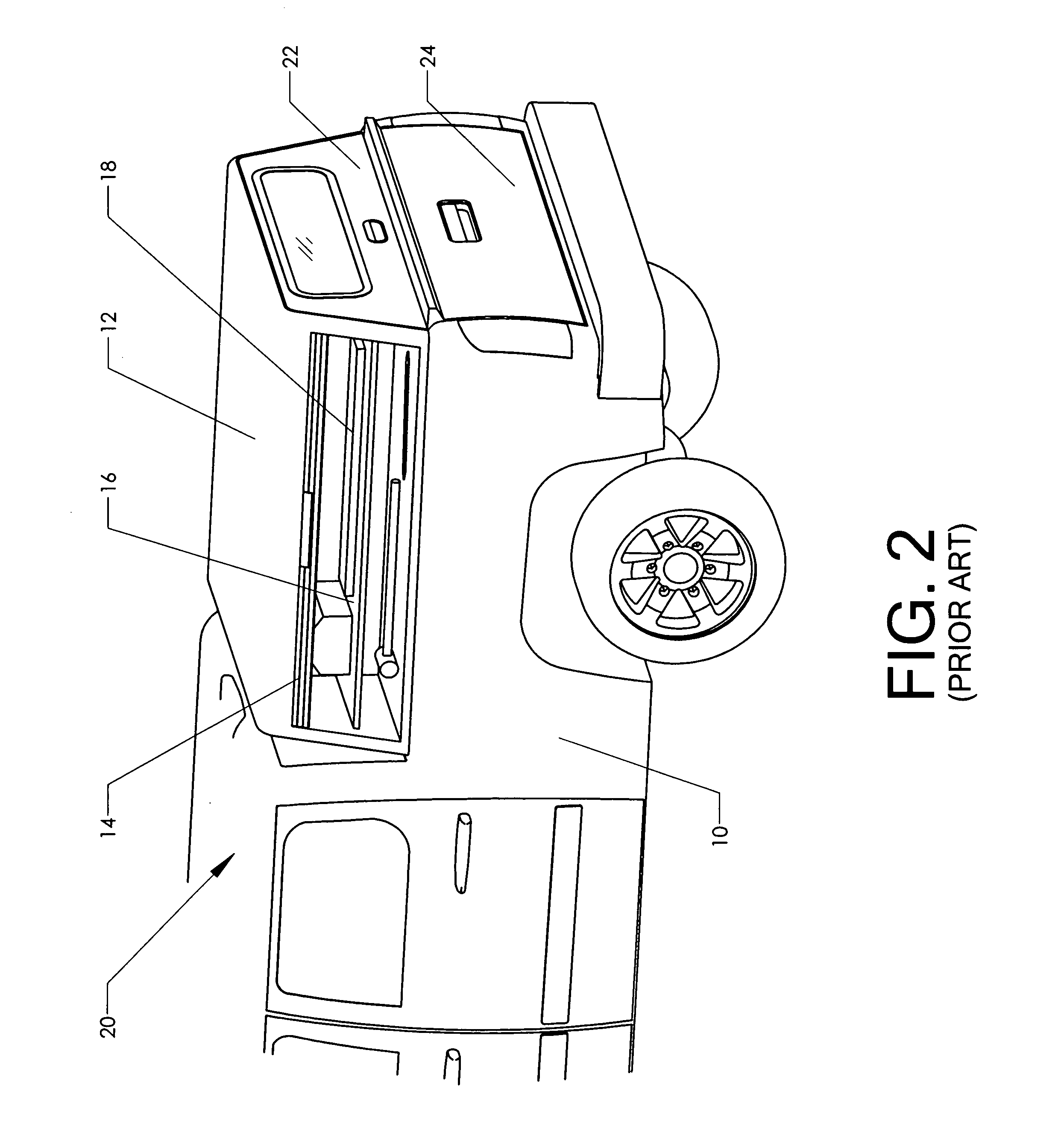

Truck bed cap

InactiveUS20110095559A1Easy accessSuperstructure subunitsItem transportation vehiclesEngineeringTruck

The present truck bed cap consists of an internal frame having a first shelf, a second shelf and a top, wherein the internal frame is connected to corner supports attached to the bed of the truck. In a first motion the top shifts vertically with respect to the internal frame. In a second motion the internal frame shifts vertically with respect to the corner supports and the bed of the truck.

Owner:EDENS DAVID

Sensor package for WIM sensor and WIM sensor

ActiveUS9372110B2Flexibility in lengthReduce needWeighing apparatus using elastically-deformable membersWeighing apparatus detailsEngineeringWeigh in motion

Owner:KISTLER HLDG AG

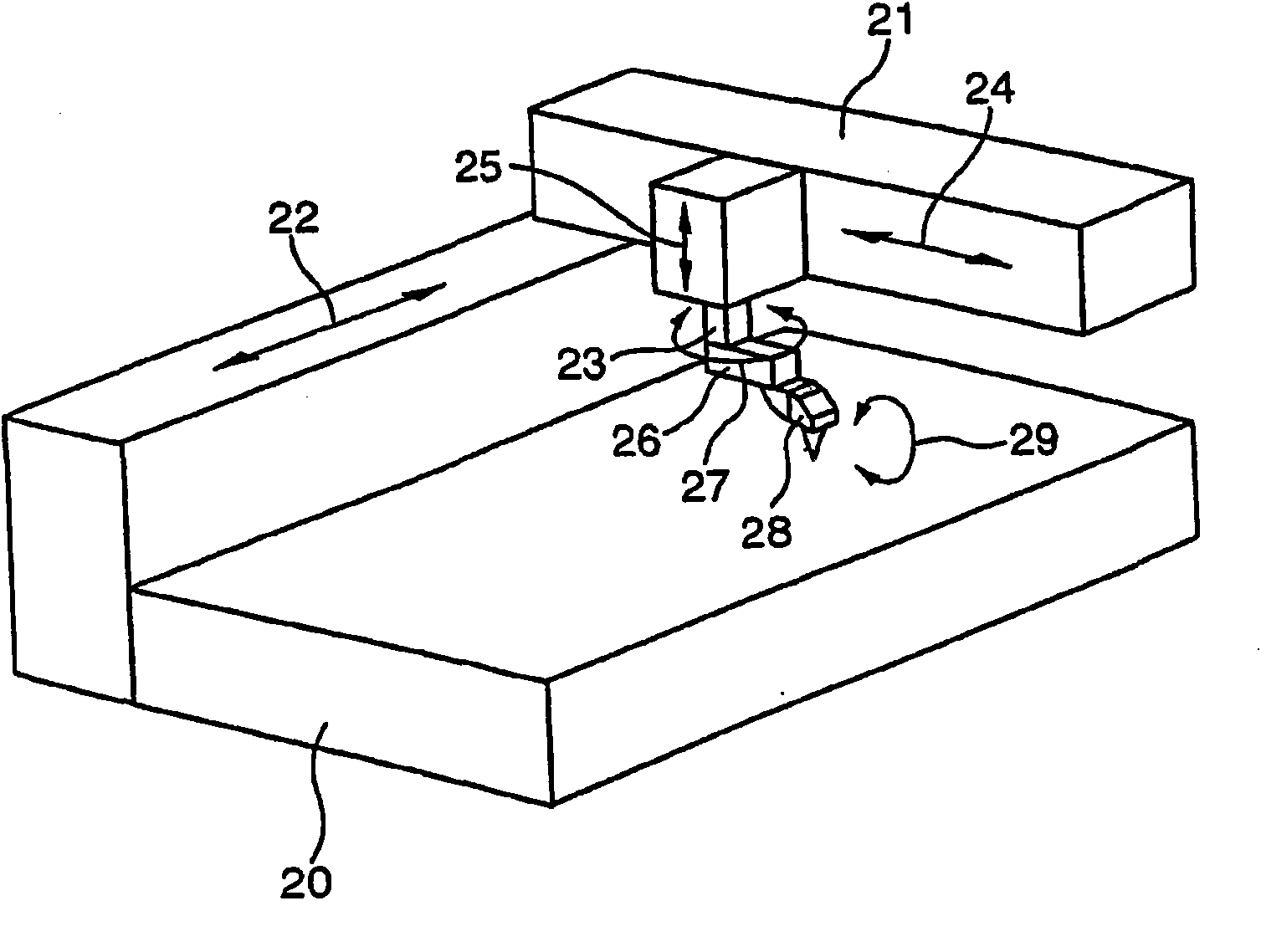

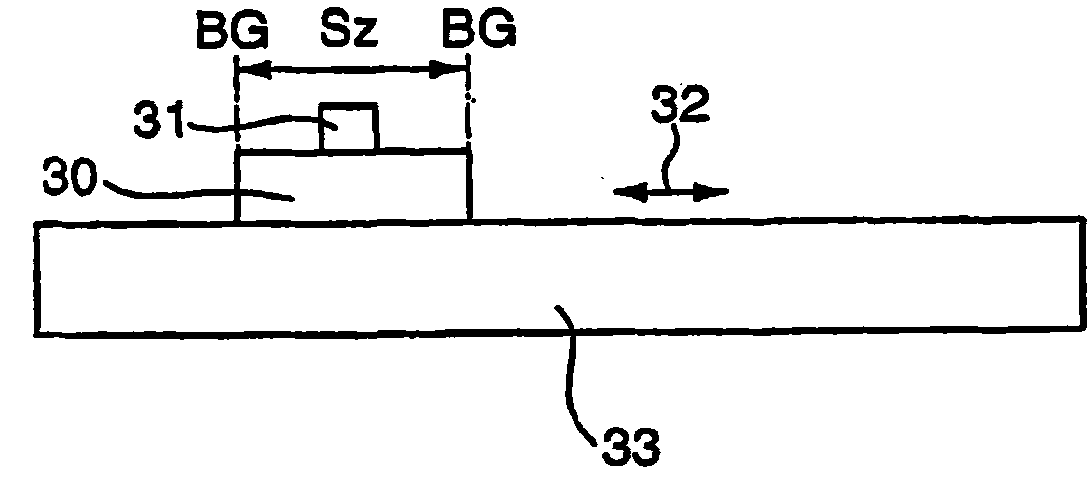

Method for the optimised movement co-ordination of measuring tools or machine-tools by means of redundant translatory axles

ActiveCN101784969ADoes not limit dynamicsPath component minimizationProgramme controlComputer controlEngineeringMachine tool

The invention relates to a method for the optimised movement co-ordination of measuring tools or machine-tools by means of redundant translatory axles, each longer partial axle enabling a relatively low-acceleration partial movement over a relatively large measuring or machining space, and each shorter partial axle carrying out, at an essentially generally constant measuring or machining speed, essentially the movement components of an entire movement, which require acceleration above the maximum determined for each longer partial axle. The invention is characterised in that, when positions are reached, which would otherwise not be reached in a non-divided movement, the base axles can brake correspondingly and even come to a complete standstill. The movement component of the base axles which is missing for the entire movement is compensated by the simultaneous displacement of the neutral starting point of the additional axles.

Owner:TRUMPF WERKZEUGMASCHINEN GMBH & CO KG

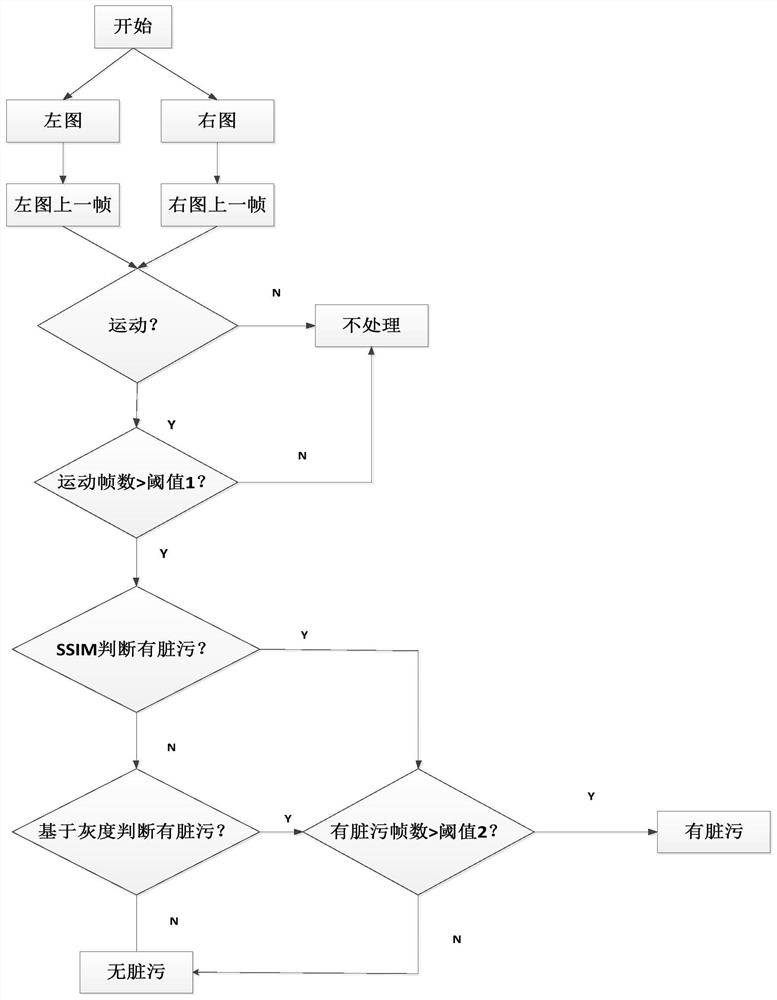

Method and device for detecting dirt of binocular ADAS camera

ActiveCN112215794AQuick checkQuick identificationImage enhancementImage analysisComputer graphics (images)Gradation

The invention discloses a method and device for detecting dirt of a binocular ADAS camera. The dirt can be efficiently detected. The method comprises the steps that A, whether a vehicle is in a movingstate or not is judged, if yes, the step B is executed, and if not, processing is not performed; B, judging whether the number of motion frames is greater than a threshold value 1 or not, if so, considering that the current vehicle is in motion, carrying out the step C, and if not, do not carrying out processing; C, whether the images of the two cameras are relatively consistent is judged, if yes, no dirt exists, and if not, the step D is executed, specifically, the step C comprises the steps that C1, the structural similarity is judged, if yes, the step D is executed, and otherwise, the stepC2 is executed; C2, gray scale comparison is carried out, if it is judged that dirt exists through gray scale comparison, the step D is carried out, and otherwise it is judged that no dirt exists; and D, judging whether the frame number of the dirty image is greater than a threshold value 2, if so, judging that dirt exists, and if not, judging that no dirt exists.

Owner:BEIJING SMARTER EYE TECH CO LTD

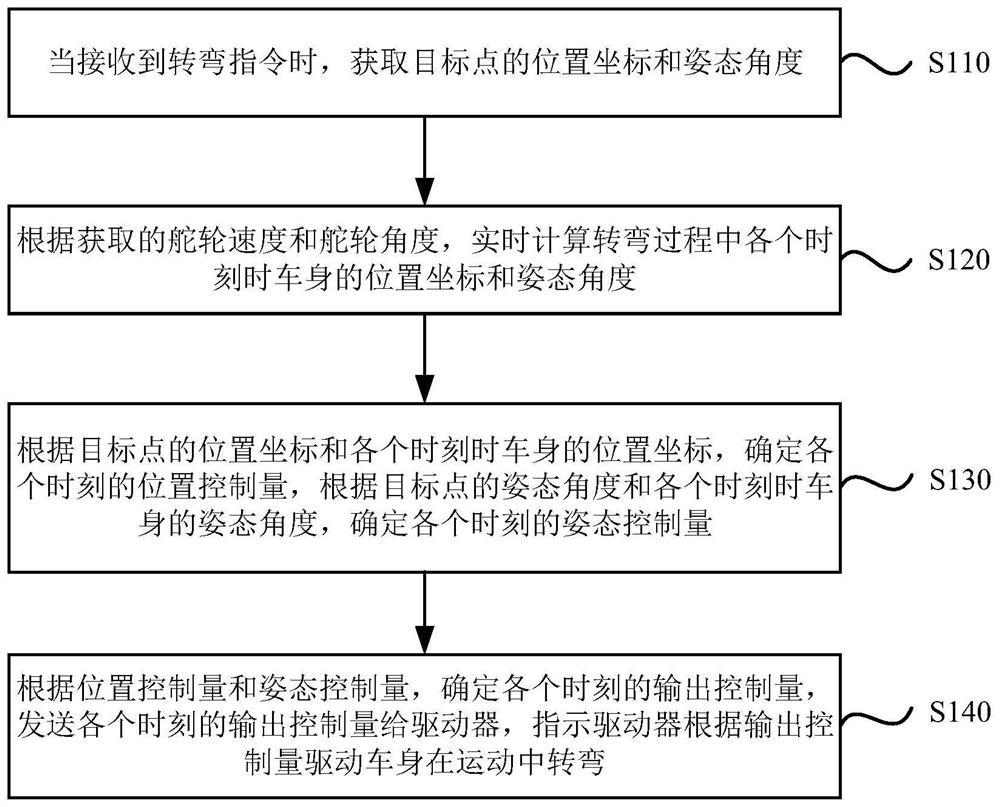

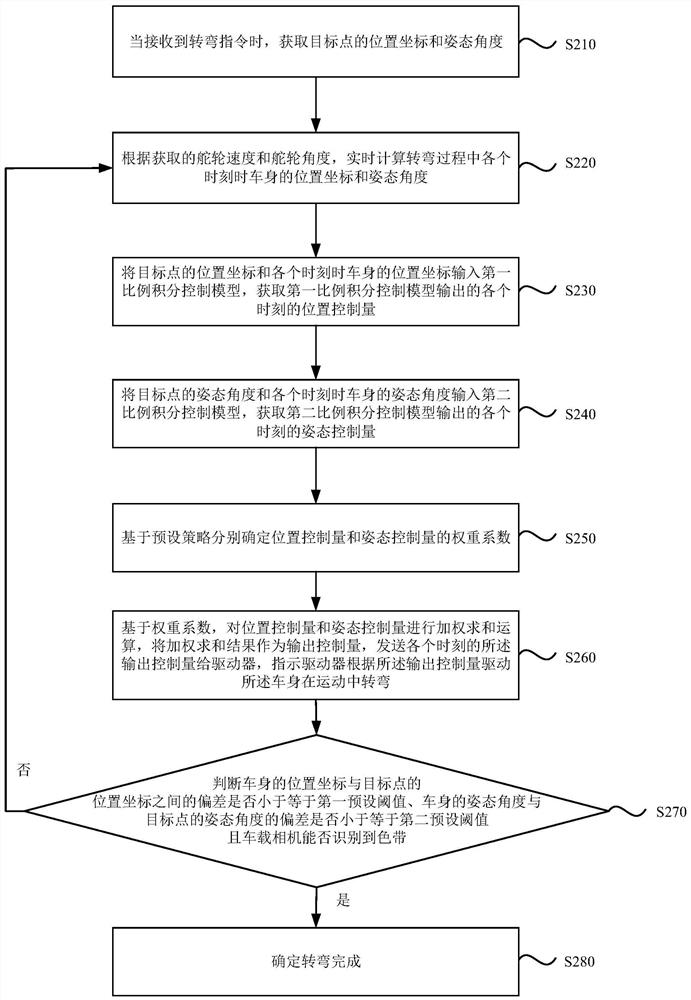

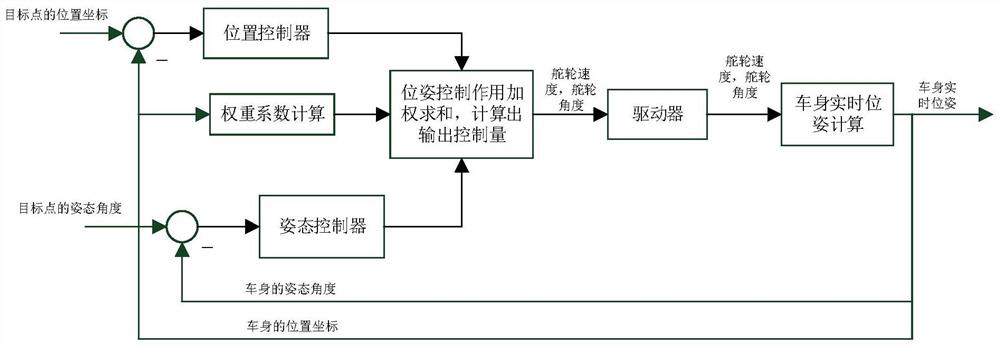

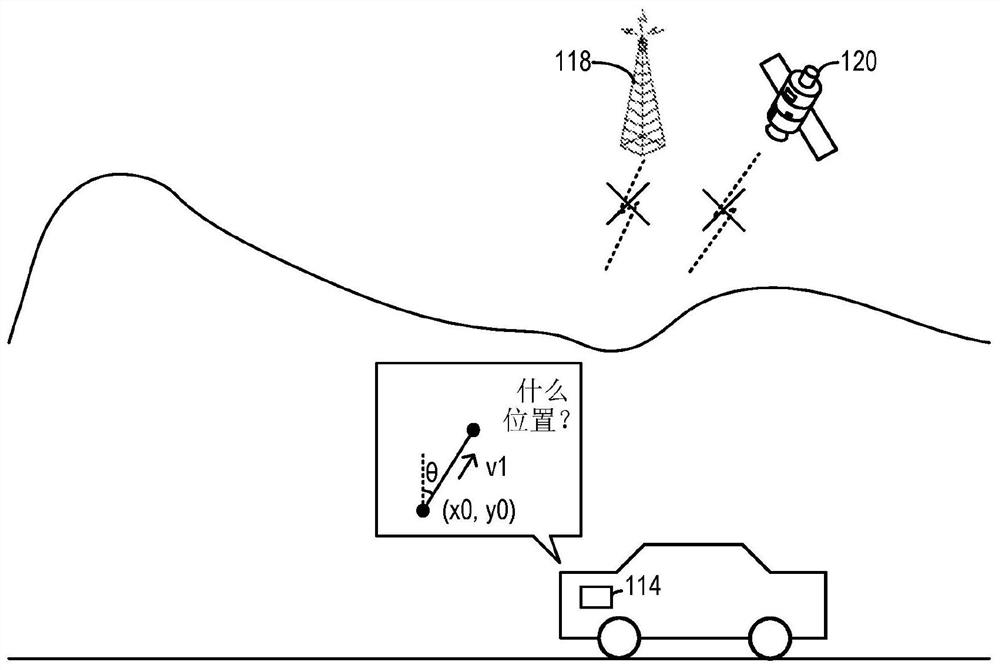

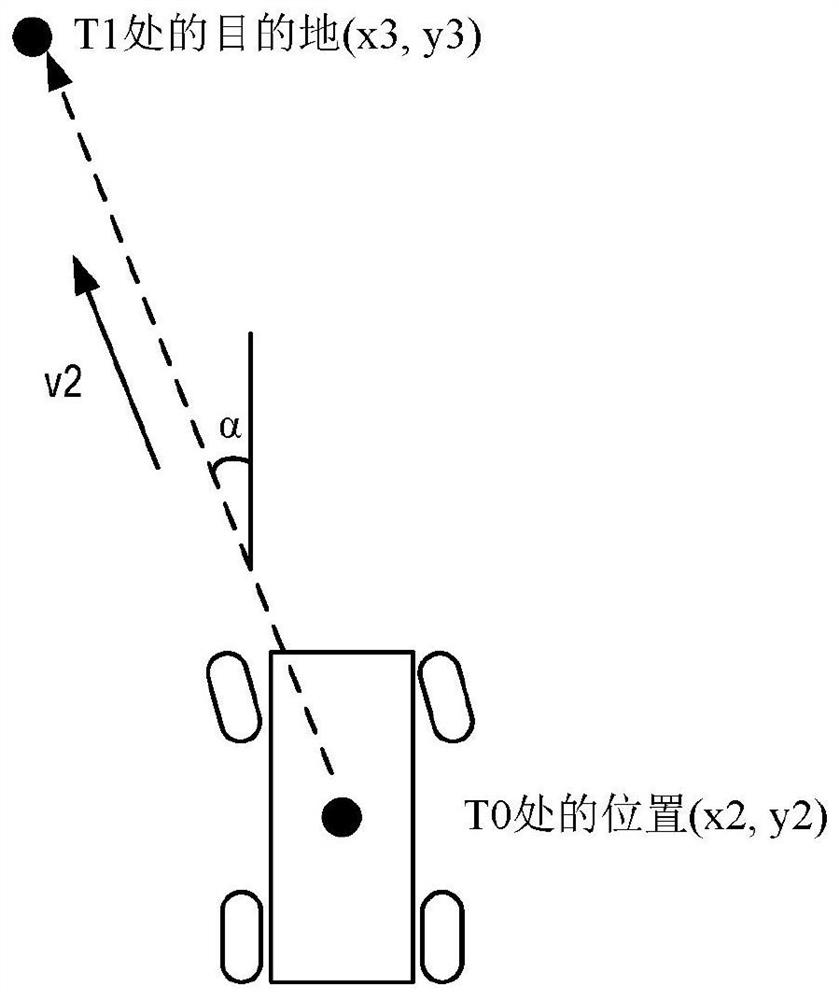

Turning control method, device and system of unmanned mobile device and storage medium

ActiveCN111966101AAvoid parkingSimplify the turning processPosition/course control in two dimensionsVehiclesSteering wheelAttitude control

The embodiment of the invention discloses a turning control method, device and system of an unmanned mobile device and a storage medium. The method comprises the steps that when a turning instructionis received, acquiring the position coordinate and the posture angle of a target point; according to the obtained steering wheel speed and steering wheel angle, calculating position coordinates and attitude angles of the vehicle body at each moment in the turning process in real time; determining the position control quantity of each moment according to the position coordinates of the target pointand the position coordinates of the vehicle body at each moment, and determining the attitude control quantity of each moment according to the attitude angle of the target point and the attitude angle of the vehicle body at each moment; and according to the position control quantity and the attitude control quantity, determining the output control quantity of each moment, sending the output control quantity of each moment to a driver, and indicating the driver to drive the vehicle body to turn in motion according to the output control quantity. By calculating the position coordinates and theattitude angle of the vehicle body in real time, the position coordinates and the attitude angle are respectively controlled, the turning time is shortened, and the turning efficiency is improved.

Owner:国以贤智能科技(上海)股份有限公司

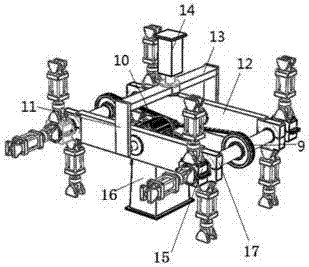

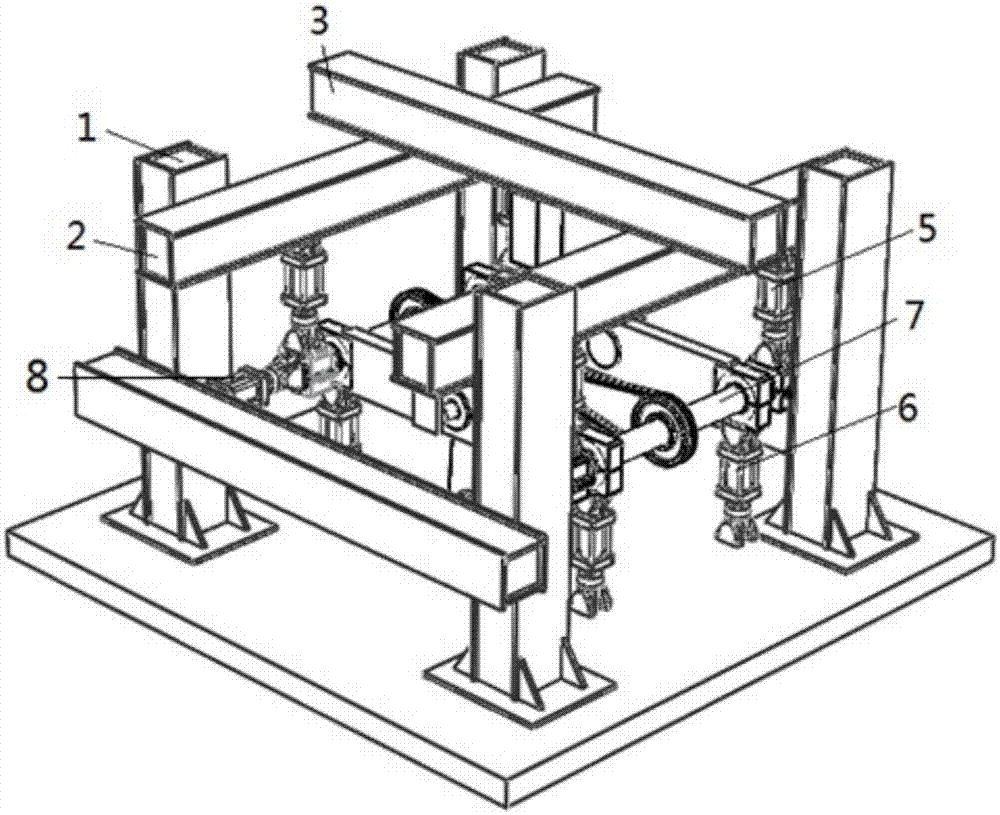

High-frequency vibration test bed for axle-end bearing of double-axle and double-rotation railway vehicle

PendingCN107314901AImprove the state of stressImprove reliabilityMachine bearings testingEngineeringTest platform

The invention provides a high-frequency vibration test bed for the axle-end bearing of a double-axle and double-rotation railway vehicle. The test bed comprises a framework, a motor, a simulation static load actuator, a vertical actuator, a transverse actuator, simulation wheel shafts and an axle-end axle box. The test bed is characterized in that one simulation wheel shaft is connected with the front end and the rear end of the motor respectively. Each simulation wheel shaft is provided with a wheel-set simulation axle box positioned corresponding to a wheel set and a bearing is arranged inside the wheel-set simulation axle box. The vertical actuator is arranged right below wheel-set simulation axle boxes. Two wheel-set simulation axle boxes, arranged front and back, are connected with each other through longitudinal supporting beams. Two longitudinal supporting beams are movably connected through a transverse supporting beam. The upper part of the transverse supporting beam is movably connected with a framework upper cross beam through a horizontal rotating shaft. According to the invention, the high-speed rotation and high-frequency vibration conditions of a bearing during the movement of the railway vehicle can be truly simulated in a laboratory. More accurate and detailed experimental data can be obtained through transversely and vertically applying a shock excitation. Therefore, the test bed provides more reliable test data for the design production and the maintenance of axle-box bearings.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

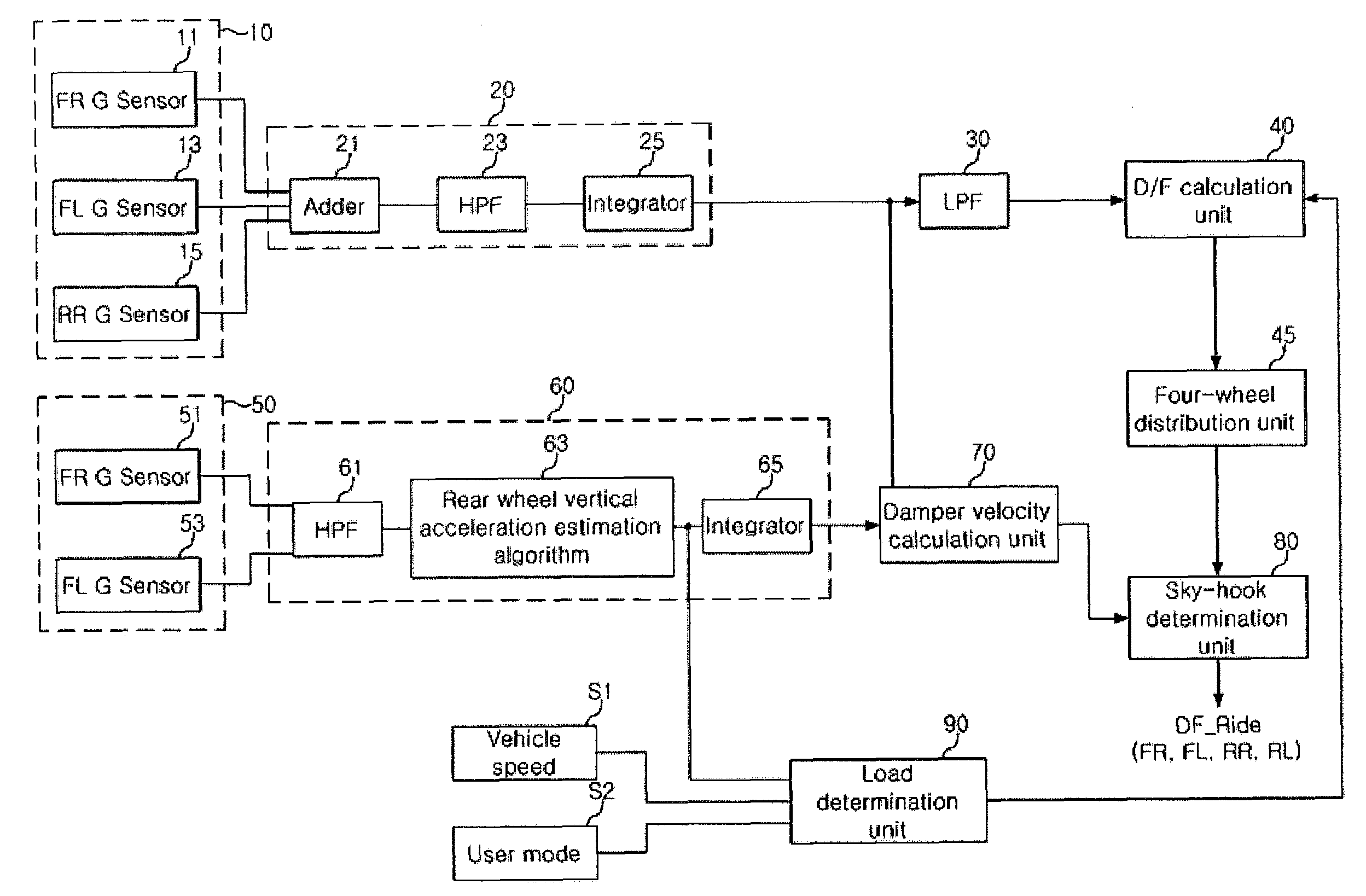

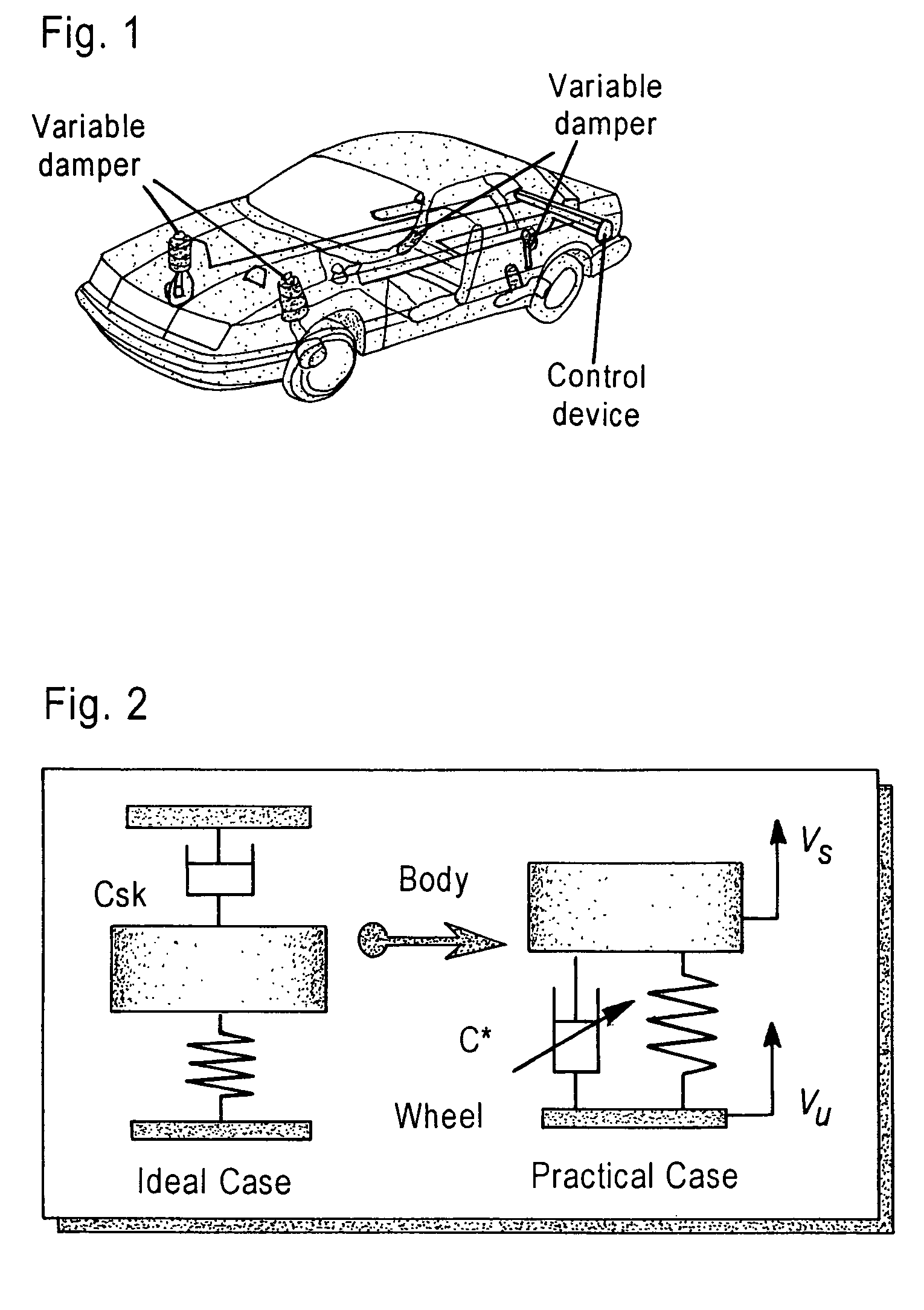

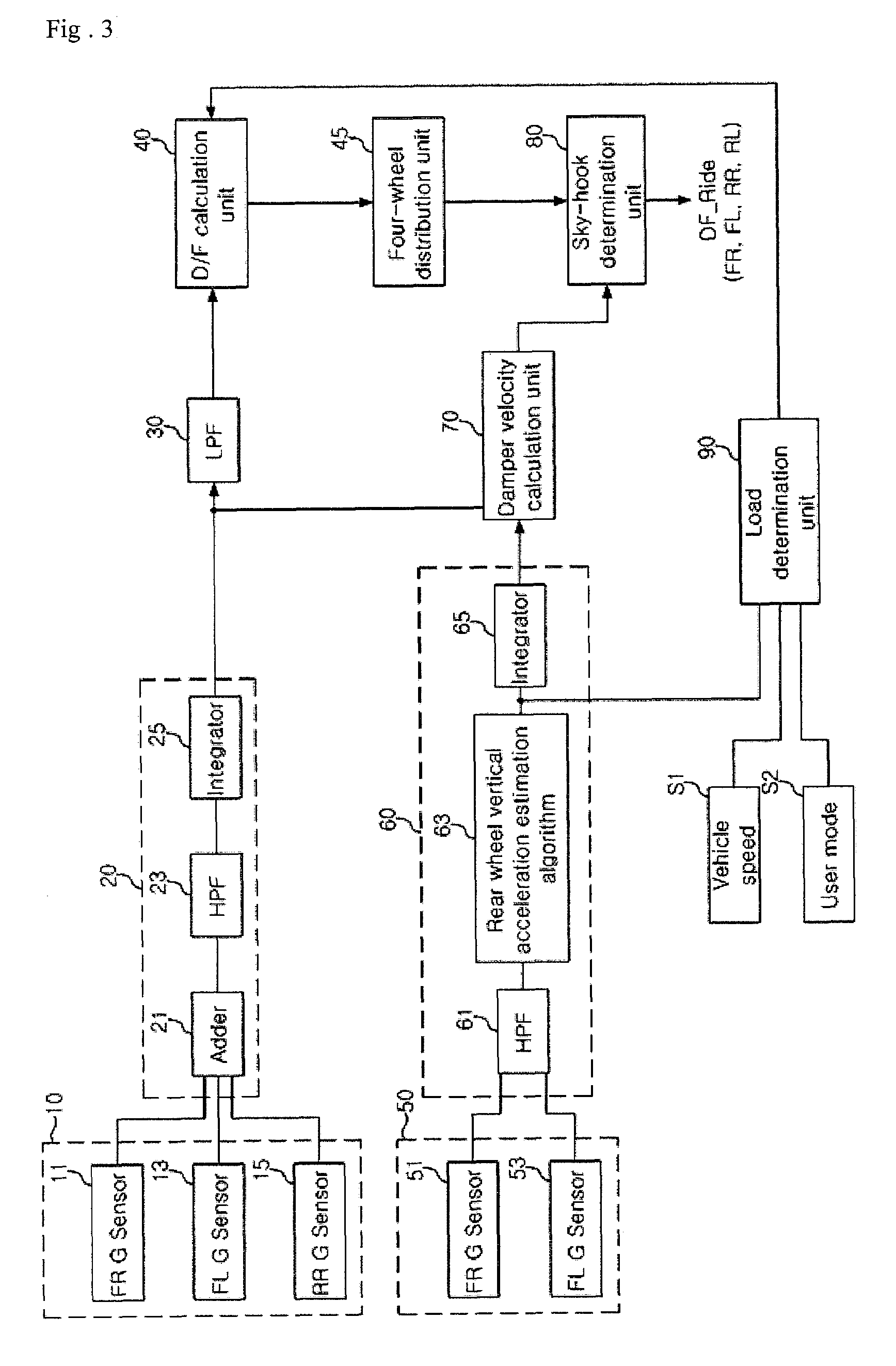

Method for controlling variable damper in vehicle

The present invention relates to a method of controlling a variable damper in a vehicle wherein a rear-wheel variable damper can be controlled by estimating a vertical acceleration value of a rear wheel based on the fact that there is a certain time delay in a wheel motion between front and rear wheels due to the wheelbase and vehicle speed. To this end, the method of the present invention comprises the steps of (a) detecting vehicle body accelerations other than a desired vehicle body acceleration of a vehicle body; (b) calculating the desired vehicle body acceleration based on the other detected vehicle body accelerations according to a geometric rule; (c) calculating vehicle body vertical velocities by filtering the vehicle body accelerations to eliminate DC offsets therefrom and integrating the filtered accelerations; (d) detecting accelerations of front right / left vehicle wheels; (e) calculating front wheel vertical velocities by filtering the detected accelerations of the front right / left wheels to eliminate DC offsets therefrom and integrating the filtered accelerations, and then calculating accelerations of rear wheels by time delaying the accelerations of the front wheels by a time interval taken while a road input to the front wheel is delivered to the rear wheel at a vehicle speed; and (f) calculating damper velocities based on the calculated vehicle body vertical velocities and the calculated vehicle wheel vertical velocities. Accordingly, the Sky-hook determination can be more accurately made. Further, since it is not necessary to use all the four sensors, the number of parts of vehicles can be reduced when mass-producing the vehicles. Consequently, the selling prices for finished vehicles can be lowered, and thus, an unnecessary economical burden cannot be imposed on the consumers.

Owner:HL MANDO CORP

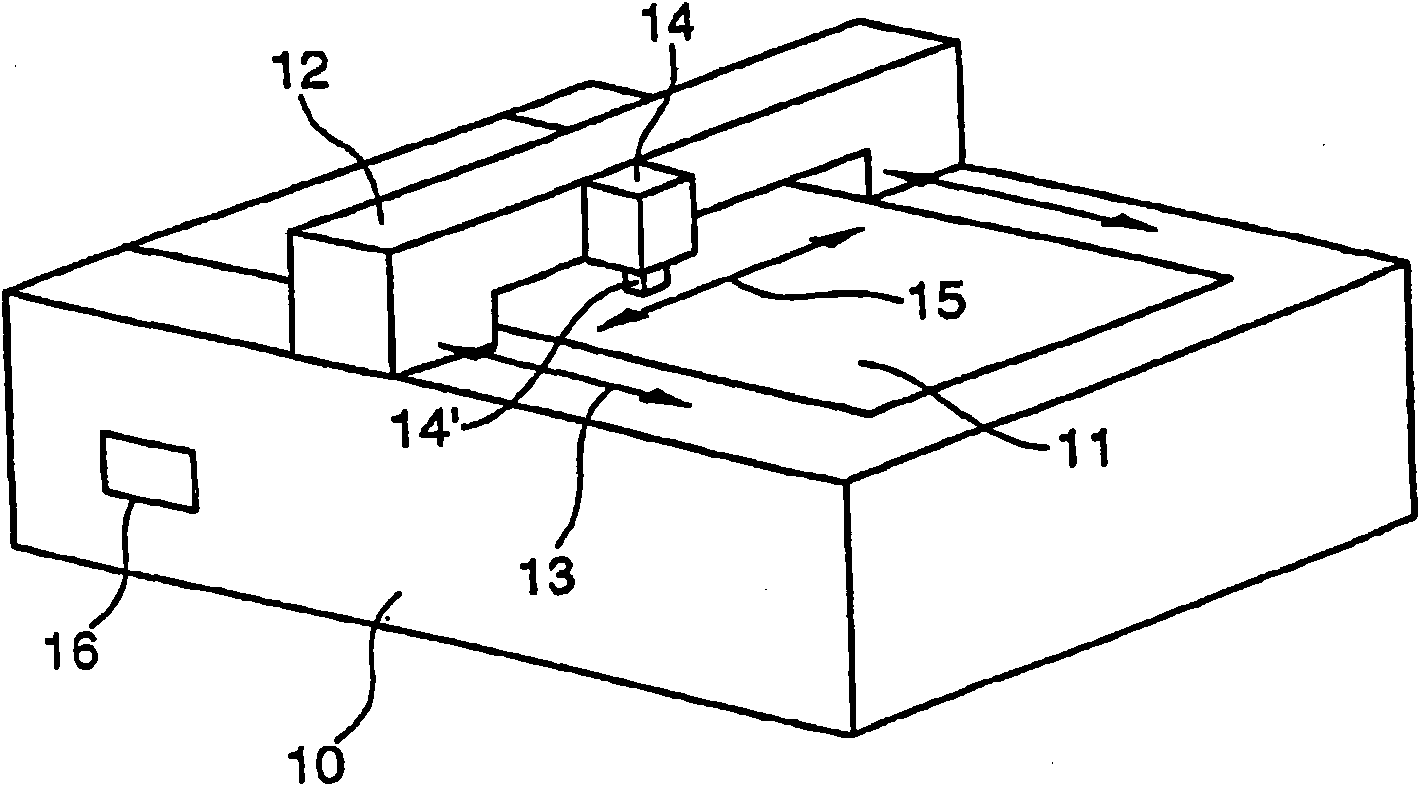

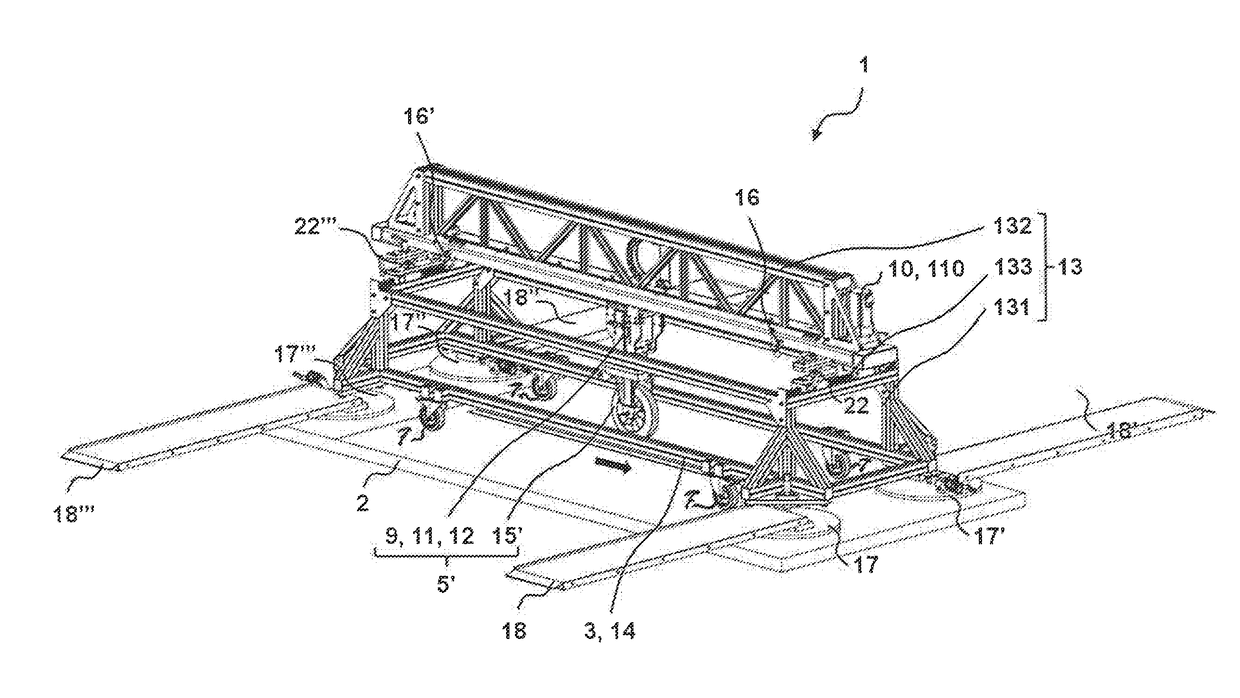

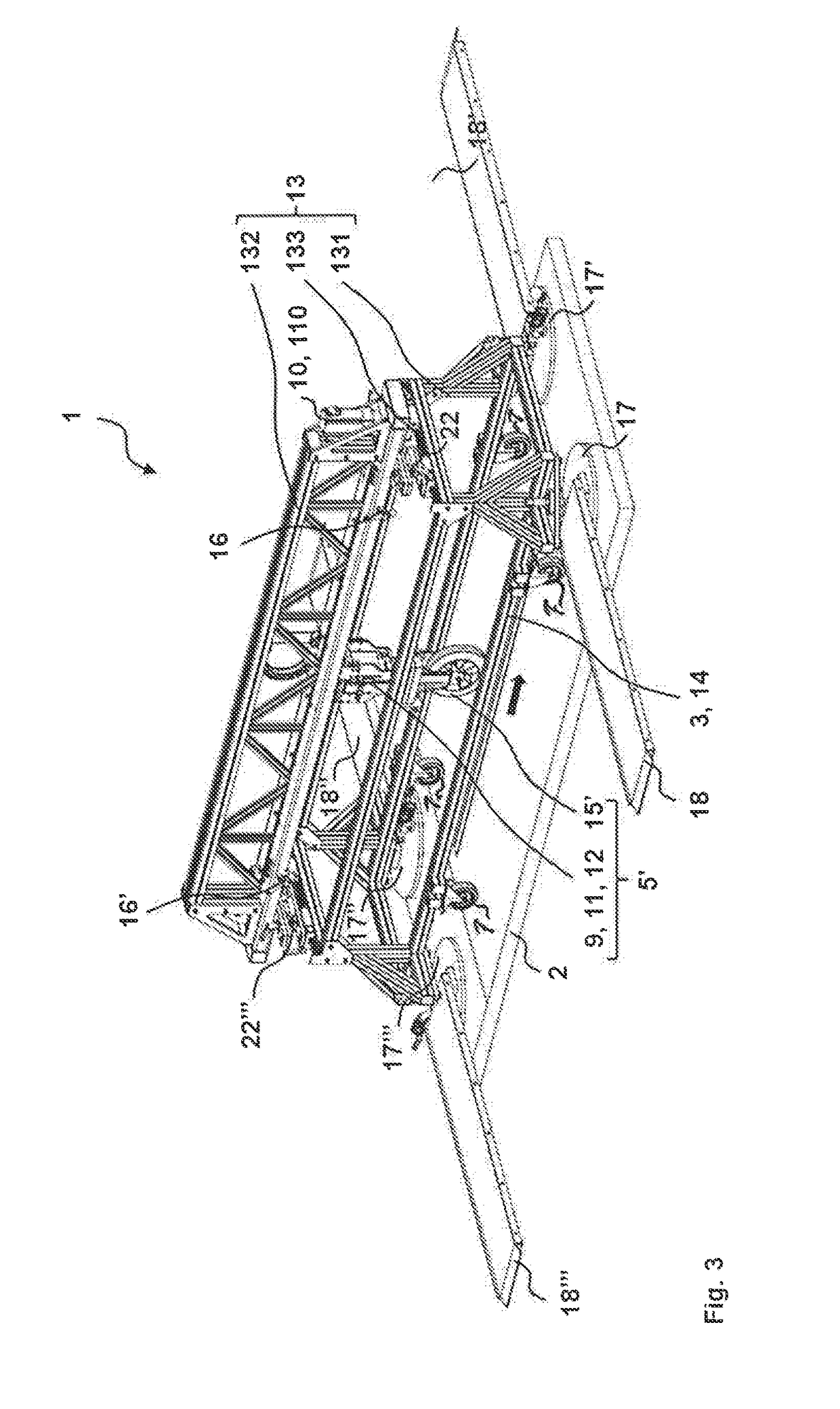

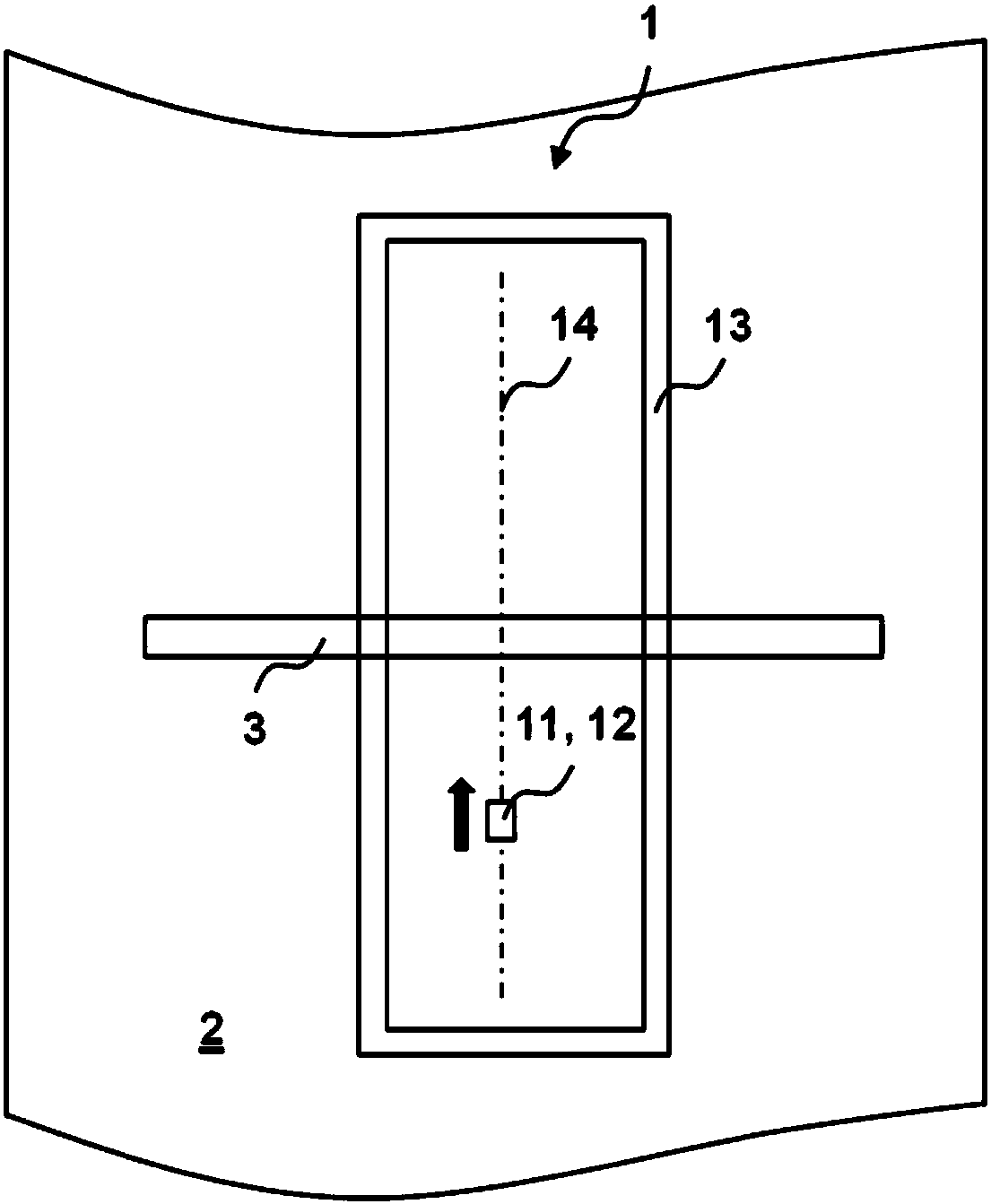

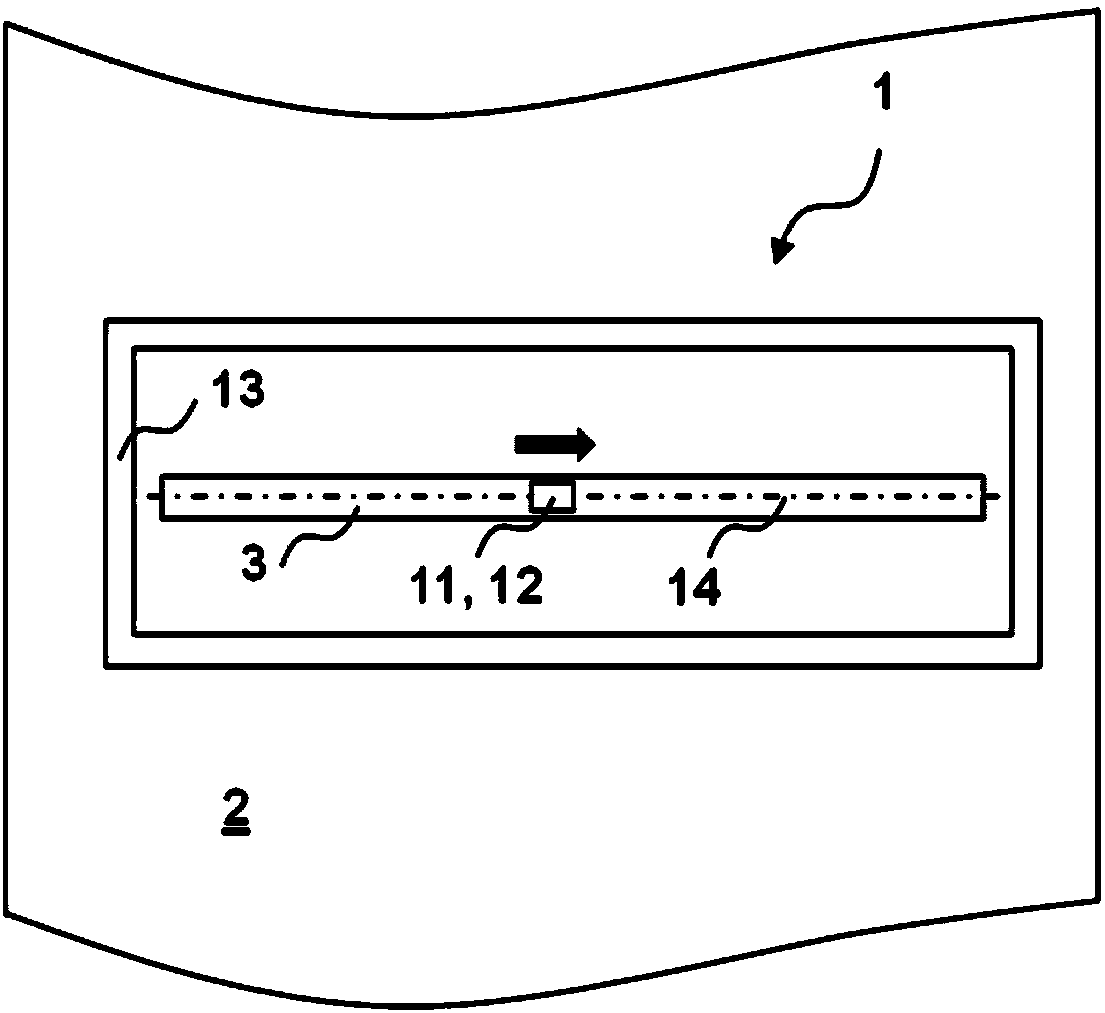

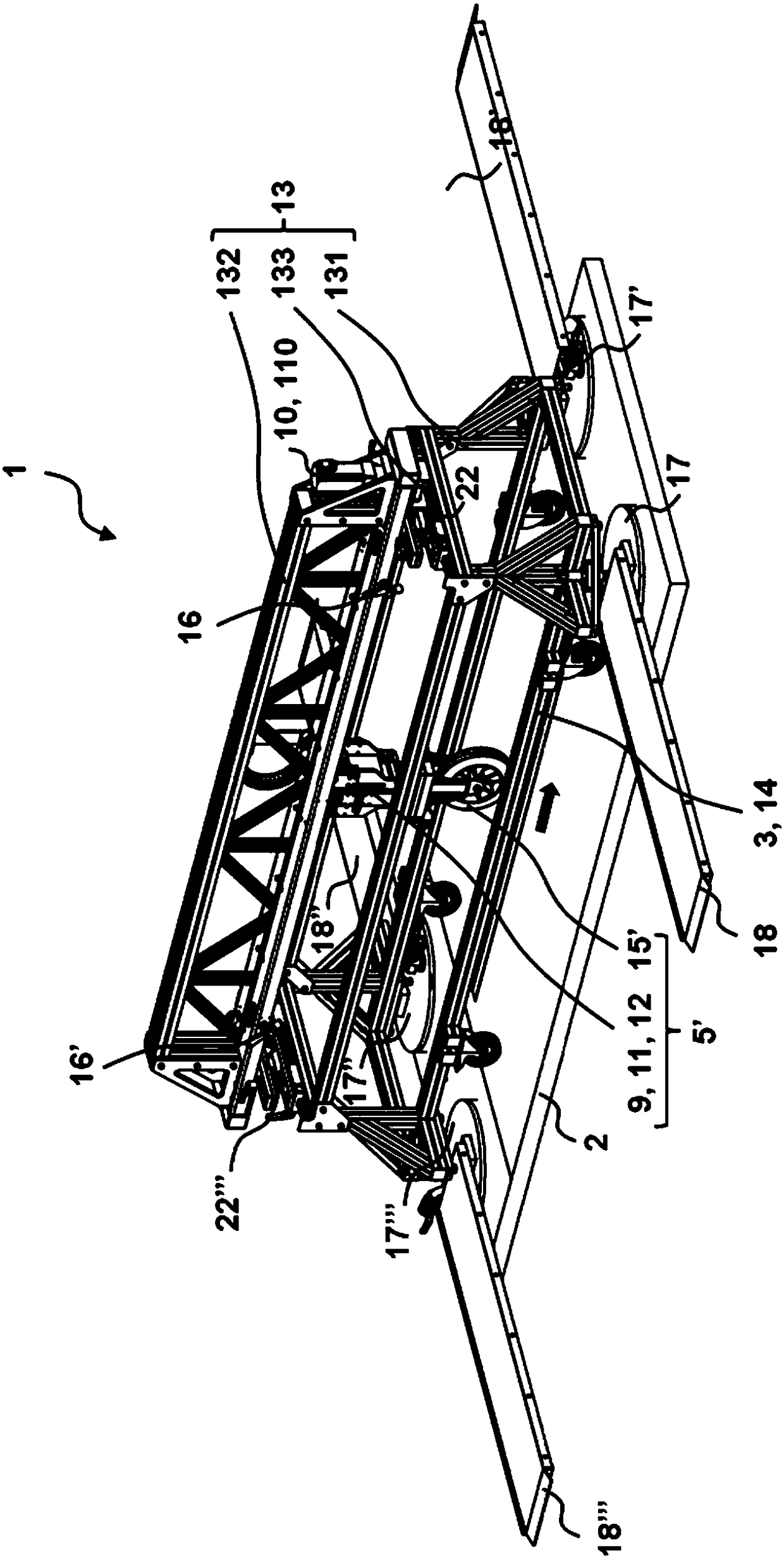

Apparatus and method for calibrating a weigh-in-motion sensor

ActiveUS20180245970A1Low accuracyImprove accuracyWeighing apparatus using elastically-deformable membersWeighing apparatus testing/calibrationEngineeringActuator

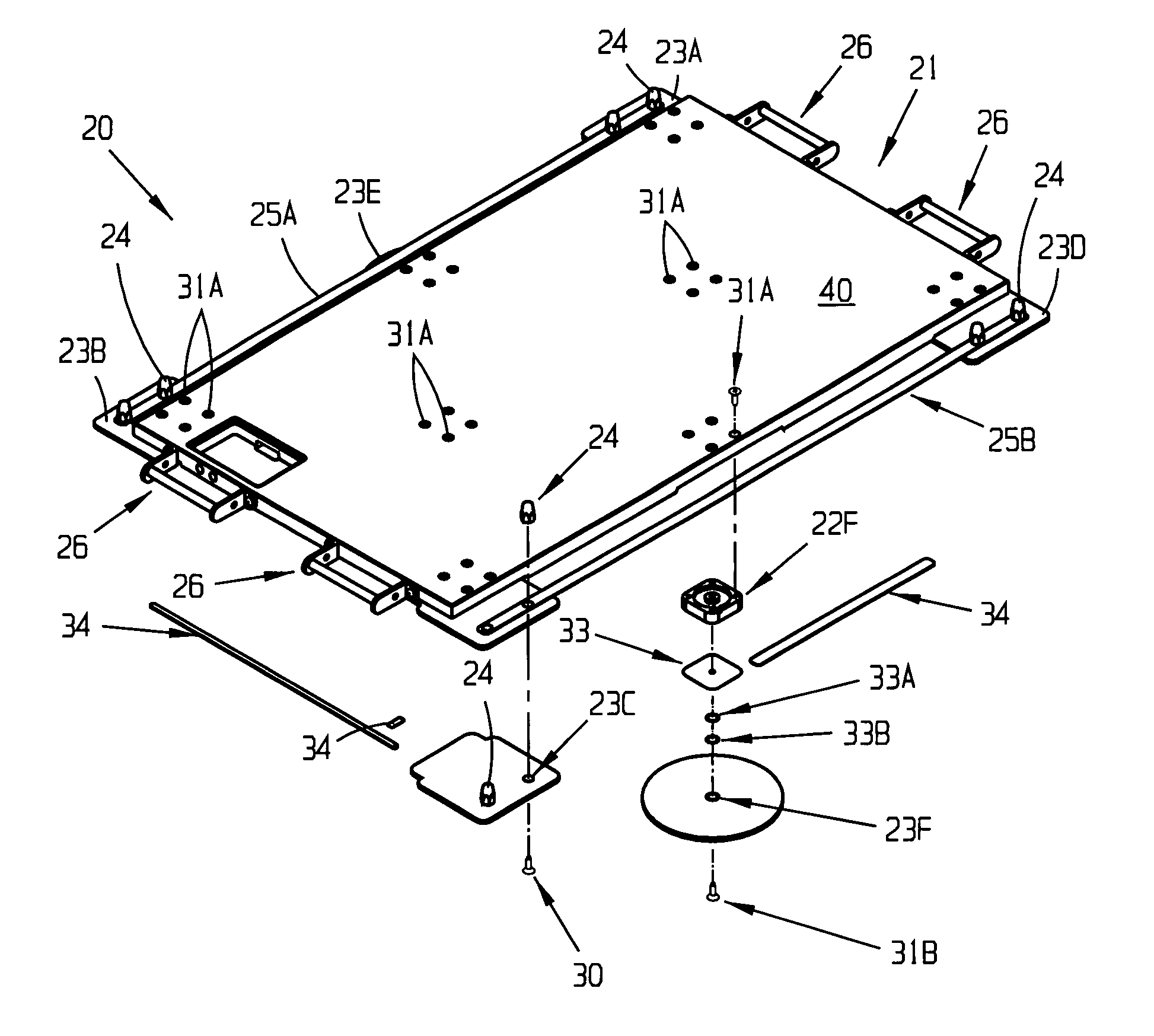

An apparatus for calibrating a weigh-in-motion (WIM) sensor embedded in a roadway includes an actuator, an applicator, a force sensor disposed between the actuator and the applicator, and a carriage supporting the actuator, the applicator and the force sensor, which carriage is selectively movable on a longitudinal support carried by a frame. The apparatus also includes a drive unit to move the applicator along the longitudinal support as well as a position sensor that detects a position of the calibration path relative to the WIM sensor. According to a method for calibrating a WIM sensor, the frame is positioned to straddle the WIM sensor. The applicator introduces along the calibration path at a succession of different positions, a reference force that is measured by the WIM sensor and the force sensor, and these measurements are compared to generate a calibration.

Owner:KISTLER HLDG AG

Method for calibrating WIM-sensors

ActiveUS9851241B2Weighing apparatus testing/calibrationSpecial data processing applicationsData synchronizationEngineering

A method for calibrating a WIM (Weigh in Motion) sensor built into a road during travel of a calibrating vehicle measures the dynamic wheel force on the road and on the WIM sensor directly at the measuring wheel, depending on time or location. These wheel force data are transmitted to an evaluating unit. As the calibrating vehicle passes over, WIM signal data are simultaneously measured at the WIM sensor and transmitted to the evaluating unit. The wheel force data are synchronized with the WIM signal data in the evaluating unit. A calibration function is determined by comparing the dynamic wheel force data with the WIM signal data.

Owner:KISTLER HLDG AG

Vehicle operation based on vehicular measurement data processing

PendingCN111868479AInstruments for road network navigationNavigation by speed/acceleration measurementsSimulationWeigh in motion

Methods, apparatuses, and computer-readable media are described. In one example, a method of controlling a vehicle comprises: receiving, using one or more sensors, a first set of measurements of a setof physical attributes of the vehicle in a motion; determining, based on a motion data model that defines a set of relationships among the set of physical attributes of the vehicle in the motion andbased on the first set of measurements, a set of expected measurements of the set of physical attributes; determining whether to use an entirety of the first set of measurements to control an operation of the vehicle based on comparing the first set of measurements and the set of expected measurements; and responsive to determining not to use the entirety of the first set of measurements, controlling the operation of the vehicle based on a second set of measurements.

Owner:QUALCOMM INC

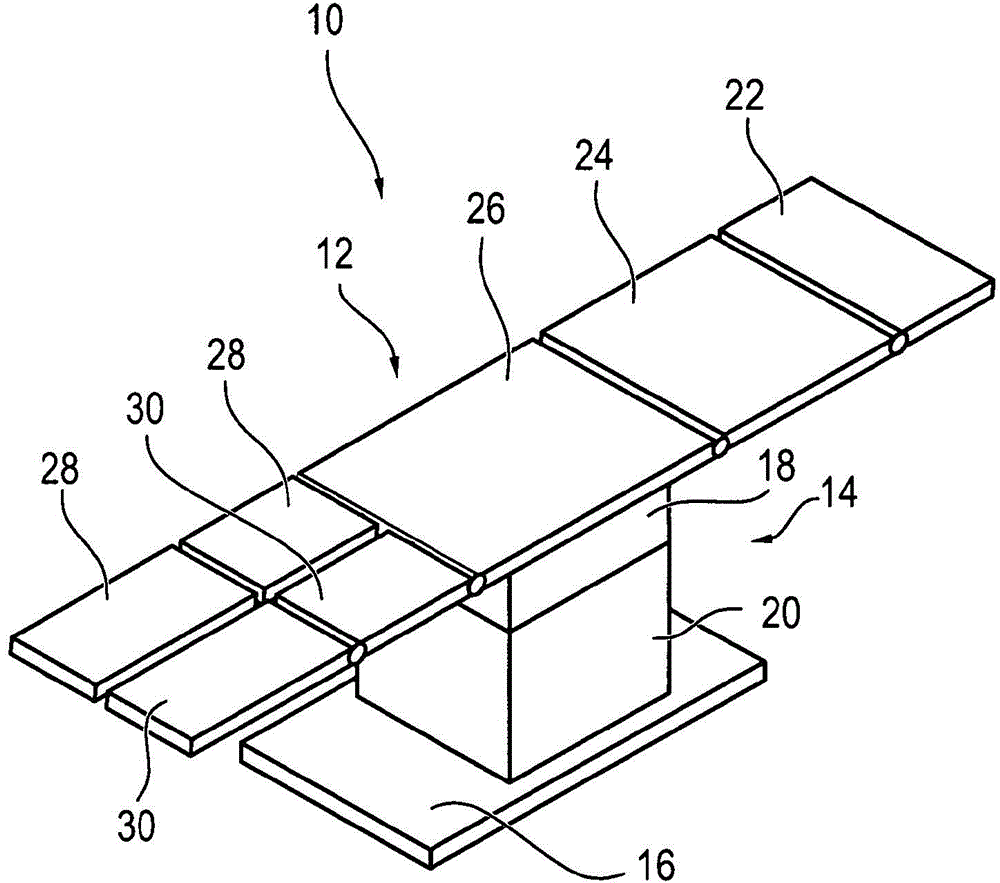

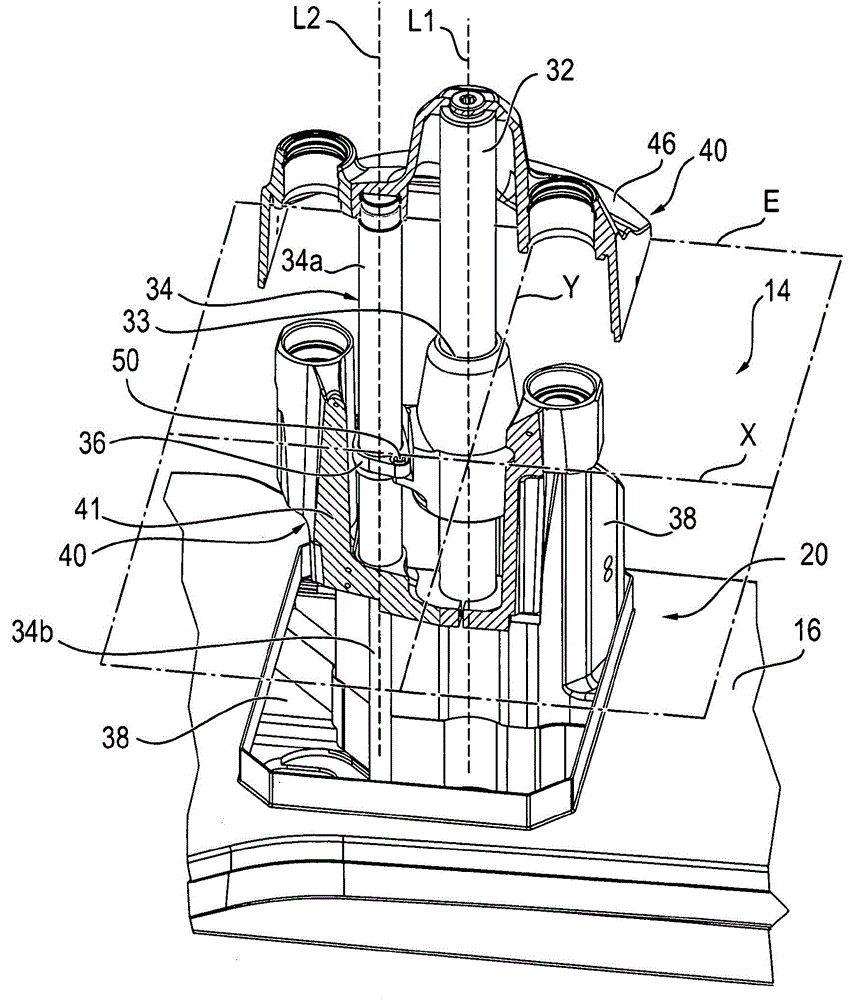

Device for adjusting the height of an operation table

ActiveCN105310852AAvoid supportImprove rigidityOperating tablesNursing bedsEngineeringOperating table

A device for height adjustment of an operating table (10), including a lifting carriage (40) which is movable relative to a chassis (38) of the operating table (10), including a primary guide (32, 33) having a first longitudinal axis (L1) about which the lifting carriage (40) is rotatable, including a secondary guide (34a) having a second longitudinal axis (L2), and including a guide means (36) which is connected to the chassis (38) of the operating table (10) and which has a contact area in which the guide means (36) contacts the secondary guide (34a) in a contact area of the secondary guide (34a). The primary guide (32, 33) and the secondary guide (34a) serve for guiding a lifting motion of the lifting carriage (40) within an adjustment range of the lifting carriage (40) parallel to the first longitudinal axis (L1), wherein a plane (E) extending perpendicular to the first longitudinal axis (L1) and through the guide means (36) has a first point of intersection (S1) with the first longitudinal axis (L1) and a second point of intersection (S2) with the second longitudinal axis (L2), and wherein the position (P1, P2) of the second point of intersection (S2) changes by a displacement distance (53) during the lifting motion of the lifting carriage (40) within the adjustment range thereof. The connection between the guide means (36) and the chassis (38) permits a complementing motion of the guide means (36) such that the contact area of the guide means (36) is shiftable by said displacement distance (53).

Owner:MAQUET GMBH

Apparatus and method for calibrating a weigh-in-motion sensor

ActiveCN108507659AWeighing apparatus using elastically-deformable membersWeighing apparatus testing/calibrationCarriagewayEngineering

The invention relates to a device (1) for calibrating a Weigh-In-Motion (WIM) sensor (3) installed in a roadway (2); which device (1) has at least one force sensor (12), which force sensor (12) detects a reference force with which reference force of the WIM sensor (3) can be calibrated; which device (1) has an applicator (15-15 "), with which applicator (15-15") the reference force can be introduced into the carriageway (2); wherein the device (1) comprises an actuator (11), which actuator (11) generates the reference force; and wherein the actuator (11), force sensor (12) and applicator (15-15 ") are mechanically interconnected and form a vehicle (5-5").

Owner:KISTLER HLDG AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com