Automatic lifting mechanism and filling machine

A technology of automatic lifting and installation of plates, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of large space occupation, high labor intensity, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

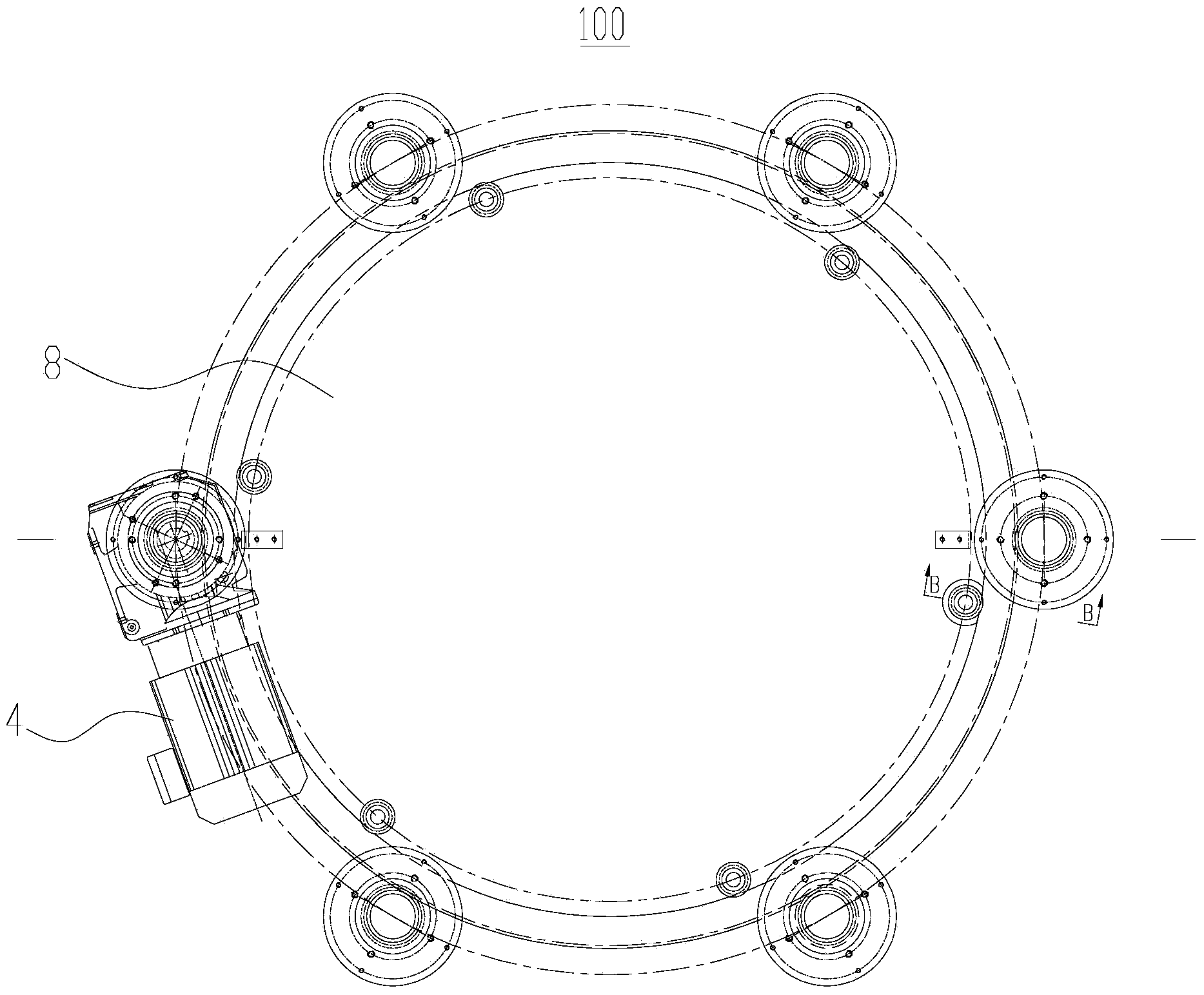

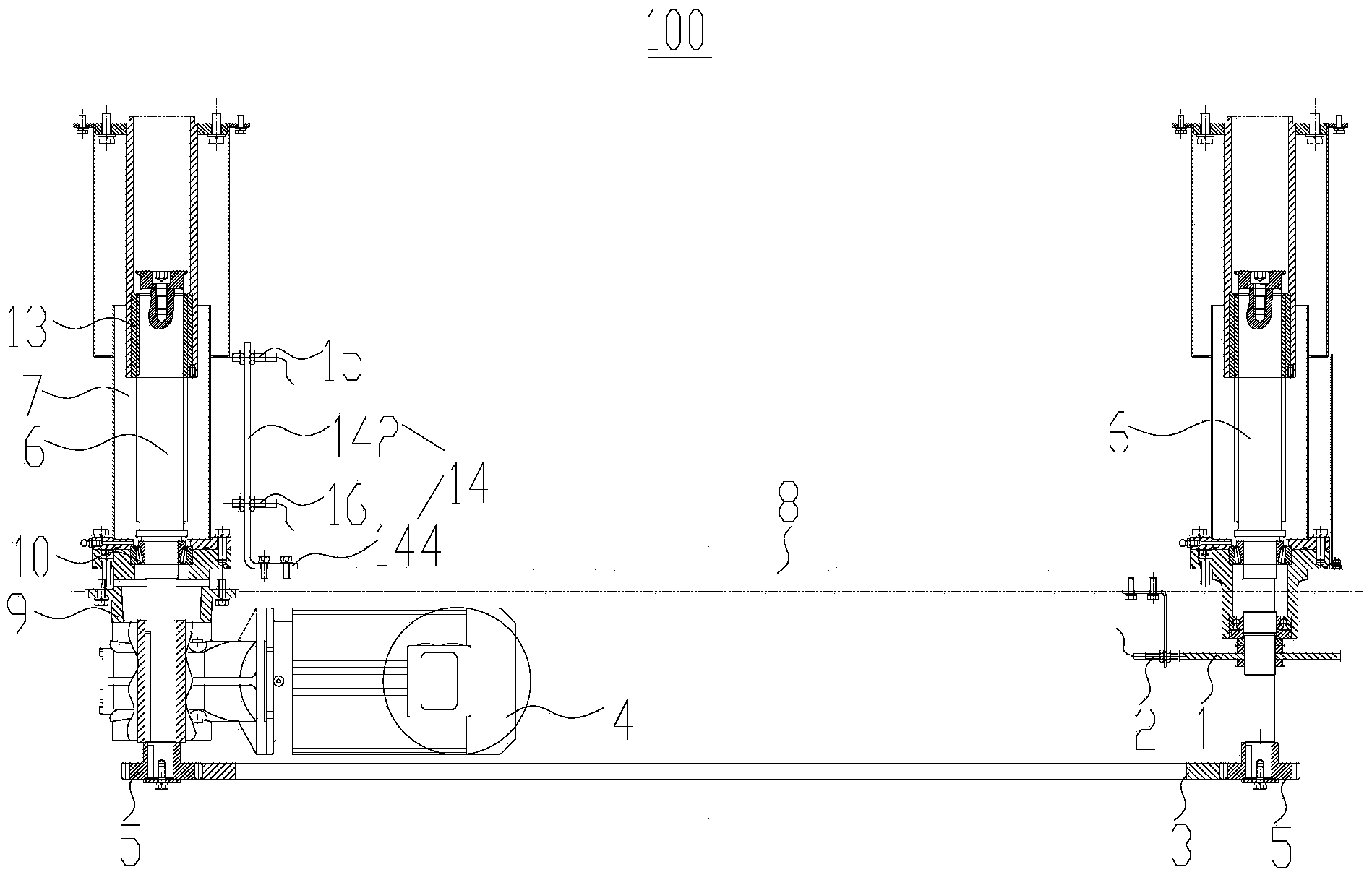

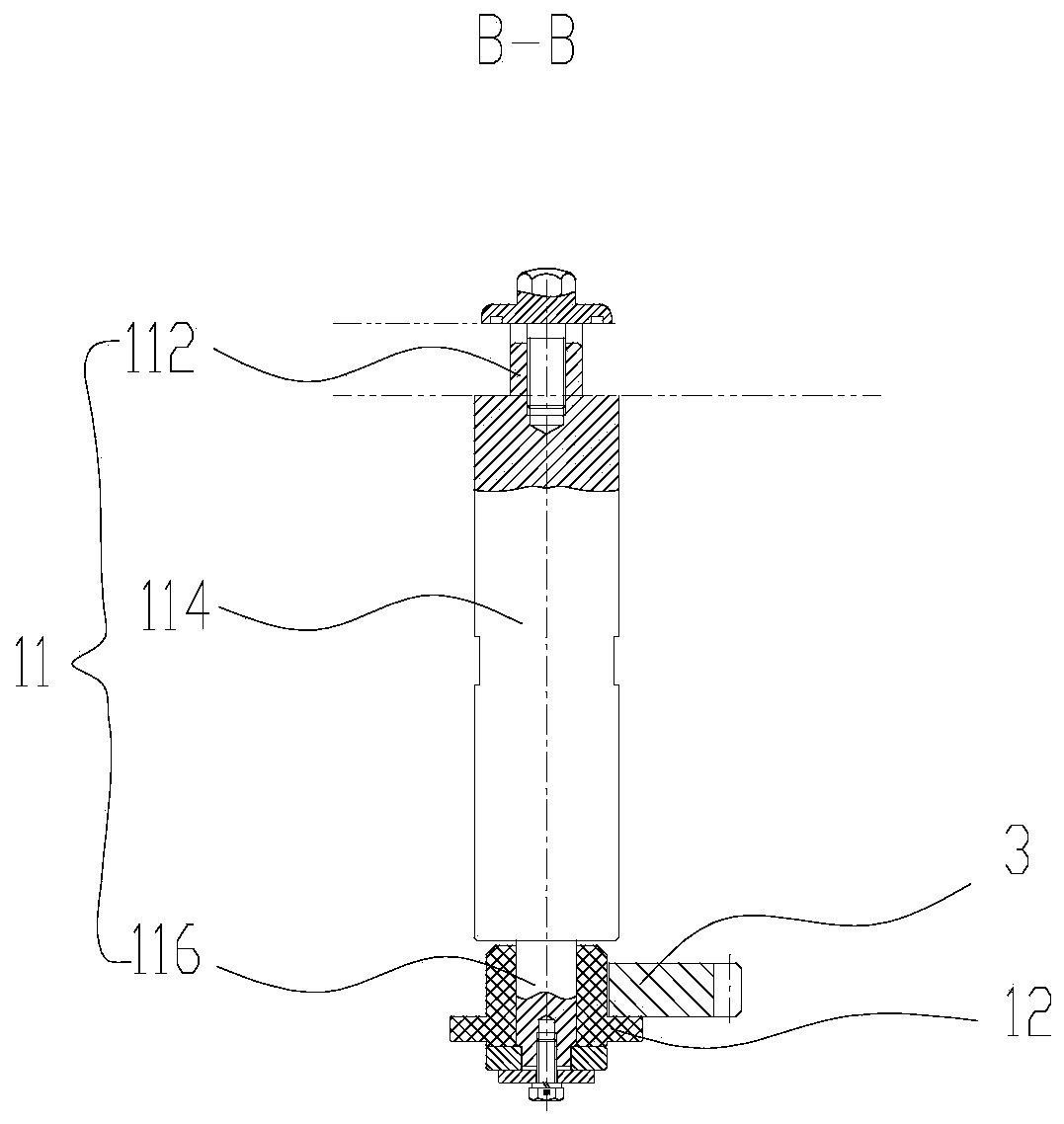

[0023] Such as Figure 1 to Figure 5 As shown, an automatic lifting mechanism 100 includes a detection board 1, a detection switch 2 matched with the detection board 1, a central gear 3, a motor 4, and at least two pinions 5, and the pinion 5 is along the circumference of the central gear 3 The direction is evenly arranged, and the pinion 5 is meshed with the central gear 3, and the pinion 5 is provided with studs 6, and each of the studs 6 is provided with a matching nut 7, and one of the studs 6 is connected with the motor 4, and the detection board 1 is installed on one of the studs 6.

[0024] The automatic lifting mechanism 100 described in this example has a simple structure and is easy to install. By arranging a plurality of small gears 5 evenly in the circumferential direction of the central gear 3, the operation of the motor 4 drives the connected stud 6 to rotate. The connected pinion 5 rotates synchronously, thereby driving the central gear 3 to rotate, further dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com