Leak checking device and leak checking method for blast furnace multi-stage connection closed circulation cooling water system

A technology of cooling water system and closed circulation, which is applied in the direction of cooling devices, inspection devices, etc., can solve the problem of difficulty in meeting the requirements of the blast furnace multi-stage connection closed circulation cooling water system, long head and low water pressure, and inability to quickly and accurately find leaks Points and other problems to achieve the effect of saving time and manpower for leak detection, reducing fuel consumption, and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention shall not be limited in any way, and any changes or improvements made based on the teaching of the present invention shall fall within the scope of protection of the present invention.

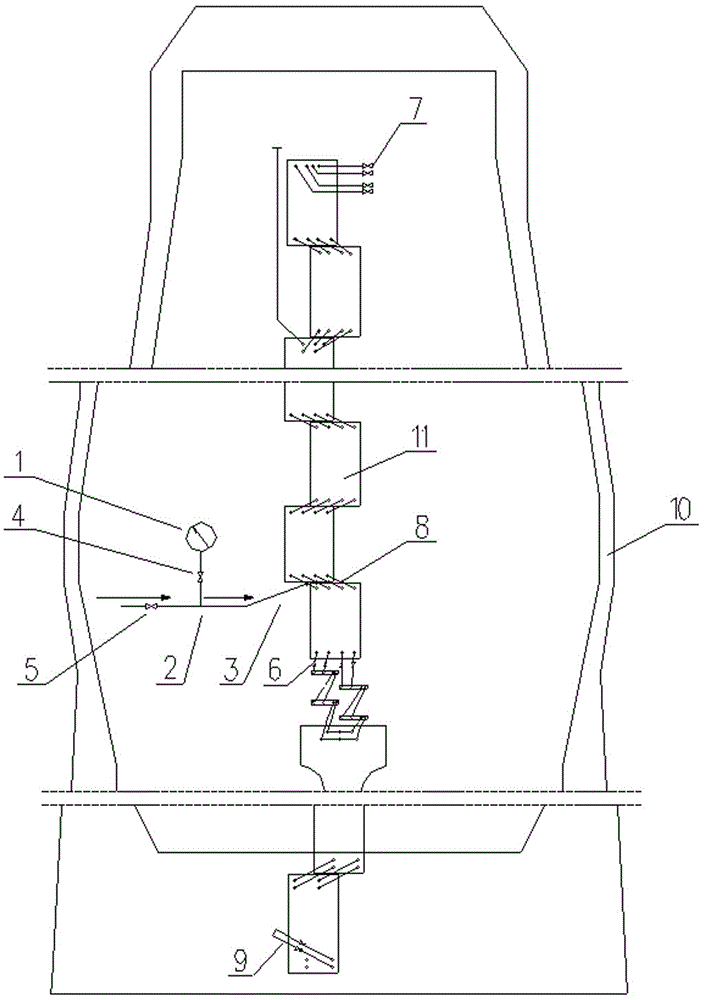

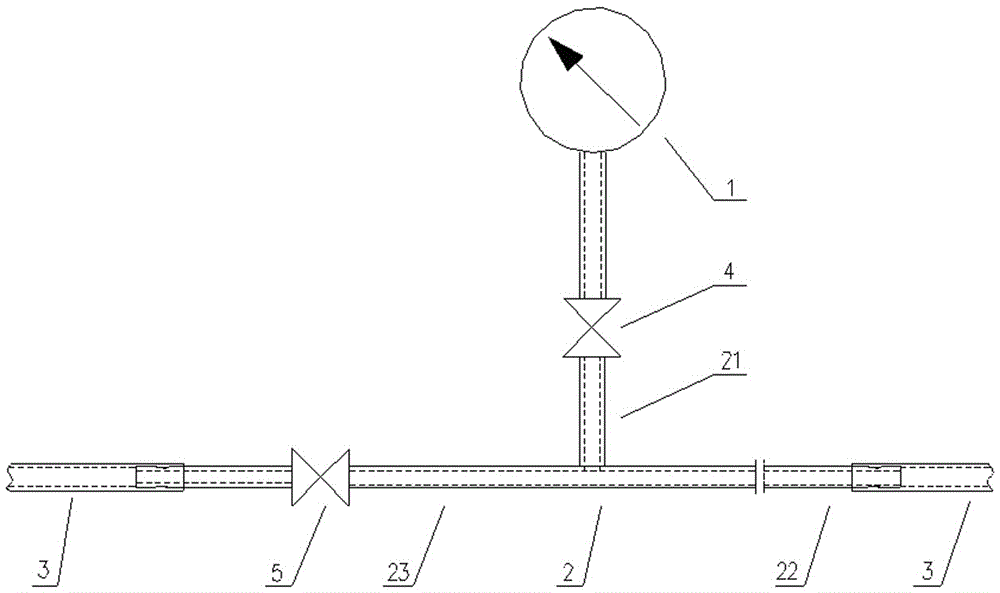

[0015] Such as figure 1 and 2 As shown, the leak checking device of the present invention comprises a pressure gauge 1, a three-way pipe 2, a connecting pipe 3, a pressure measuring valve 4, and a pressurizing valve 5, and the pressure measuring end 21 of the three-way pipe 2 passes through the pressure measuring valve 4 and The pressure gauge 1 is connected, the outlet end 22 of the three-way pipe 2 is connected to the blast furnace multi-stage connection closed circulation cooling water system through the connecting pipe 3, and the inlet end 23 of the three-way pipe 2 is connected to the connecting pipe 3 through the pressurization valve 5 Connected to pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com