A steel slag modification process in the dephosphorization stage of the converter

A converter and stage technology, applied in the manufacture of converters and other directions, can solve the problems of increasing FeO loss, single material function, increasing labor intensity, etc., and achieve the effects of improving fluidity, short slagging time, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

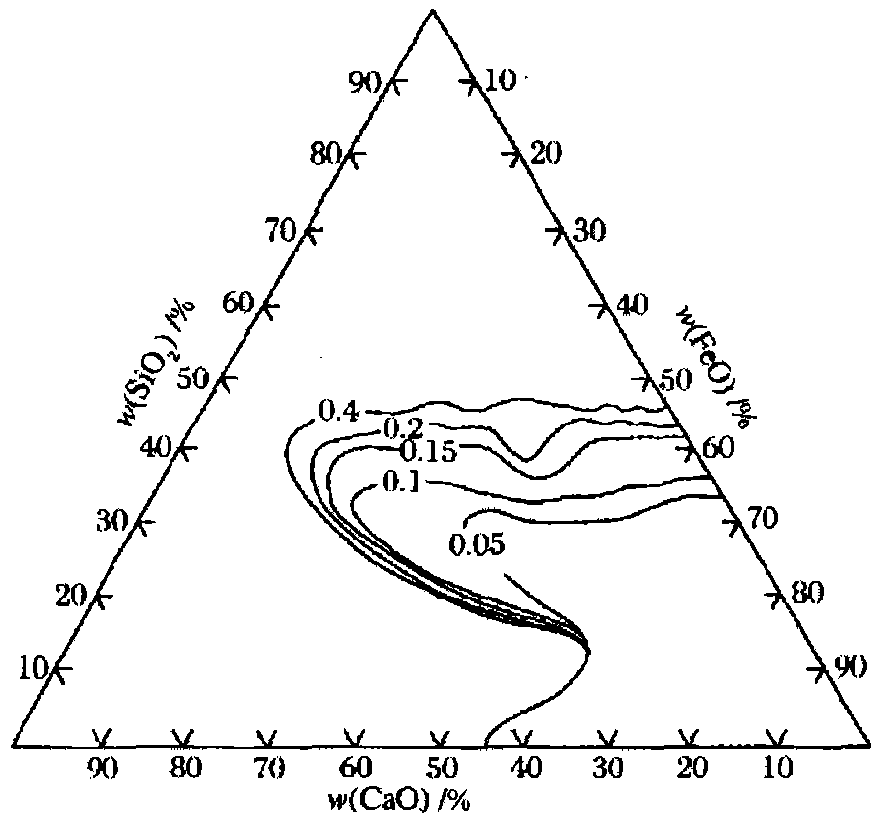

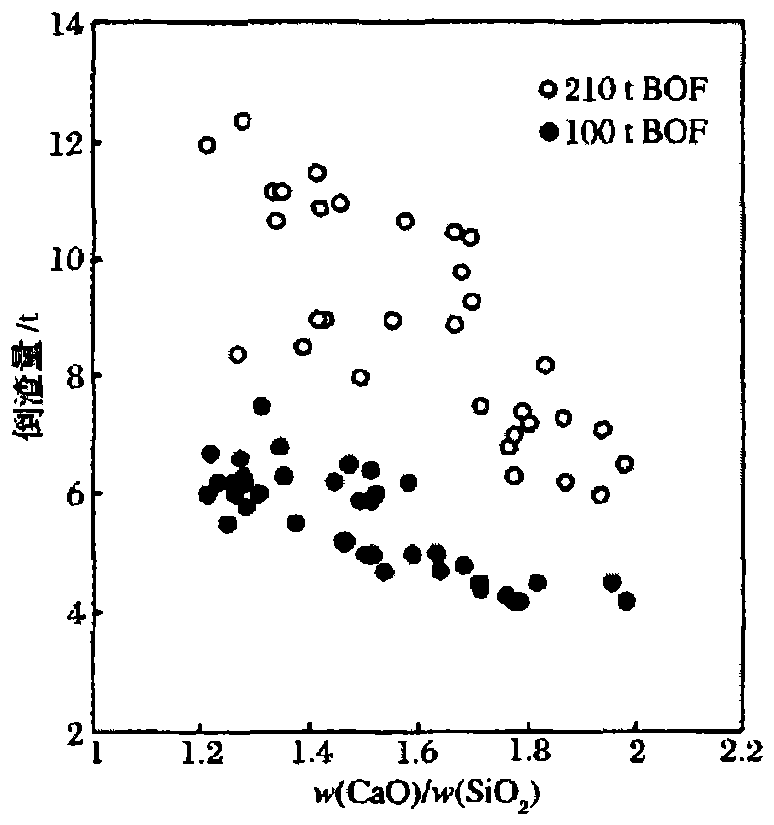

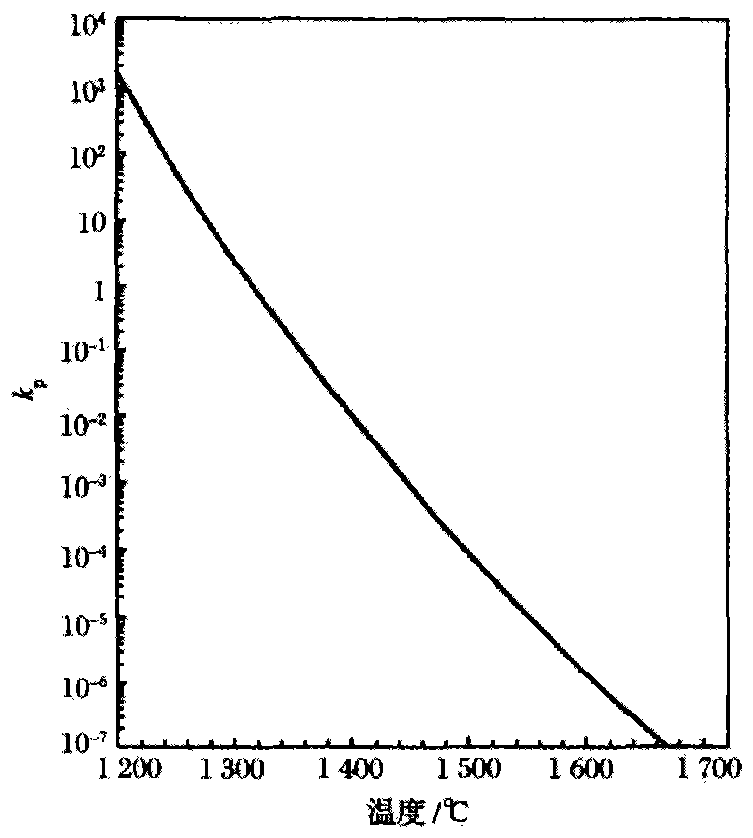

[0010] In the dephosphorization stage, control parameters such as slag alkalinity, MgO content, FeO content, and oxygen supply intensity to carry out blowing according to process requirements, and add SiO 2 material or SiO 2 and Al 2 o 3 as the main component material or Al 2 o 3 The material is used to modify the slag, so that the basicity of the slag is reduced to below 1.3 and above 0.8 after the converter stops blowing. In the actual production process, it is difficult to strictly control the basicity of slag within a certain range, either high or low. For the smelting mode where the slag basicity is higher than 1.5 in the dephosphorization stage, some SiO can be added at the end of blowing 2 material or SiO 2 and Al 2 o 3 Use the material as the main component to reduce the alkalinity of the slag to below 1.5 and above 1.3, and then add part of SiO to the furnace before or while lifting the gun after blowing is completed 2 material or SiO 2 and Al 2 o 3 As th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com