L-shaped prefabricated composite shear wall vertical anti-seismic connection node and construction method thereof

A technology for connecting nodes and shear walls, applied in the direction of walls, earthquake-proof, building components, etc., can solve the problems of limited ability to bear and transmit vertical and horizontal loads, low structural safety performance, etc., to achieve good integrity and ensure safety. Use, improve the effect of deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

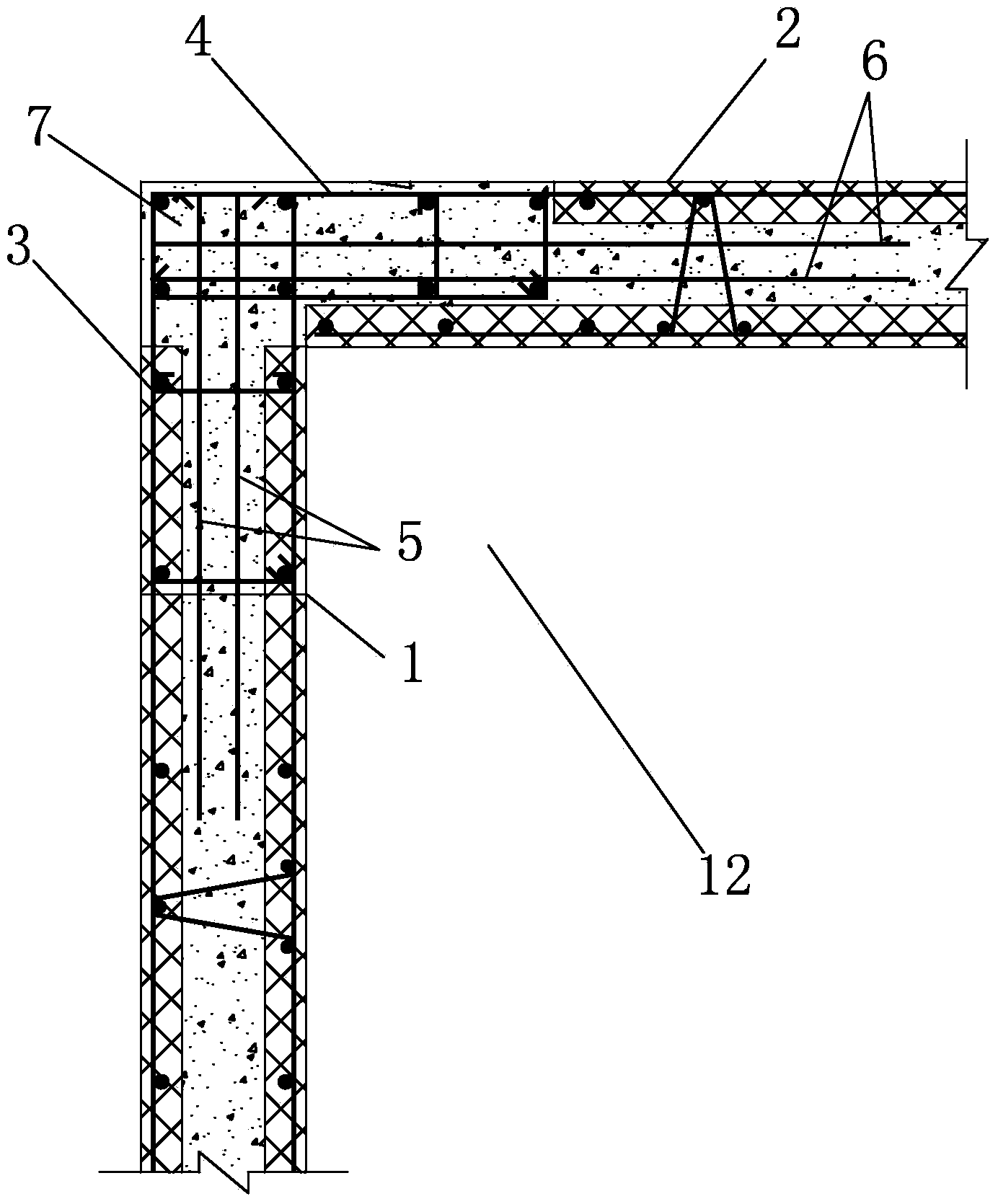

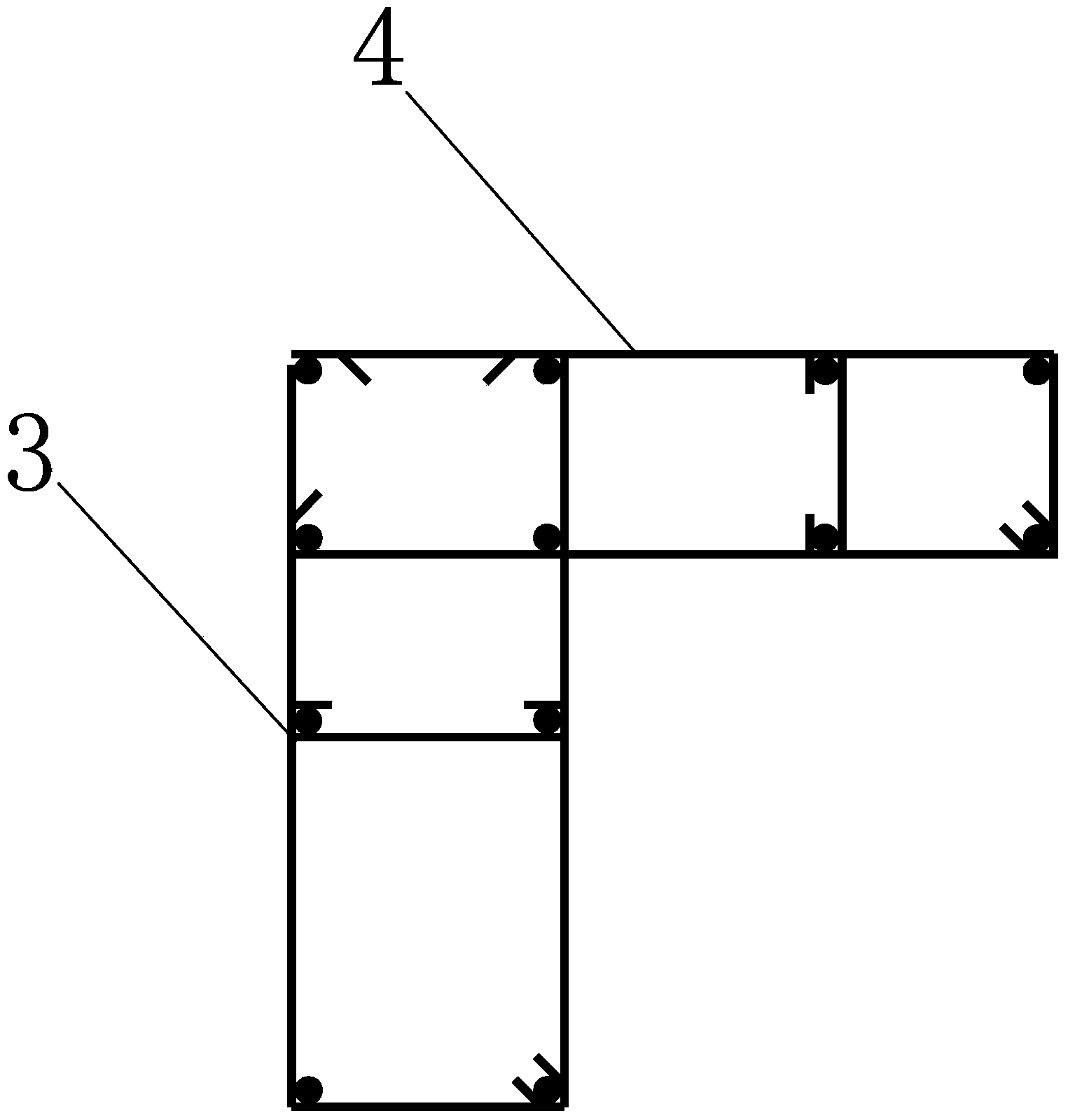

[0021] The present invention discloses an L-shaped vertical anti-seismic connection node of a laminated slab shear wall, which comprises a first prefabricated laminated slab shear wall 1 and a second prefabricated laminated slab shear wall 2 which are connected to each other. A plywood shear wall 12, the first prefabricated laminated slab shear wall 1 is provided with a first type stirrup cage 3 and a first insert 5, and the first insert 5 is installed in the first prefabricated laminated slab The joint between the shear wall 1 and the first-type stirrup cage 3; the second prefabricated laminated slab shear wall 1 is provided with a second-type stirrup cage 4 and a second inserting bar 6, and the second inserting bar 6 Installed at the junction of the second prefabricated laminated slab shear wall 1 and the second type stirrup cage 4; the first type stirrup cage 3 and the second type stirrup cage 4 are connected to each other; the first type stirrup cage 4 is connected to each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com