Universal booster capable of disengaging automatically without causing disturbance

A booster and non-disturbance technology, which is applied in the direction of jet propulsion devices, machines/engines, rocket engine devices, etc., can solve the problems of large quantity, divergent ammunition movement, and carrier disturbance, so as to increase the range of the carrier, reliable separation, and reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

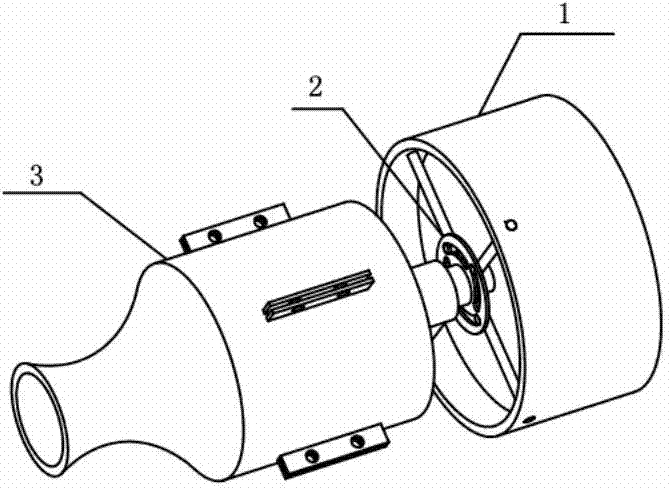

[0027] This embodiment is a kind of universal booster that comes off without disturbance automatically.

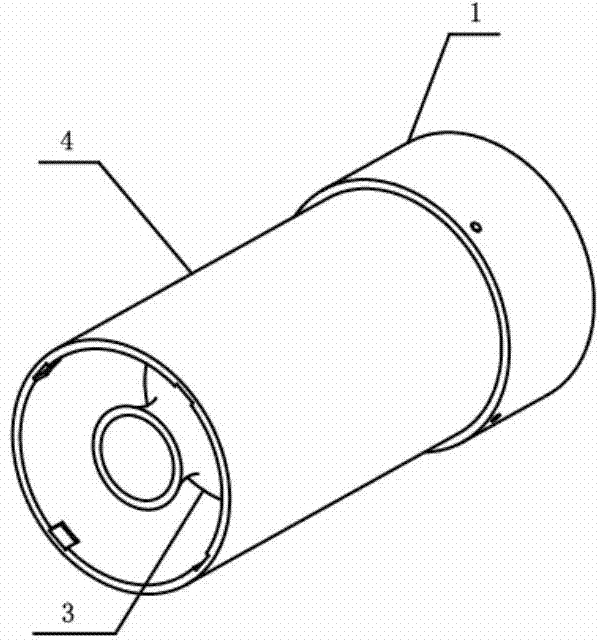

[0028] refer to Figure 1 to Figure 8 , the universal booster that falls off automatically without disturbance in this embodiment is composed of a locking and unlocking device 2, a rocket motor 3, a booster frame 4, and a carrier sleeve 1; the rocket motor 3 and the locking and unlocking device 2 are placed on the booster frame 4 inside; the booster frame 4 is fixedly connected with the carrier sleeve 1, and there are four uniformly distributed frame radial through holes 6 in the connecting section, and the locking and unlocking device 2 is inserted into the through holes to serve as positioning pins to realize the booster and The positioning of the carrier is fixed.

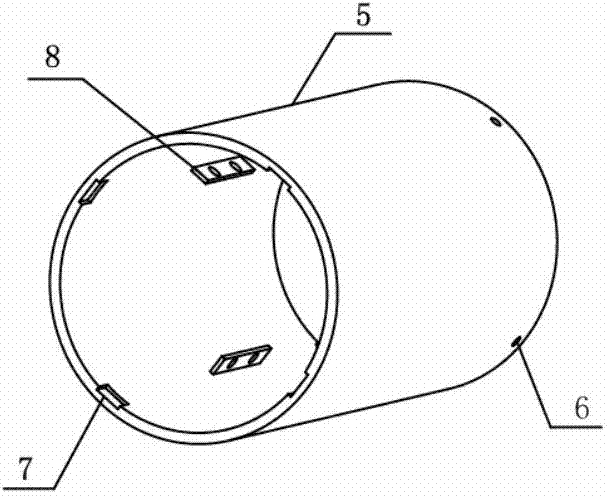

[0029] The booster frame 4 includes a frame shell 5, a frame radial hole 6, an impact cover groove 7, a frame lug 8, a frame groove 9, and a central hole 10. The booster frame 4 is a cylindrical shell, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com