Manual adjusting arm

A technology for manual adjustment and adjustment of the shaft, applied in the field of manual adjustment arms, can solve the problems that the adjustment end is easily eroded by mud and water, the worm is difficult to rotate, and the instability is high, and the structure is simplified, the adjustment accuracy is guaranteed, and the stability is strong.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

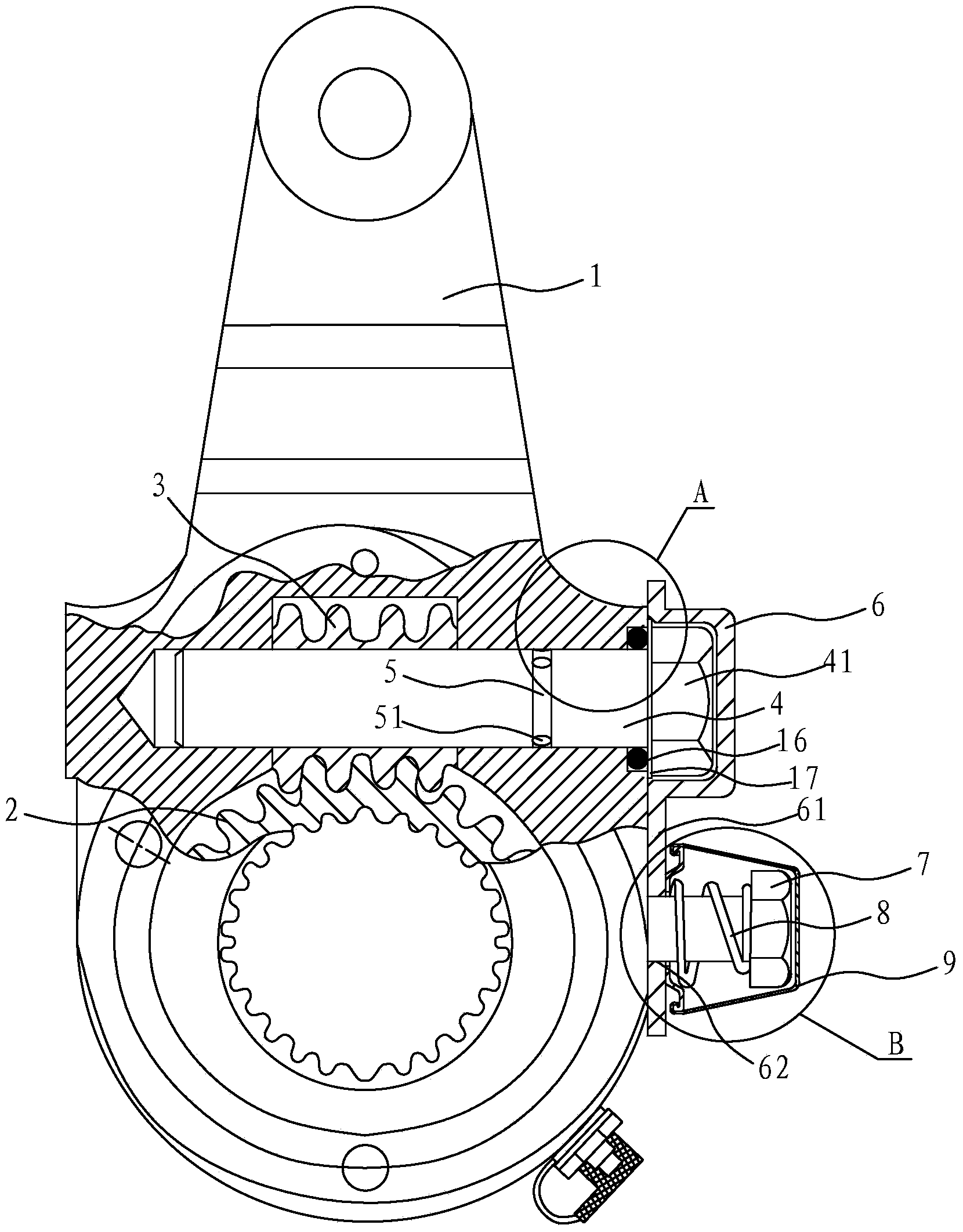

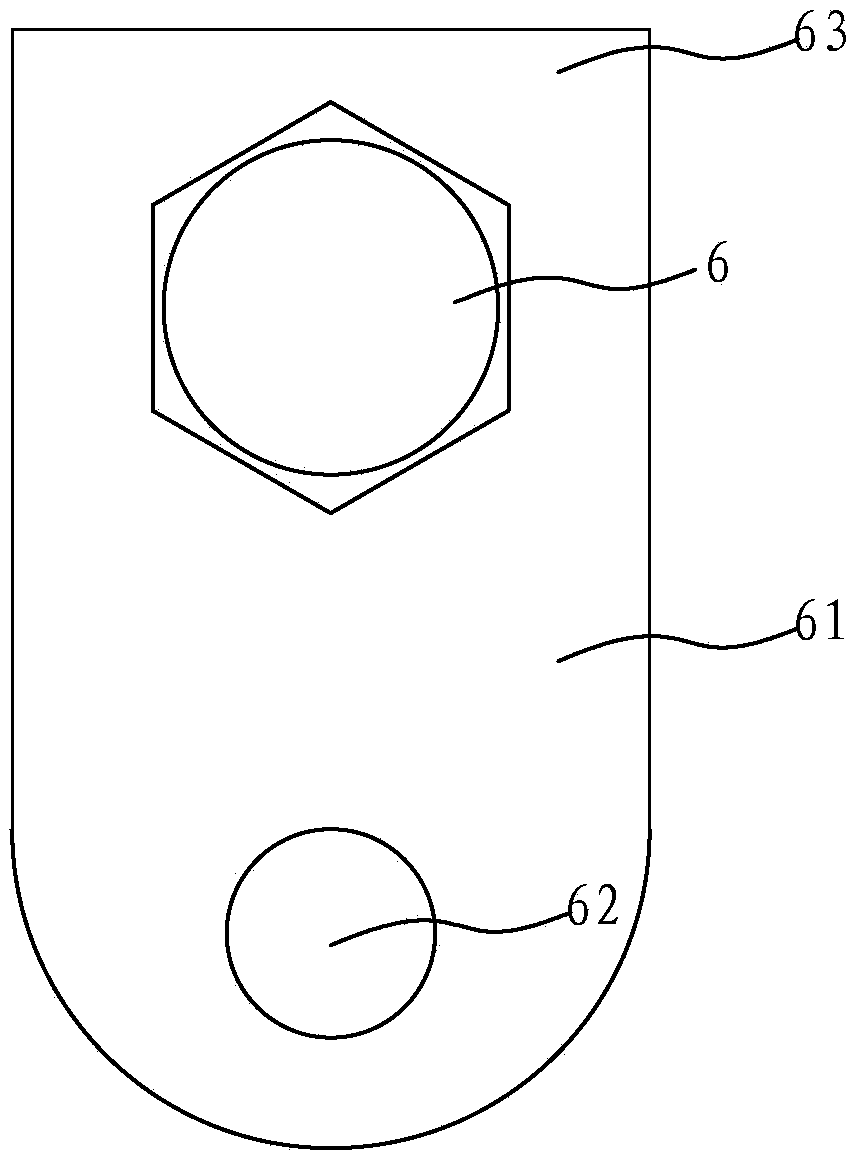

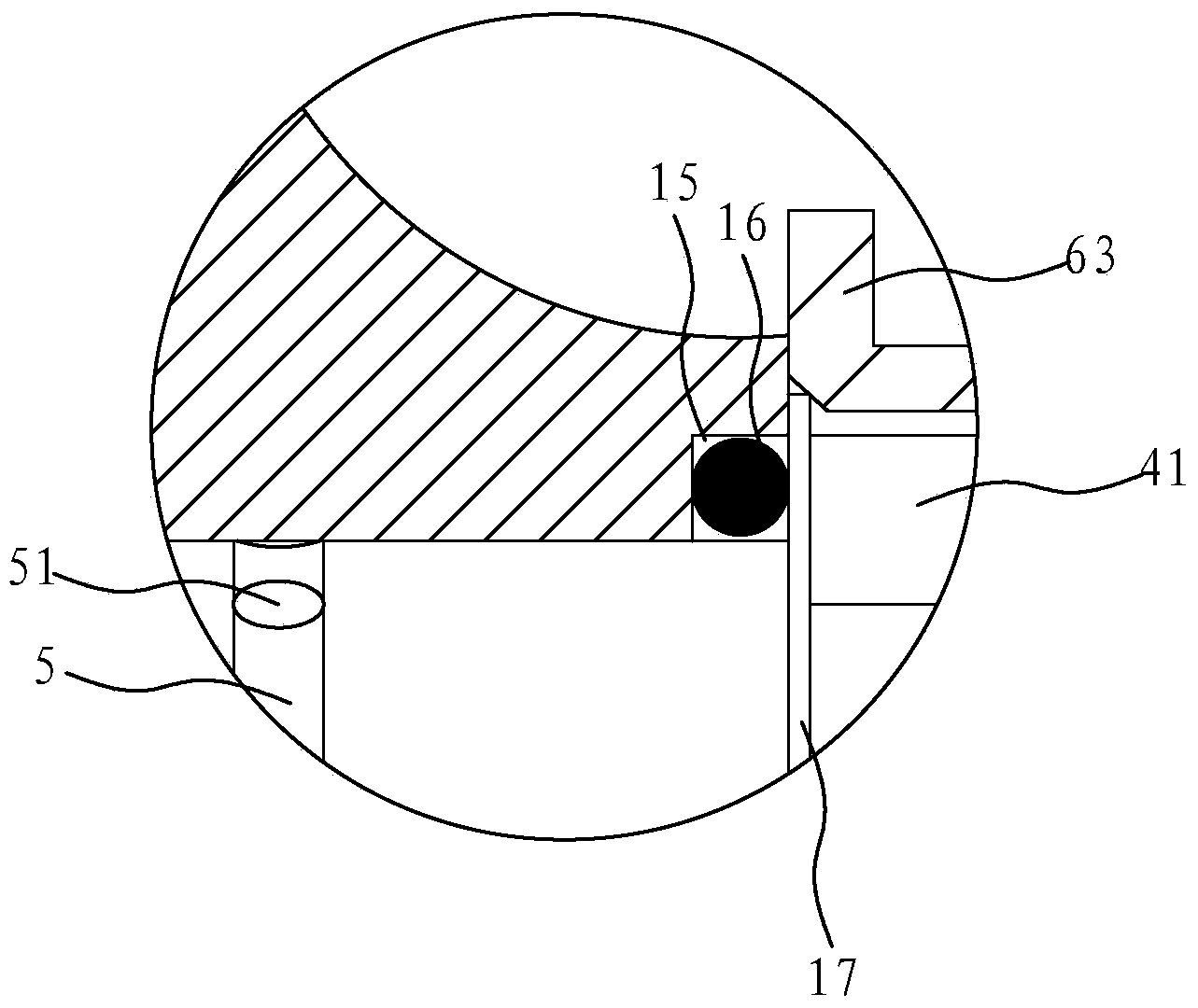

[0023] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , this embodiment provides a kind of manual adjustment arm, including a housing 1, a worm wheel 2 installed in the housing 1, a worm 3 located in the housing 1 and engaged with the worm gear 2, and a Adjustment shaft 4, the end of the adjustment shaft 4 passing through the housing 1 is provided with an adjustment terminal 41, the front and rear ends of the housing 1 are respectively provided with sealing plates 12 for covering the turbine 2, the housing 1 The outer wall is provided with a cap 6 that can be used to cover and seal the adjustment end 41 to prevent dust and looseness. A connecting plate 61 extends from the cap 6, and a fixing hole 62 is provided on the connecting plate 61. The cap 6 is fastened on the housing 1 by passing through the fixing hole 62 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com