Lighting fixture for a vehicle

A technology for illuminators and lighting appliances, which is applied in the field of illuminators and can solve problems such as complex and uneven photoconductor components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

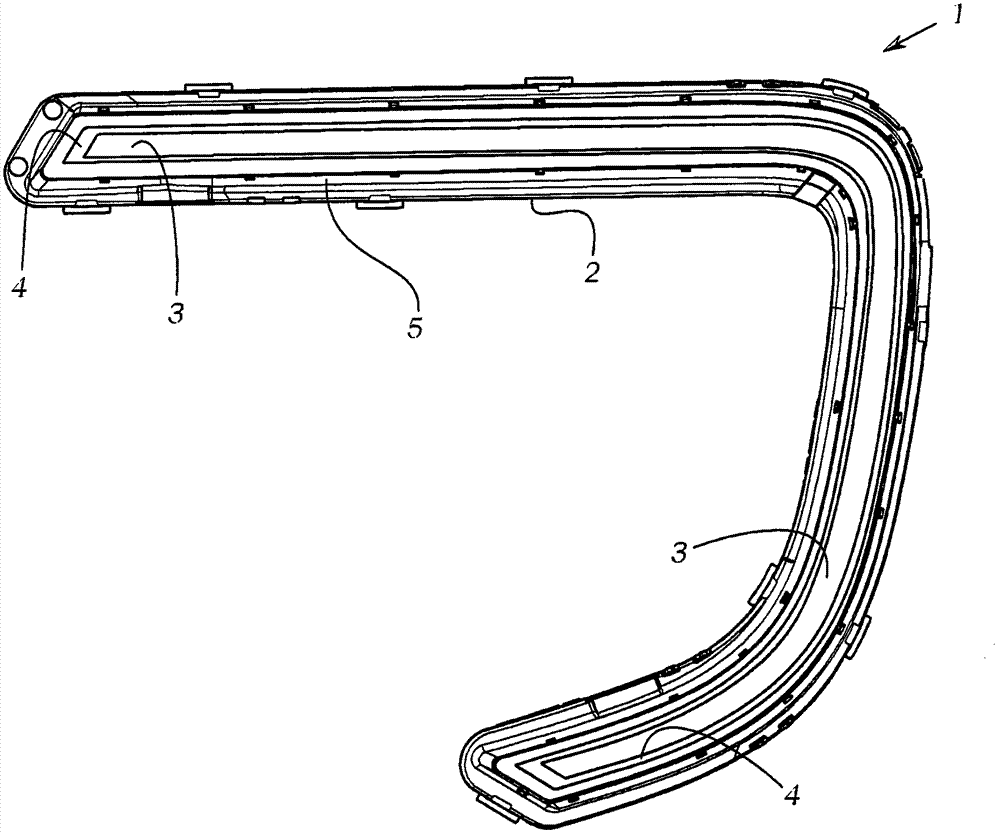

[0023] exist figure 1 In the luminaire according to the present invention Labeled with 1. The illuminant 1 essentially consists of a base body 2 , a light conductor element 3 , a clamping element or baffle 4 and a cover 5 , wherein the base body 2 can be attached, for example, to a vehicle bumper by means of a fastening device not shown further. It is connected or can also be formed integrally with the bumper in order to emit light over the entire length of the light conductor element 3 .

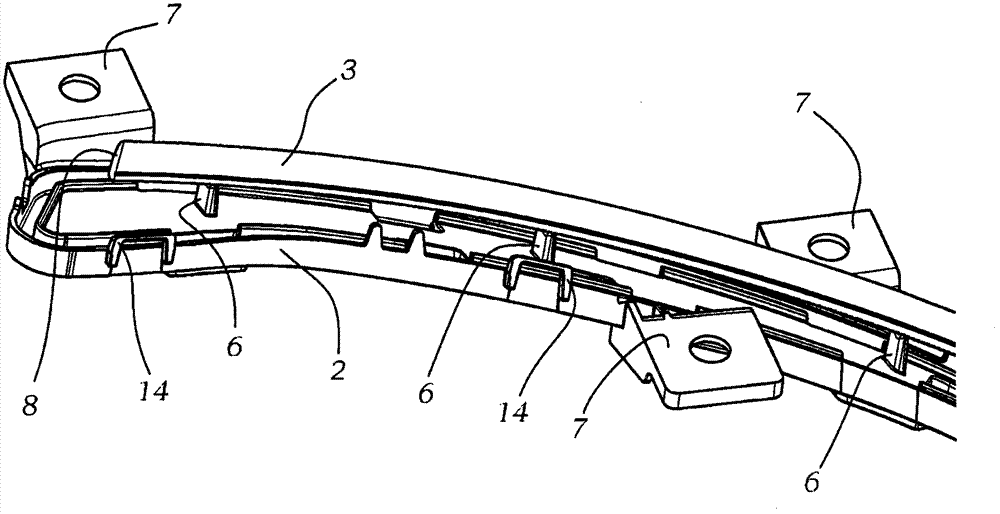

[0024] exist figure 2 Only the base body 2 and the light conductor element 3 are shown in , and it can be seen that the light guide element 3 rests on a carrier element 6 formed on the base body 2 . The fixing device of the luminaire 1 is marked with 7 . The end faces of the light conductor element 3 are marked with 8 .

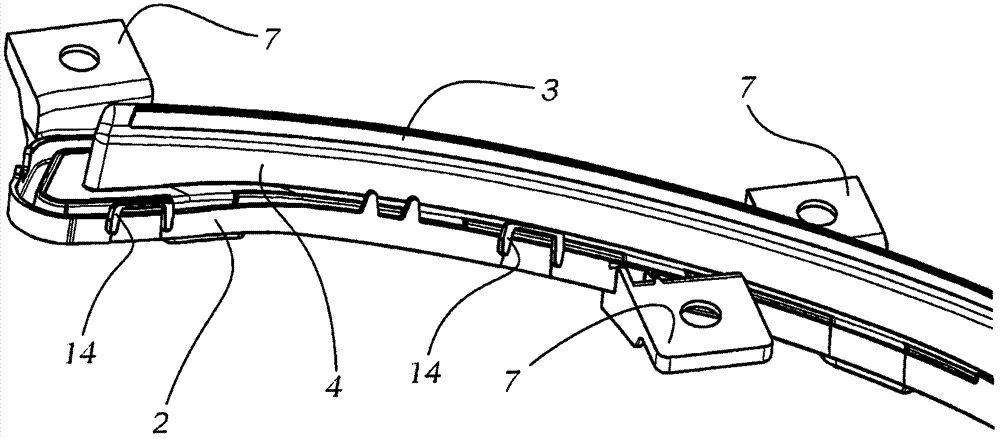

[0025] image 3 corresponds to figure 2 , except for one difference that the clamping element or baffle 4 is mounted on the base body for fixing the light conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com