Single-channel internally-arranged type heat exchanger sheet bar

A heat exchanger, built-in technology, applied in the field of built-in heat exchanger plates, can solve the problems of inconvenient cleaning and maintenance, low efficiency, slow heat transfer speed, etc., achieve convenient and flexible use, improve heat exchange efficiency, and evenly distribute Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

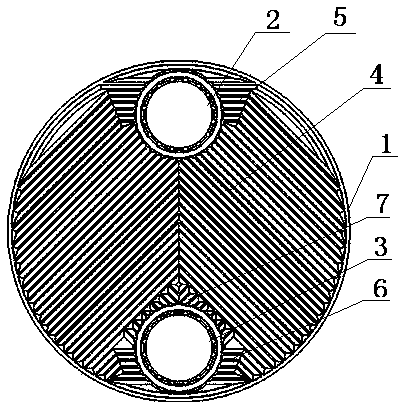

[0007] Depend on figure 1 The single-channel built-in heat exchanger plate shown is that the inlet corner hole 2 and the outlet corner hole 3 are distributed above and below the circular plate 1, and at the same time, the center line connecting the two corner holes 2 and 3 is the symmetrical center, and the intersection Symmetrical oblique corrugations 4 inclined to both sides at the center of symmetry. The bilateral symmetrical oblique corrugations 4 are 90° to each other. On both sides of the two corner holes 2 and 3, distribution sections 5 and 6 composed of horizontal areas are arranged respectively, and an angular diversion section 7 is also arranged outside the outlet corner hole 3 .

[0008] The use of the present invention is to use the plates (such as figure 1 As shown) 1 rotates 180° horizontally, then flips down 180°, and then with another plate (with figure 1 The same as in the above) 1 The periphery is welded by argon arc welding to form a pair of plates, and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com