Downhole tool ground milling test system and downhole tool milling method

A technology for downhole tools and test systems is applied in the field of ground milling test systems for downhole tools, and achieves the effects of simplified experiments, easy movement, and regular shapes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

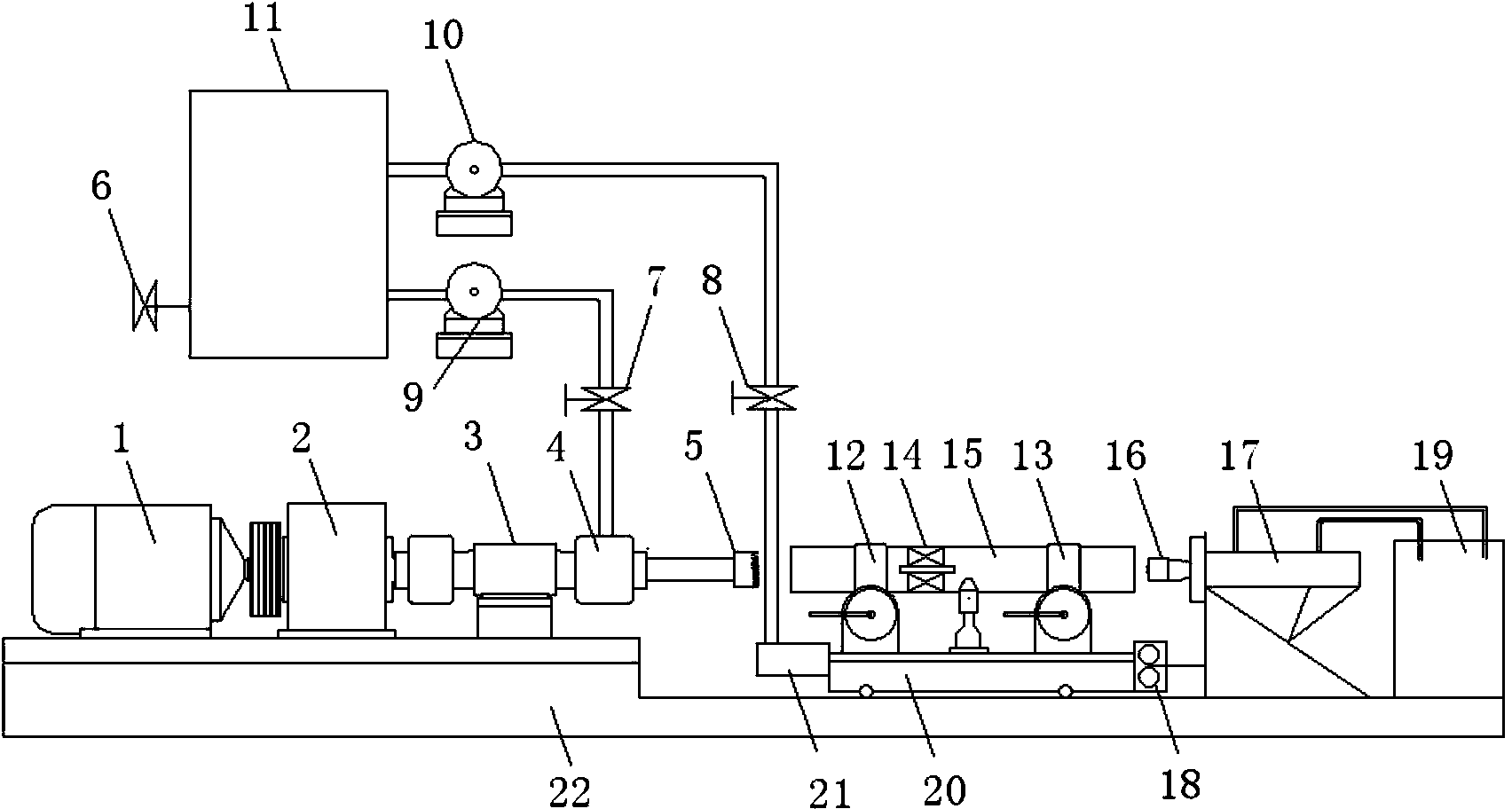

[0035] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

[0036] Such as figure 1 As shown, the present invention proposes a ground milling test system for a downhole tool, which is used to perform a milling test on a downhole tool 14 arranged in a casing. The downhole tool 14 includes, for example, a center pipe and a bridge plug sleeved outside the center pipe. , the present invention provides reliable data guidance for actual construction operations by simulating the grinding and milling of downhole tools on the ground before actual construction operations.

[0037] The ground milling test system for downhole tools includes:

[0038] A power drive system for milling the downhole tool 14, a milling load adjustment system for pushing the downhole tool to move horizontally, and a computer measurement and control system for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com