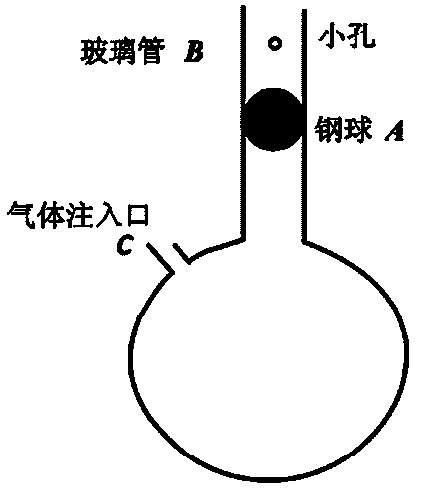

Method for measuring air specific heat ratio through the adoption of vibration method

A technology of specific heat capacity ratio and vibration method, applied in the direction of analyzing materials, instruments, etc., can solve the problems of difficulty in realization, uncertainty, non-uniform surface of steel ball A, etc., and achieve the effect of simple structure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

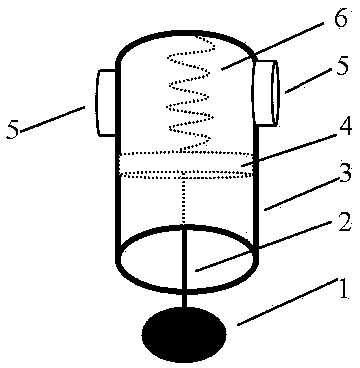

Embodiment Construction

[0013] A cylinder 3, the upper end of which is sealed and the lower end is open. The outer upper end surface of the cylinder 3 is a plane, and the plane is perpendicular to the axis of the cylinder 3 (made by the manufacturer and guaranteed to be vertical), and there is a Horizontal bubbles, the upper end of the side of the cylinder 3 has one or two or more air holes 5, the air holes 5 can be sealed by the sealing nut (the opening end of the air hole 5 is close to one side of the gasket, and the other side of the gasket is connected to the The inner side of the sealing nut is tightly contacted to achieve sealing); the cylinder 3 is vertically fixed on the support, and the vertical fixing cylinder 3 can be welded with a screw on the upper end of the cylinder, the screw penetrates into the screw hole of the support, and then is fixed by the nut. Or adopt other commonly used fixing methods, such as the cylinder 3 is clamped and fixed on the support by a clamp, adjust the height ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com