Test system and test method for insulation safety equipment for extra-high voltage live working

A technology of insulation safety and live work, applied in the direction of instruments, measuring electricity, measuring electrical variables, etc., can solve the problems of increasing the risk of test operators, no safety protection system, and poor voltage equalization effect, so as to ensure the accuracy and accuracy of the test performance, improvement of test efficiency, and reduction of corona noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

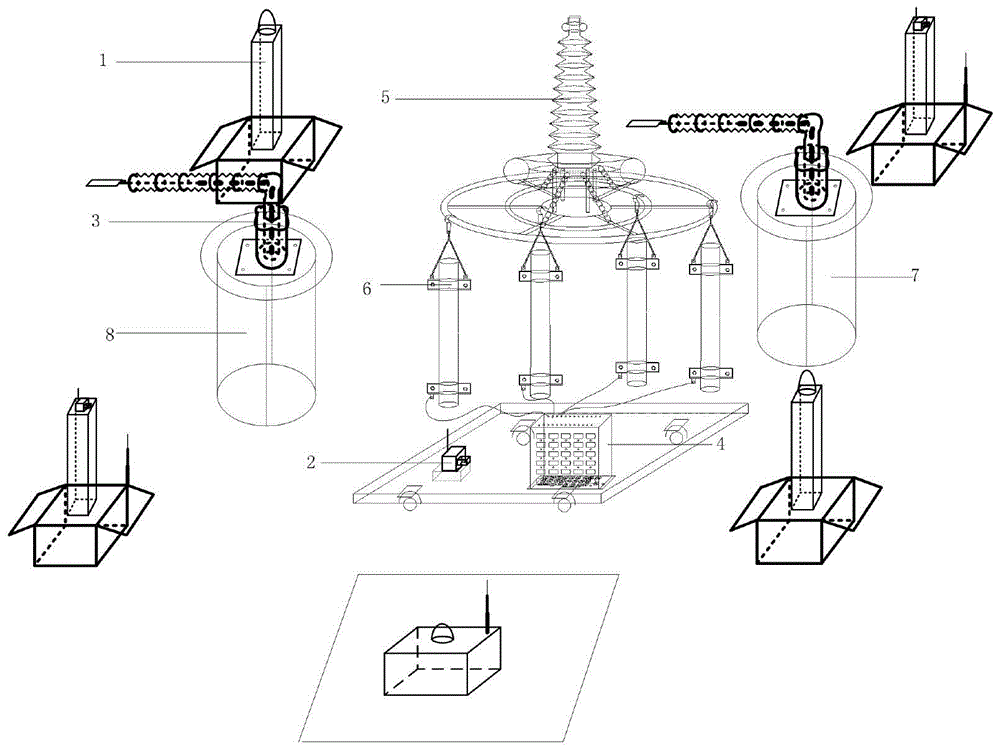

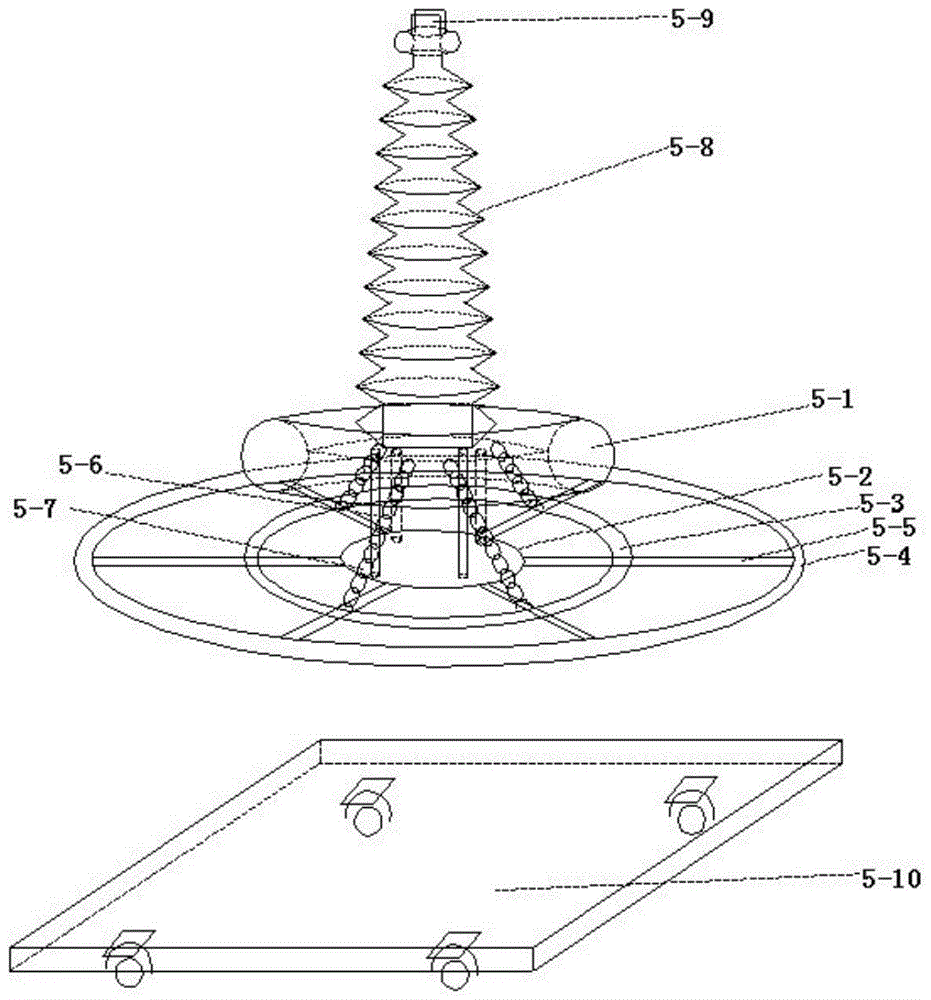

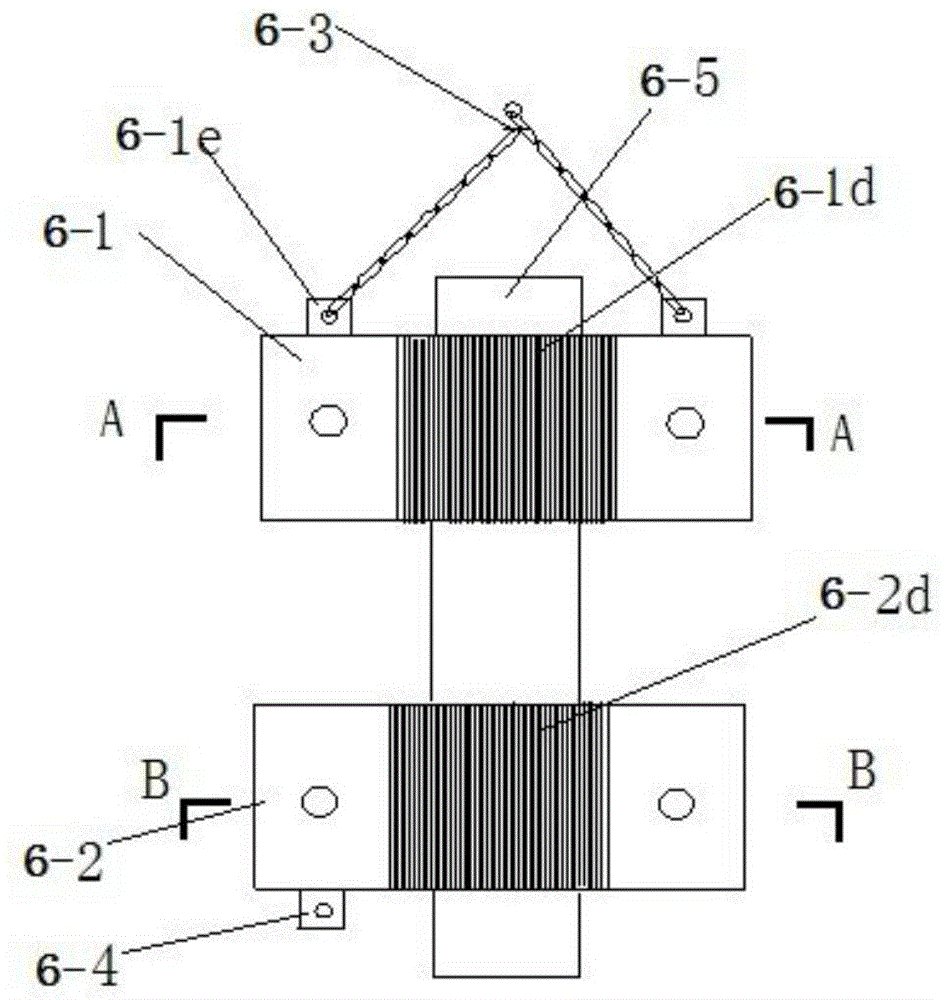

[0034] Such as figure 1 As shown, the ultra-high voltage live working insulation safety tool test system of the present invention includes a test suspension device 5 for super high voltage live work insulation safety tools, and a group of insulation devices for clamping the tested product 9 suspended on the suspension device 5. Rod arc-shaped iron clamp test electrode 6, an infrared intelligent high-voltage test protection system 1 with wireless monitoring function arranged on the periphery of the suspension device 5, a remote acquisition device 2 for test data in an ultra-high voltage test electric field environment arranged below the suspension device 5 and Leakage current centralized measurement device 4, power frequency test transformer 7 and impulse voltage generator 8 respectively arranged on both sides below the suspension device 5, ultra-high voltage test rotary telescopic device respectively arranged on the top of power frequency test transformer 7 and impulse voltage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com