Optical attenuator of wave length related loss compensation and compensation method

A wavelength-dependent and loss-compensating technology, applied in the coupling of optical waveguides, light guides, optics, etc., can solve problems such as difficult to low and inability to provide different compensation amounts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

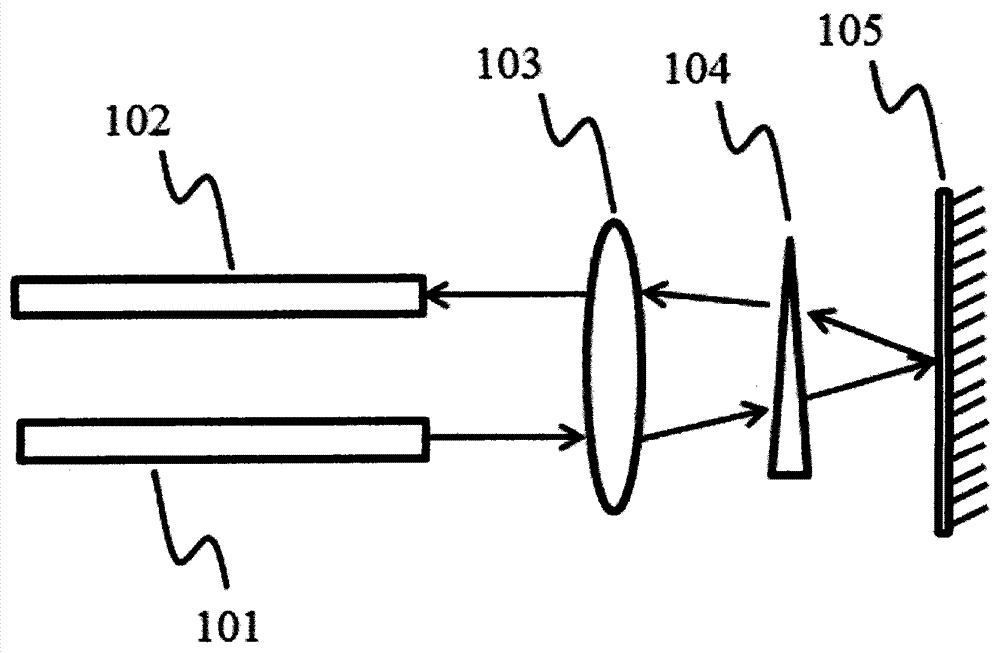

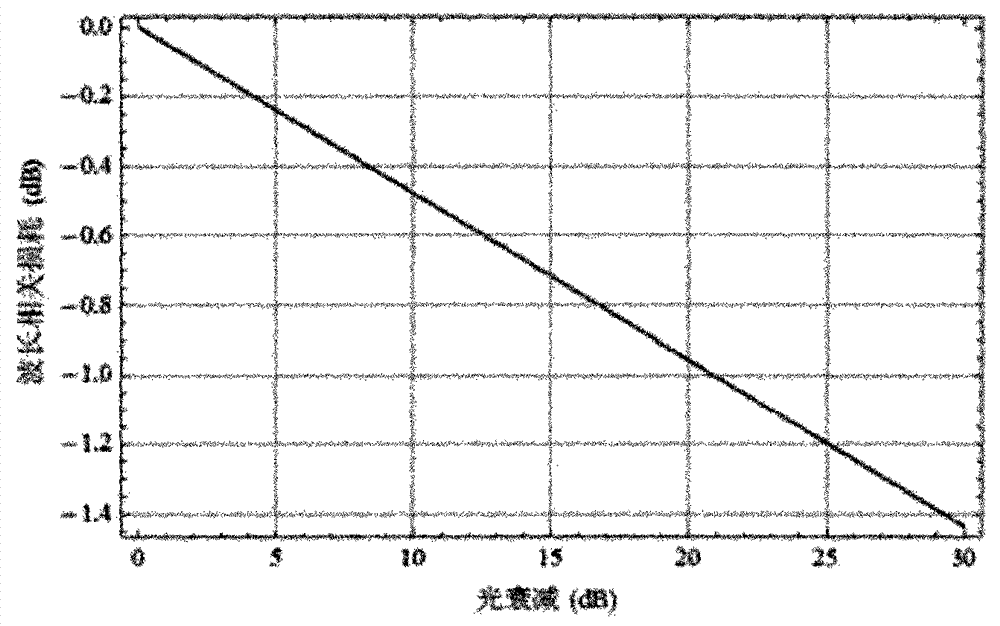

[0068] An embodiment of an optical attenuator for compensating wavelength-dependent loss provided by the present invention, such as Figure 5a (top view) and Figure 5b (Side view), including:

[0069] An input optical waveguide (501) for inputting optical signals;

[0070] An output optical waveguide (502) for outputting optical signals;

[0071] a collimating lens (503) having a first focal plane (522) and a second focal plane (523);

[0072] a mirror (505) having an axis of rotation (521) rotatable about said axis of rotation;

[0073] A phase layer is composed of independent phase plates (504).

[0074] The input optical waveguide and the output optical waveguide are located on the first focal plane of the collimating lens, and the mirror is located on the second focal plane of the collimating lens; the phase plate is located between the first focal plane and the collimating lens, close to input optical waveguide and output optical waveguide,.

[0075] The input opti...

Embodiment 2

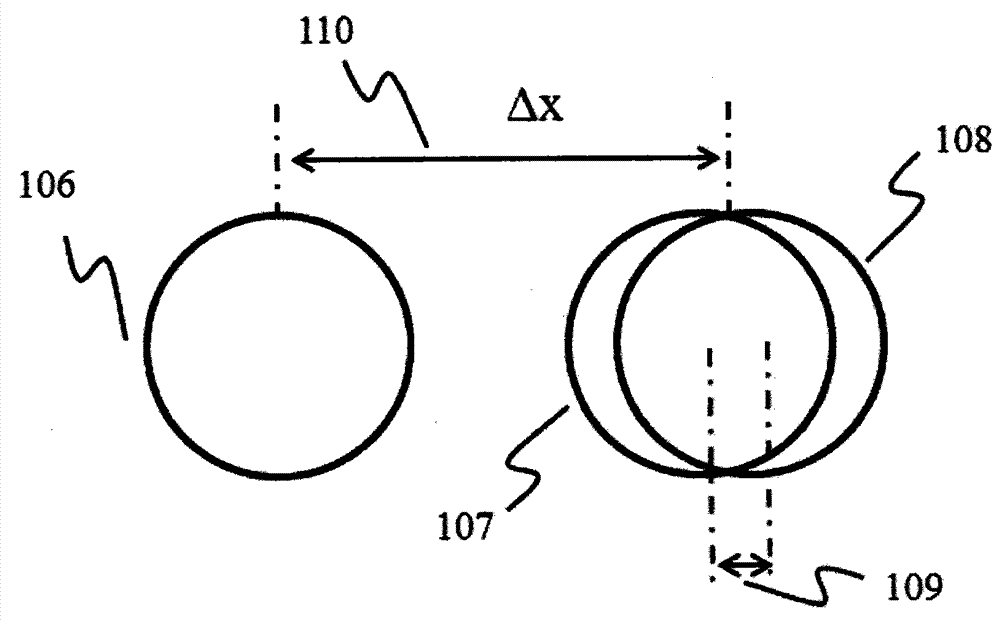

[0086] The 2nd embodiment of the present invention is similar to embodiment 1, as Figure 6a and 6b As shown, the difference is that the phase layer (604) is directly formed on the end faces of the input optical waveguide (601) and the output optical waveguide (602) by means of optical coating. The interface (610) between the first optical area (607) and the second optical area (608) can be a straight line or a circle or an annulus.

Embodiment 3

[0088] The 3rd embodiment of the present invention is similar to embodiment 1, as Figure 7 As shown, the difference is that the phase layer (704) is spliced by two optical glasses with different refractive indices. For example, the first optical region (707) adopts optical glass bk7, and the second optical region (708) adopts fused silica. The refractive index difference between the two is about 0.056 in the 1.55 micron wavelength band commonly used in communication. It can be achieved by increasing the thickness (709)t The required optical path difference OPD, OPD is described by the aforementioned formula (10). The interface (710) between the two optical materials needs to be flat enough to avoid unwanted scattering when the light spot passes through. The optical substrate (706) is not necessary in terms of optical effects, it plays a role of supporting the optical materials used in the thinner first and second optical regions, and one of two types of optical glass can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com