Apparatus for decanting supernatant liquid contained in a clarifier

A technology of clarifier and clear liquid, which is applied in the direction of feeding/discharging devices, instruments, liquid level control, etc. of the settling tank, which can solve problems such as controller damage, and achieve low complexity and robustness in manufacturing and assembly Good, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

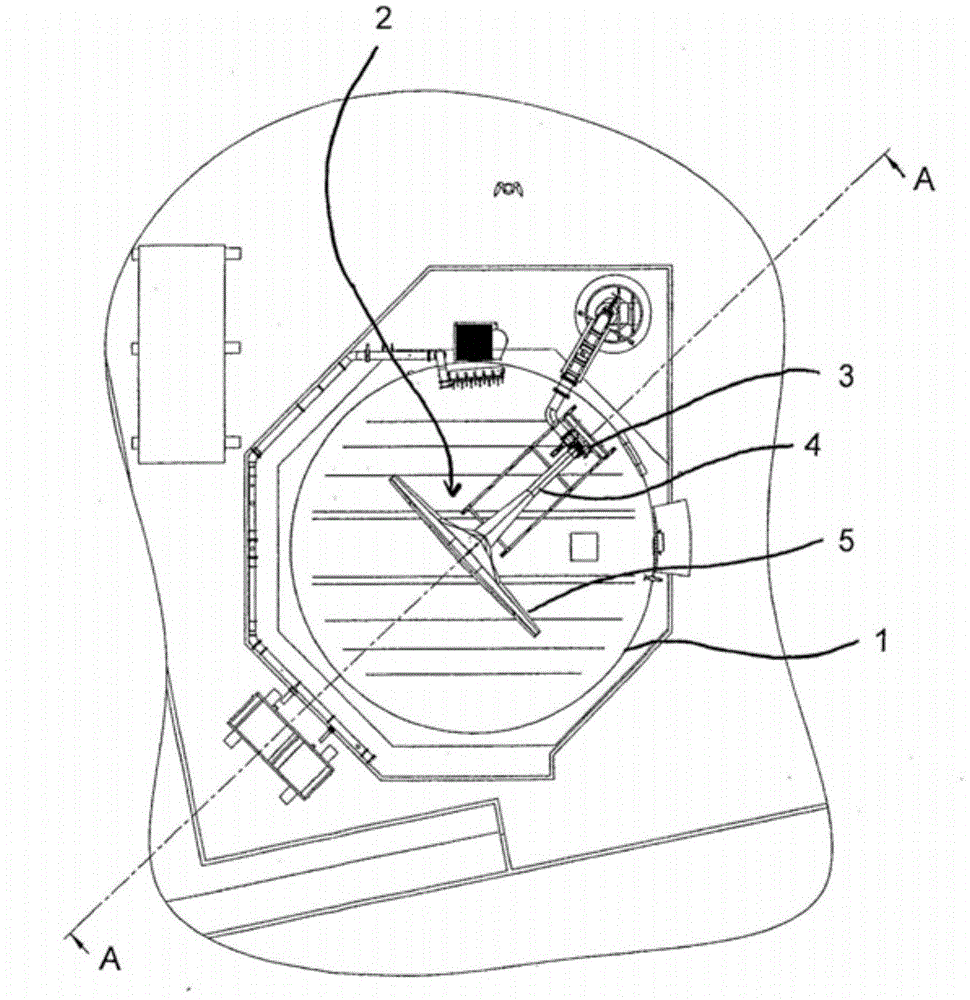

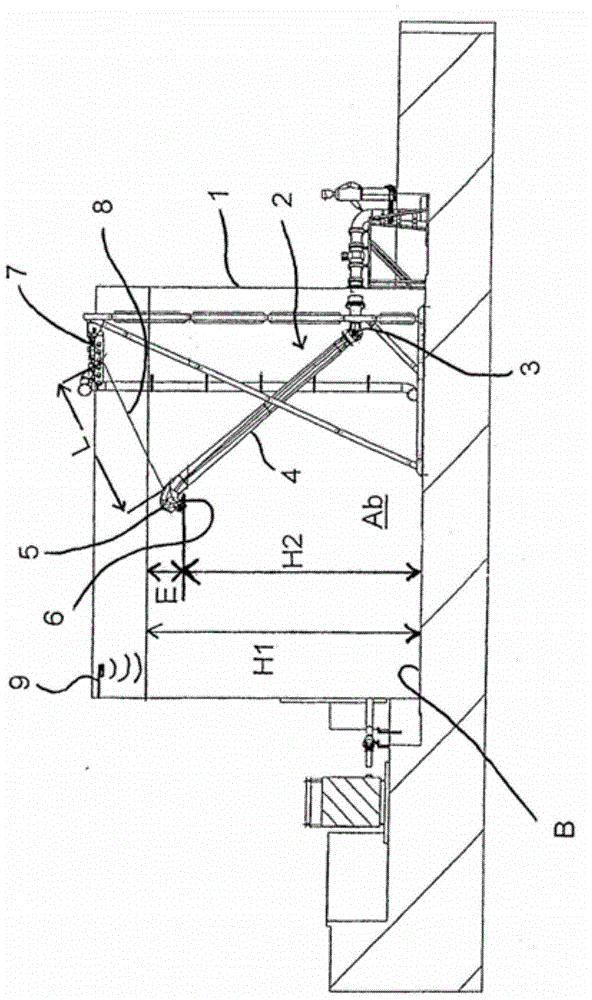

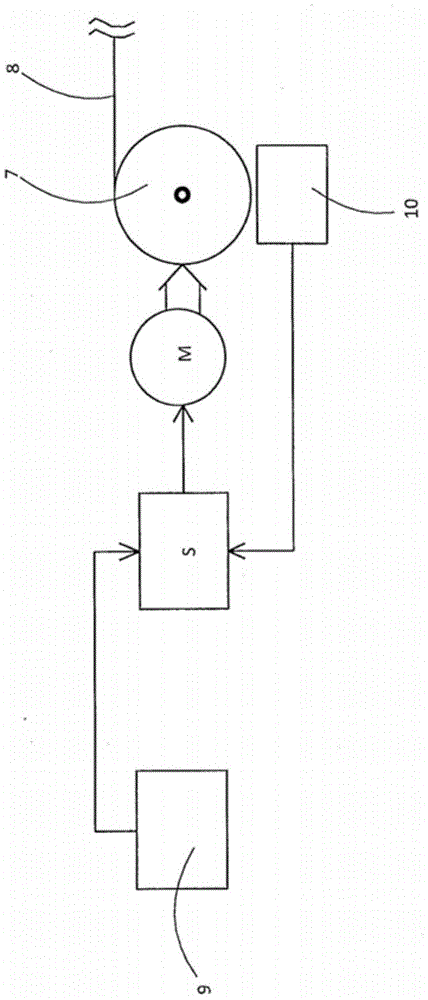

[0053] exist figure 1 and 2 , one end of the decanter 2 is pivotally held on a pivot bearing 3 in the clarifier 1 . The decanter 2 has a pipe 4 extending from the pivot bearing 3, and a decanter head 5 provided at the other end of the pipe 4 and extending perpendicular thereto. On the underside of the decanter head 5 facing the bottom B of the clarifier 1 there is a slit-shaped water inlet 6 . Reference numeral 7 denotes a winch on which a cable 8 connected to the decanter head 5 is taken up. The reference L designates the length of the actuator of the cable 8 . The length L describes the corresponding distance between the decanter head 5 and the pivoting device or capstan 7 .

[0054] Reference numeral 9 denotes a first measuring device for measuring the filling level H1 of the waste water Ab contained in the clarifier 1 . The first measuring device may be an ultrasonic or radar measuring device. The distance between the water inlet 6 and the bottom B is indicated by re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com