Novel factory type recirculating aquaculture system

A new type of circulating aquaculture technology, which is applied in fish farming, climate change adaptation, application, etc., can solve the problems of large volume, large floor area, and high cost of biological filters, and achieve cost reduction, safe and stable operation, and low cost. The effect of a small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

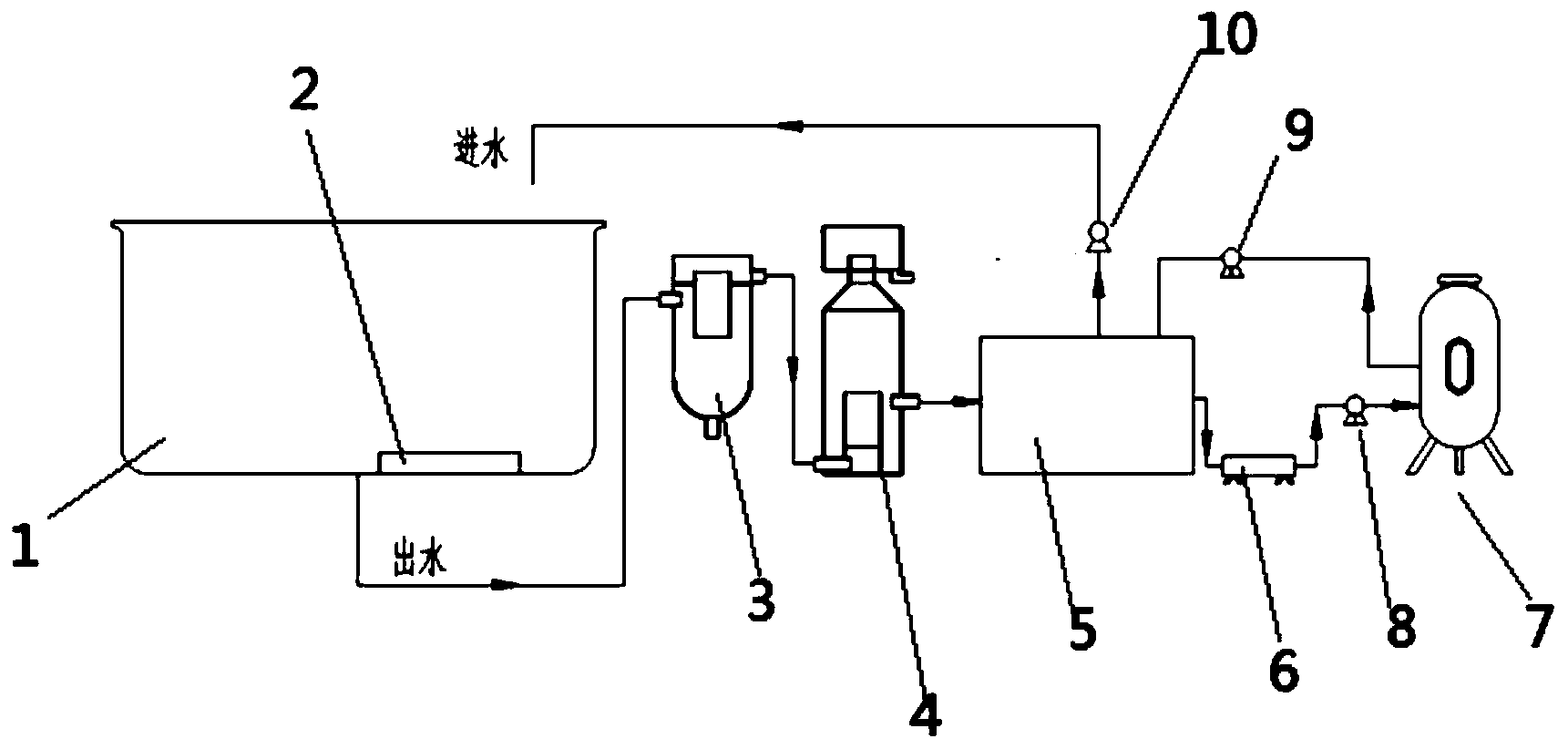

[0017] A novel industrialized circulating aquaculture system, comprising a fish pond 1, the fish pond is provided with a water outlet, the water outlet communicates with a vertical flow sedimentation device 3, the vertical flow sedimentation device 3 communicates with a protein separator 4, the The protein skimmer 4 is communicated with the adjustment tank 5, and the first water outlet of the adjustment tank 5 is communicated with the water inlet at the upper end of the fish pond 1 through the circulation pump 10; it also includes a fermenter 7, which is beneficial to the cultivation of fish in the fermenter 7. The fungus of growth, its upper liquid outlet is communicated with regulating pond 5 by metering pump 9, and the second water outlet of regulating pond 5 is communicated with the lower liquid inlet of fermentor by ultraviolet sterilizing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com