A kind of automatic black tea primary production system

A production system and technology for black tea, applied in the field of automatic black tea primary production line, can solve the problems of low efficiency of production system and low degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

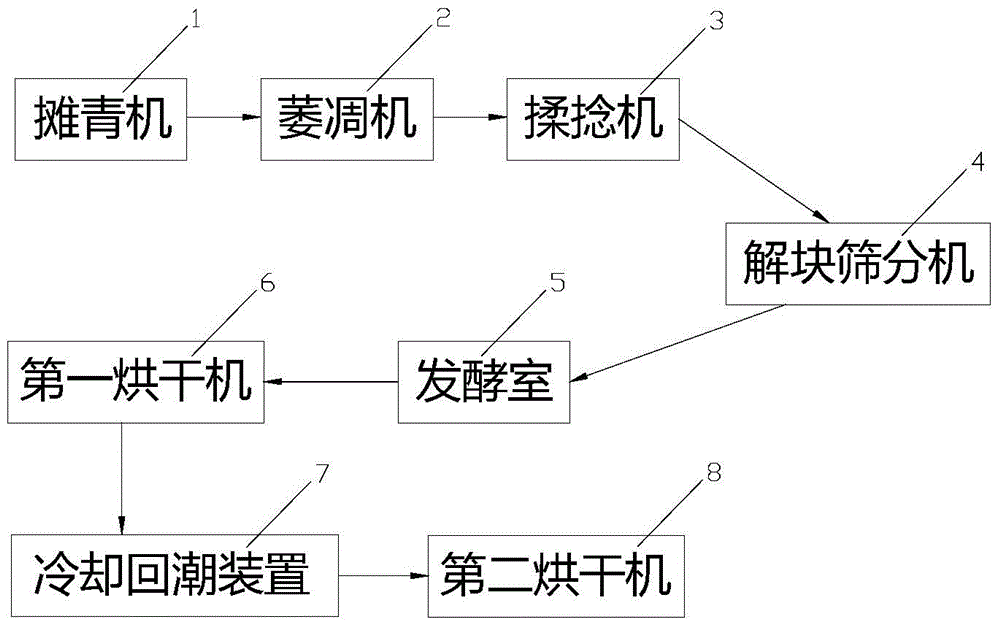

[0033] See figure 1 , An automated black tea preliminary production system, which includes a green spreading machine 1, a withering machine 2, a twisting machine 3, a deblocking and screening machine 4, a fermentation chamber 5, a first dryer 6 and a second drying machine connected in sequence. The machine 8 is also provided with a cooling and moisture regaining device 7 between the first dryer 6 and the second dryer 8; it also includes an automatic control unit for controlling the temperature, humidity and air volume of the production system.

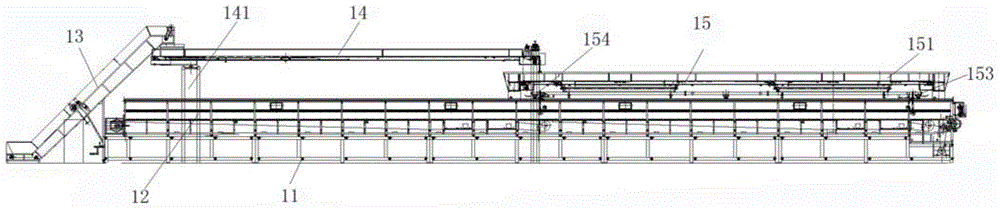

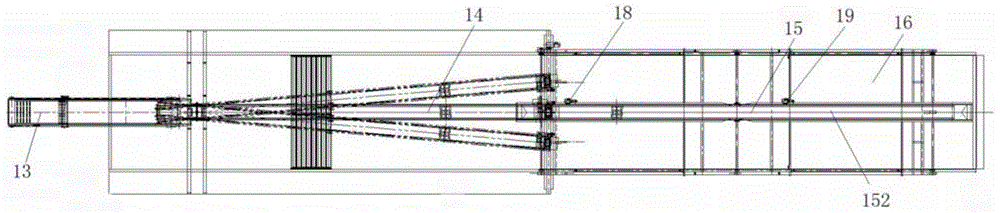

[0034] See Figure 2 to 5 , The green spreading machine 1 includes a frame 11, a main box 12 arranged on the frame 11, a first lifting mechanism 13 installed at the front of the frame 11, and a first plane conveying mechanism 14 connected to the first lifting mechanism 13 , And a movable second plane conveying mechanism 15 arranged below the first plane conveying mechanism 14; the main box 12 is provided with a first conveying belt 16 conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com