Environmental protection and constant temperature vacuum double layer fire pot

A constant temperature and vacuum technology, used in other medical devices, heating appliances for treatment, cooling appliances for treatment, etc., can solve the problems of no cupping heat, inconvenient cupping methods, etc., and achieve the effect of restoring function well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

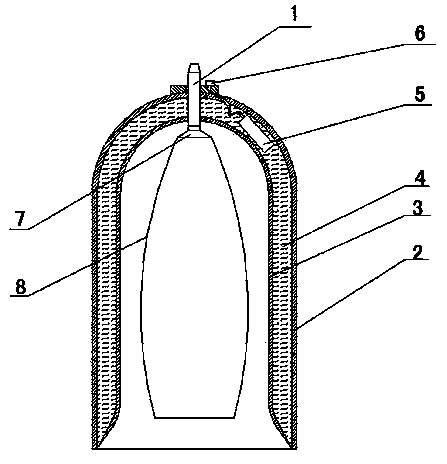

[0021] see Figure 1~2 , a cavity is formed in the tank wall of the vacuumized tank body, so that the tank wall is divided into an inner wall 3 and an outer wall 2, a heat conductor 4 is arranged in the cavity, and a heating device 5 is installed in the heat conductor body; the heating device passes through a wire and a power supply The socket 6 is connected together, and the power socket is connected with a 5~12V DC power supply.

[0022] An annular magnetic block 7 is arranged at the air suction port of the vacuumized tank body.

[0023] A conical net pocket 8 is provided at the air suction port of the vacuumized tank body.

[0024] The heat conductor is heat conduction oil.

[0025] The heating device is a constant temperature heater with a temperature sensor.

[0026] Its use method is as follows: connect 5V DC power supply or 12V DC power supply, preheat the present invention, when the predetermined temperature is reached, use a vacuum cupping device to perform body cu...

Embodiment 2

[0030] see Figure 1~2 , a cavity is formed in the tank wall of the vacuumized tank body, so that the tank wall is divided into an inner wall 3 and an outer wall 2, a heat conductor 4 is arranged in the cavity, and a heating device 5 is installed in the heat conductor body; the heating device passes through a wire and a power supply The sockets 6 are connected together, and the power socket is connected to the 220V AC power supply.

[0031] An annular magnetic block 7 is arranged at the air suction port of the vacuumized tank body.

[0032] A conical net pocket 8 is provided at the air suction port of the vacuumized tank body.

[0033] The heat conductor is heat conduction oil.

[0034] The heating device is a PTC heating module with a temperature sensor.

[0035] The method of use is as follows: switch on the 220V AC power supply, preheat the present invention, and when the predetermined temperature is reached, use a vacuum cupping device to perform body cupping, the perso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com