Mixing preparation machine for production of silicone glue

A silicone glue and preparation machine technology, applied in the direction of mixers, mixers with rotating containers, mixer accessories, etc., can solve problems such as low mixing efficiency, insufficient mixing of raw materials, complicated operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

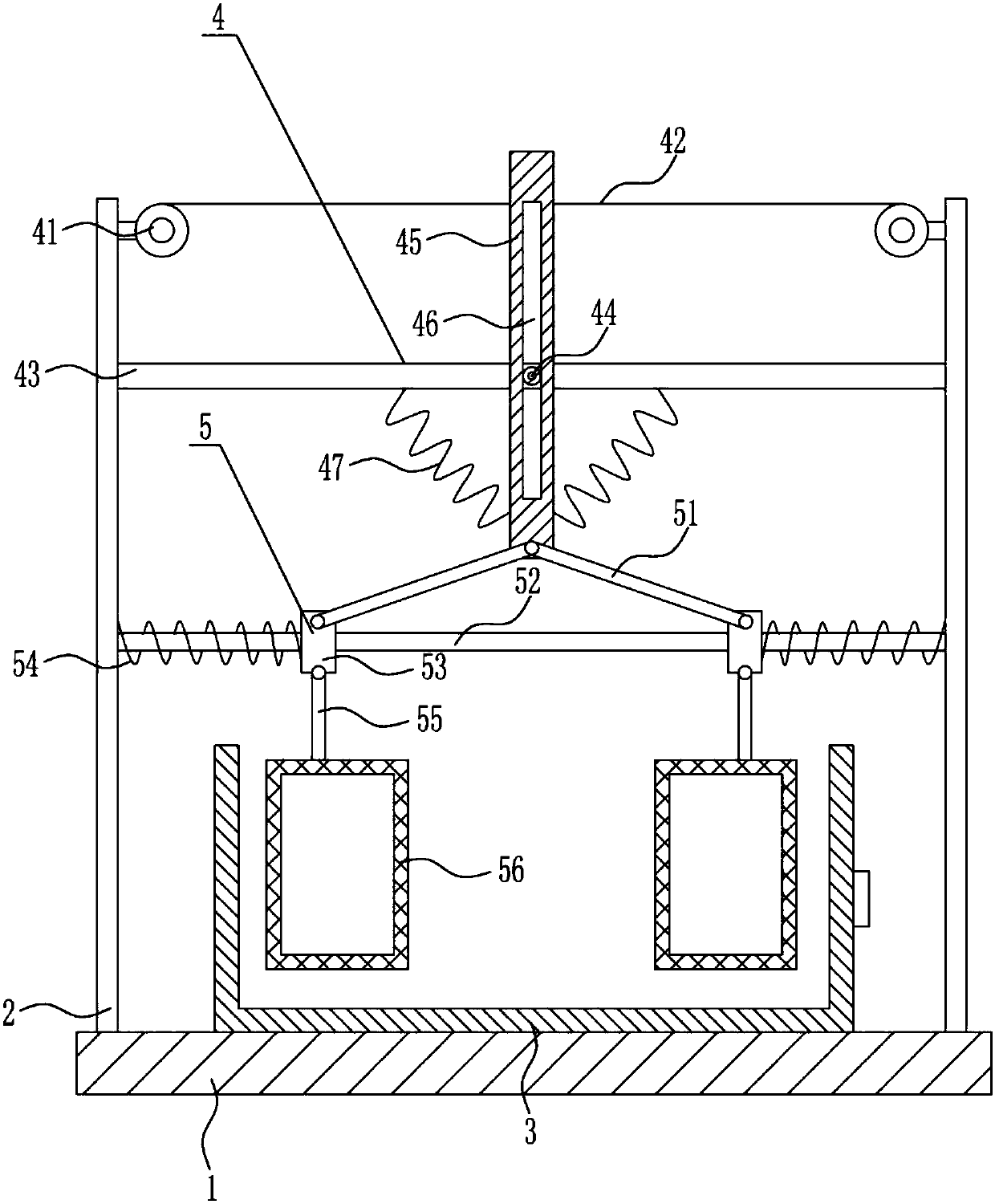

[0031] A mixing preparation machine for the production of silicone glue, such as Figure 1-5 As shown, it includes a bottom plate 1, a support rod 2, a box body 3, a driving mechanism 4 and a mixing mechanism 5. The left and right sides of the top of the bottom plate 1 are provided with a support rod 2, and the upper part between the left and right two support rods 2 is provided with a drive mechanism. 4. A mixing mechanism 5 is provided at the lower part of the driving mechanism 4, and a box body 3 is arranged in the middle of the top of the bottom plate 1, and part of the structure of the mixing mechanism 5 is located in the box body 3.

Embodiment 2

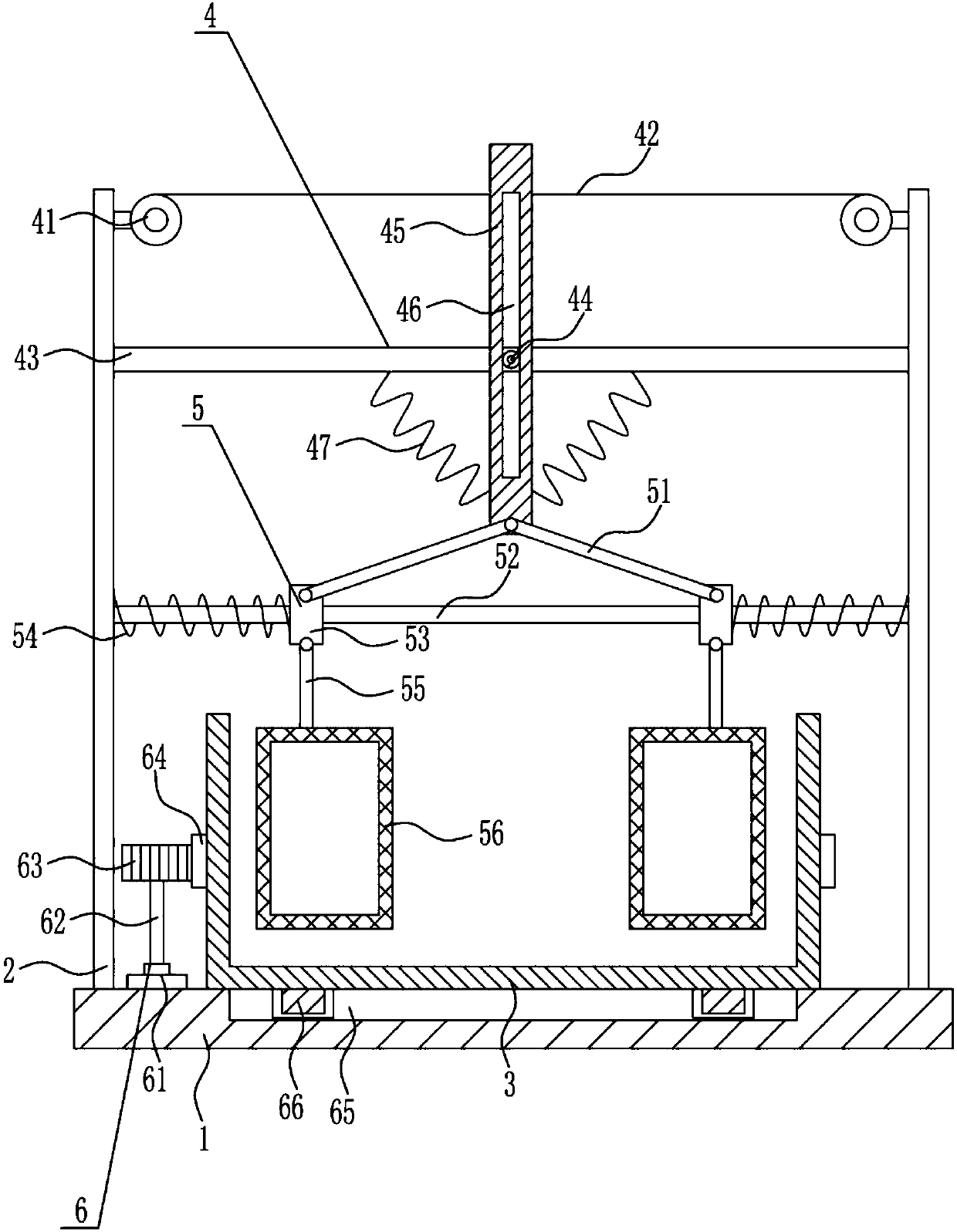

[0033] A mixing preparation machine for the production of silicone glue, such as Figure 1-5 As shown, it includes a bottom plate 1, a support rod 2, a box body 3, a driving mechanism 4 and a mixing mechanism 5. The left and right sides of the top of the bottom plate 1 are provided with a support rod 2, and the upper part between the left and right two support rods 2 is provided with a drive mechanism. 4. A mixing mechanism 5 is provided at the lower part of the driving mechanism 4, and a box body 3 is arranged in the middle of the top of the bottom plate 1, and part of the structure of the mixing mechanism 5 is located in the box body 3.

[0034] Drive mechanism 4 comprises electric reel 41, stay wire 42, cross bar 43, roller 44, swing bar 45 and first spring 47, the right side upper part of left side pole 2 and the left side upper part of right side pole 2 All are provided with electric reel 41, and backguy 42 is wound on the electric reel 41, and the upper part between two ...

Embodiment 3

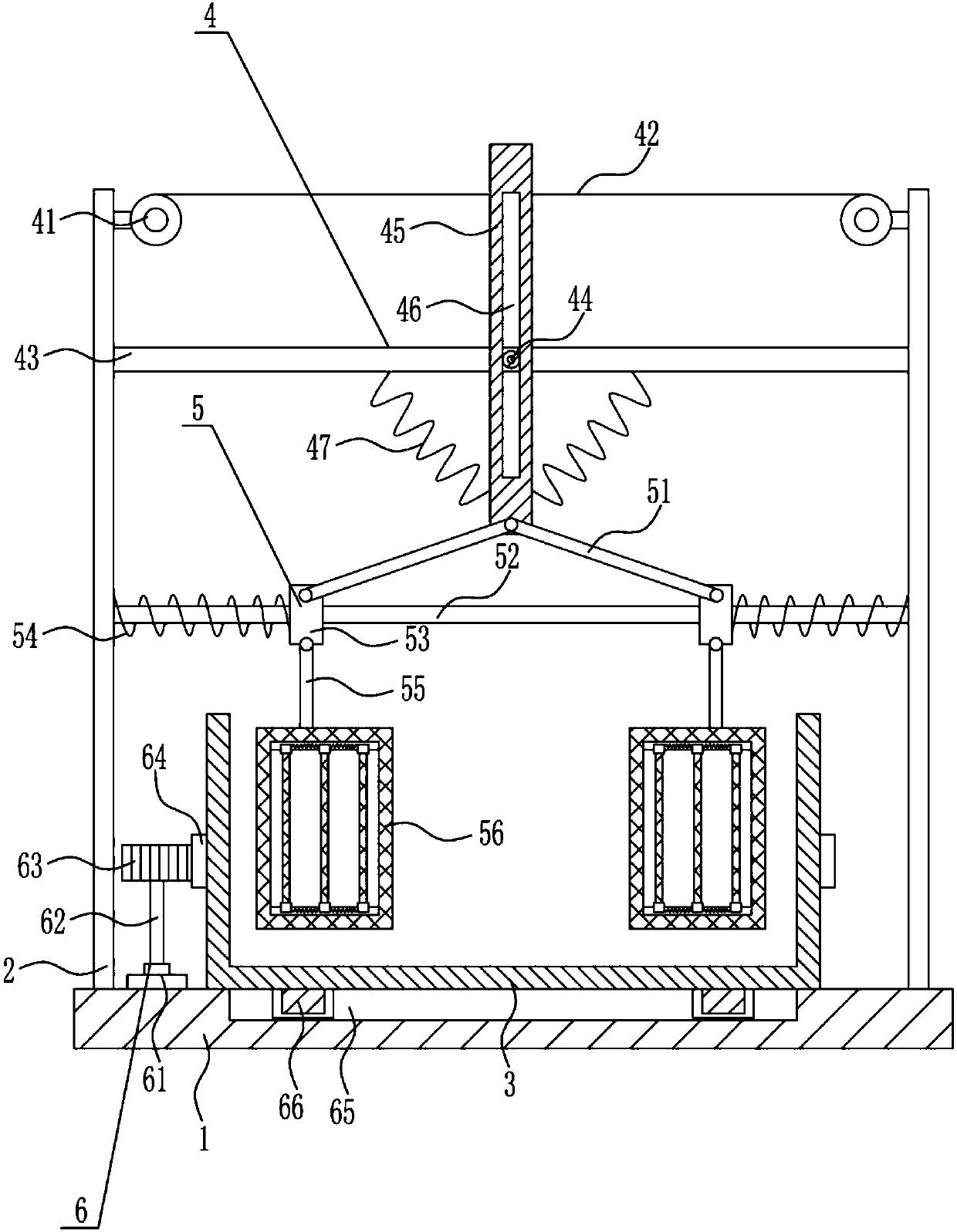

[0036] A mixing preparation machine for the production of silicone glue, such as Figure 1-5As shown, it includes a bottom plate 1, a support rod 2, a box body 3, a driving mechanism 4 and a mixing mechanism 5. The left and right sides of the top of the bottom plate 1 are provided with a support rod 2, and the upper part between the left and right two support rods 2 is provided with a drive mechanism. 4. A mixing mechanism 5 is provided at the lower part of the driving mechanism 4, and a box body 3 is arranged in the middle of the top of the bottom plate 1, and part of the structure of the mixing mechanism 5 is located in the box body 3.

[0037] Drive mechanism 4 comprises electric reel 41, stay wire 42, cross bar 43, roller 44, swing bar 45 and first spring 47, the right side upper part of left side pole 2 and the left side upper part of right side pole 2 All are provided with electric reel 41, and backguy 42 is wound on the electric reel 41, and the upper part between two p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com